GY Face Wash Cream Making Machine Moisturiser Cream Making Machine Stirrer Shaving Cream Liquid Detergent Mixing Tank

Product configuration

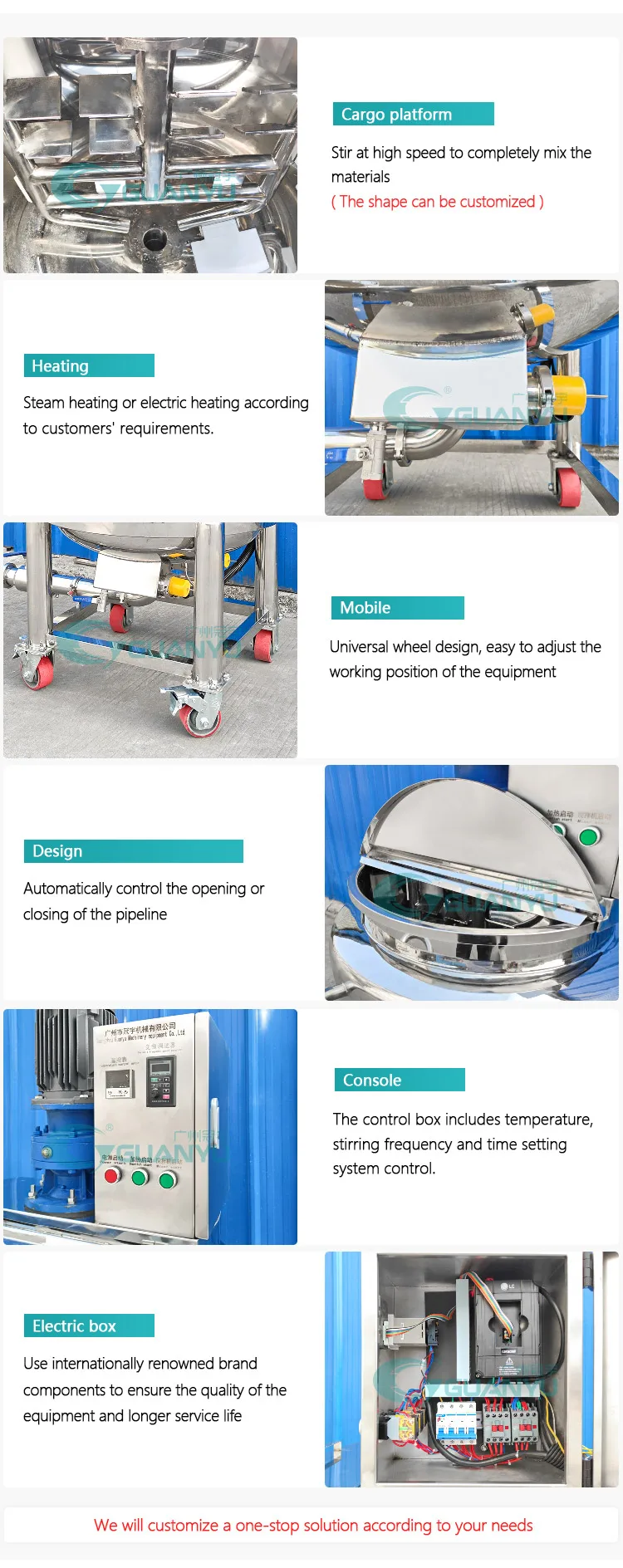

Hand wash liquid soap making machine/stirrer mixing tank /cosmetic cream making machine

The mixing tank means mixing, reconciling, homogenizing, etc., the stainless steel mixing tank can be standardized and humanized in structure and configuration according to the requirements of the production process. The mixing tank can realize feeding control, discharging control, mixing control and other manual and automatic control during the mixing process.

