Standard Liquid Bath Soap Making Machine Cosmetic Lotion Cream Gel Paste Stirring Blend Vessel Industrial Mixing Equipment

Product configuration

|

Item Name

|

Standard Liquid Bath Soap Making Machine Cosmetic Lotion Cream Gel Paste Stirring Blend Vessel Industrial Mixing Equipment

|

|

Item NO.

|

GYM-2000

|

|

Material

|

SUS316L/SUS304

|

|

Warranty service

|

1 year

|

|

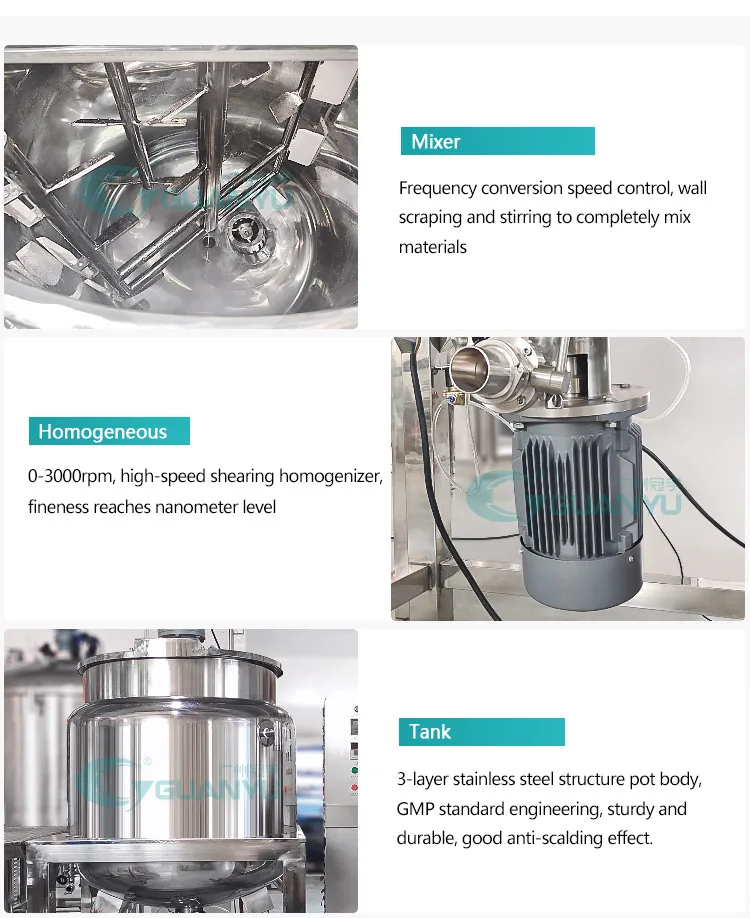

Mixing Method

|

One-way (bidirectional) frame type scraper stirring

|

|

Homogeneous Mode

|

Bottom Circulation

|

|

Openings Way

|

Side Circulation

|

|

Bearing

|

With Japanese NSK

|

|

Seals

|

With Germany Bergman

|

|

Stirring Parameters

|

With Siemens Motor 7.5KW,Mitsubishi Inverter, Speed 0-63 rev / min

|

|

Homogeneous Parameters

|

With Siemens Motor 15-18.5KW,Mitsubishi Inverter, Speed 0-3600 rev / min

|

|

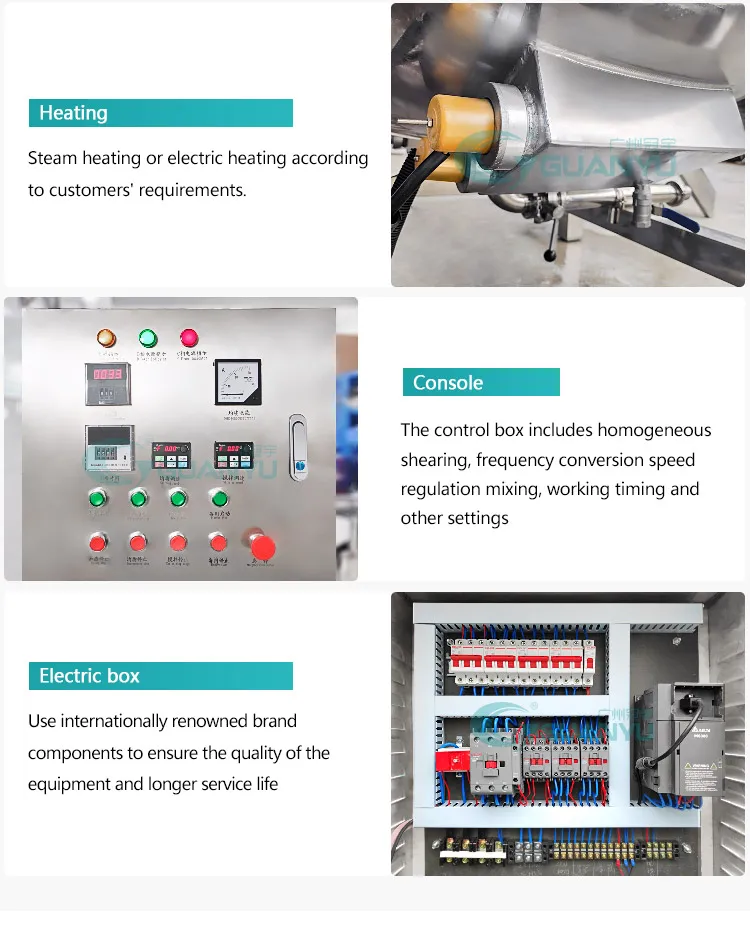

Electrical Components

|

Electric / Steam Heating

|

|

Heating method

|

Electric/Steam Heating

|

1. This company produces the vacuum emulsifying type varieties diverse, including homogeneous system points on homogeneous under homogeneous, both inside and outside circulation homogeneous, mixing system and two-way one-way stirring, ribbon stirring;The lifting system is divided into single cylinder and double cylinder lifting, and can be customized according to customer request a variety of meets the demand of high quality products.

2. Triple mixing adopt imported frequency converter speed control, can meet different process requirements;

3. Homogeneous structure of German technology, using imported double mechanical seal effect, emulsifying speed can reach 4200 r/min, highest the highest shear fineness can reach 0.2 5 um;

4. Vacuum deaeration to achieve aseptic requirements, and USES the vacuum materials, especially for powder material using vacuum suction to avoid dust float in the sky;

5. The main pot pot can choose lifting device, convenient cleaning, cleaning effect is more significant, the pot body can choose the dumping of discharging;

6. Pot body adopted three layers of imports of stainless steel plate welding, tanks and pipelines for mirror polishing, full compliance with GMP requirements;

7. According to the technological requirements, heating and cooling material of tank, steam and electric heating two heating methods mainly include;

8. In order to ensure the whole machine control is more stable, using imported electrical appliances, can fully meet international standards;

2. Triple mixing adopt imported frequency converter speed control, can meet different process requirements;

3. Homogeneous structure of German technology, using imported double mechanical seal effect, emulsifying speed can reach 4200 r/min, highest the highest shear fineness can reach 0.2 5 um;

4. Vacuum deaeration to achieve aseptic requirements, and USES the vacuum materials, especially for powder material using vacuum suction to avoid dust float in the sky;

5. The main pot pot can choose lifting device, convenient cleaning, cleaning effect is more significant, the pot body can choose the dumping of discharging;

6. Pot body adopted three layers of imports of stainless steel plate welding, tanks and pipelines for mirror polishing, full compliance with GMP requirements;

7. According to the technological requirements, heating and cooling material of tank, steam and electric heating two heating methods mainly include;

8. In order to ensure the whole machine control is more stable, using imported electrical appliances, can fully meet international standards;

Product configuration

About Us

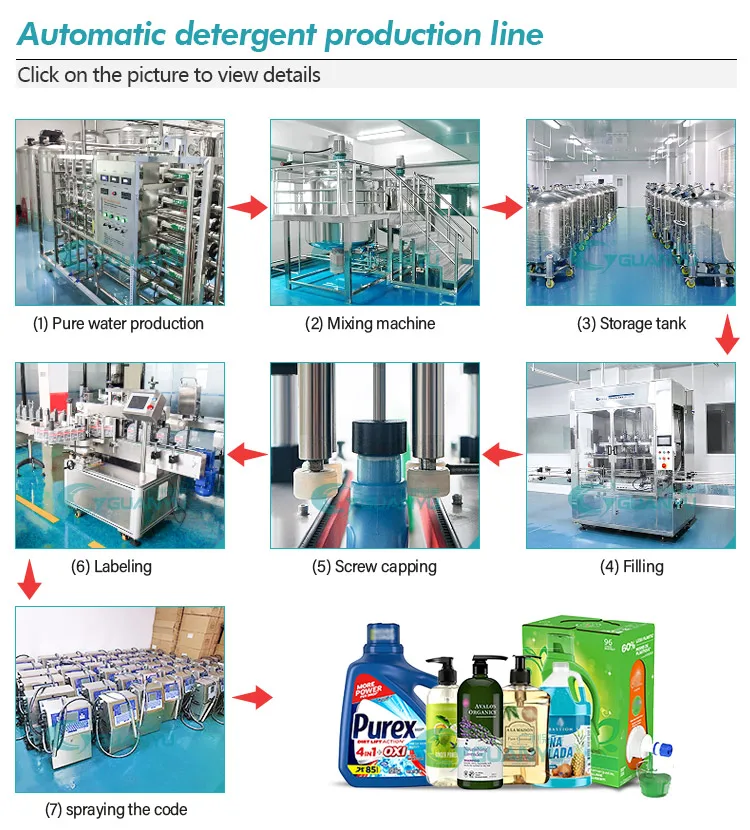

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.