Specification | Working Volume(L) | Heating Method(optional) | Dimension(L*W*H)(m) | Weight(kg) |

GYE-50 | 50 | Electric heating or steam heating | 2.6*2.4*2 | 650 |

GYE-100 | 100 | 2.8*2.5*2.2 | 850 | |

GYE-200 | 200 | 3*2.8*2.3 | 1100 | |

GYE-500 | 500 | 3.3*3*2.5 | 1500 | |

GYE-1000 | 1000 | 4.2*3.5*3.8 | 2500 |

Features:1. The material of contacted part is SUS316L stainless steel, inside and outside of the equipment are with mirrorpolishing and get to GMP standard.2. All pipelines and parameter are controlled automaticlly. And the electric appliance which are imported from foreigncountry,like Siemens ,Schneider and so on.3. Emulsifying tank is with CIP cleaning system,it make the cleaning to be easy and effective.4.Emulsifying tank adopts tertiary agitating system, and during the emulsification ,the whole processing is under a vacuum environment, so it not only can eliminate spume which created in the emulsification processing ,but also can avoid the unnecessary pollution.5. The homogenizer adopts the most advanced technology,it can get a ideal emulsifying effect.The speed of high emulsification is 0-3600r/min, and the speed of low mixing is 0-63r/min.

Product configuration

About Us

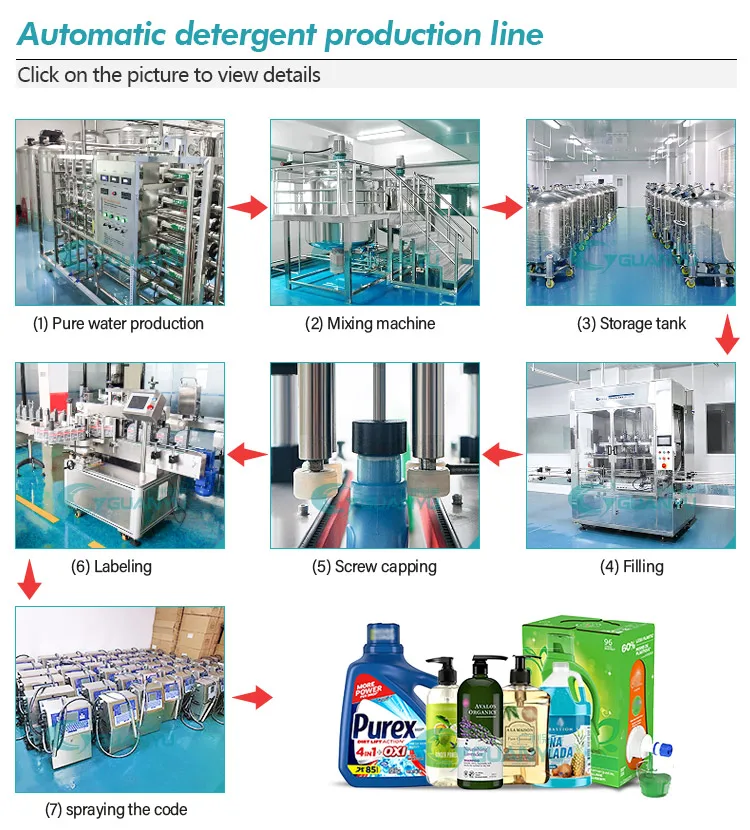

Successful case process

Certifications

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, chemical equipments over 20 years.

Q2: Where is your factory location? How can I visit there?

A2: Our factory is located in Guangzhou, China, welcome to visit us at any time. You can take the plane to Guangzhou and then we will pick you up there.

Q3: How does your factory do regarding quality control?

A3: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q4: What’s the guarantee and the after service if we purchase from you?

A4: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q5: Are your machines difficult to operate? How do you teach us to use the machine?

A5: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines’ functions and to teach you how to use them.

Q6: Can you make the machine according to customers’ request?

A6: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer’s requirements or situation.

Reviews

There are no reviews yet.