Hot Sale Chocolate Mixer Honey Tomato Ketchup Mayonnaise Mixing Making Machine Homogenizer Vacuum Emulsifying

Products Description

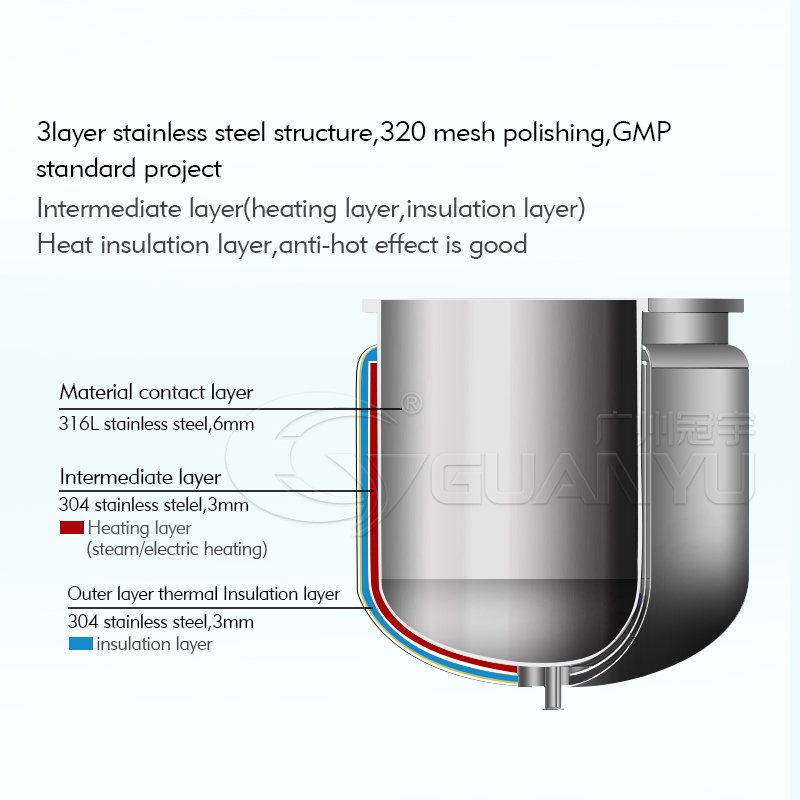

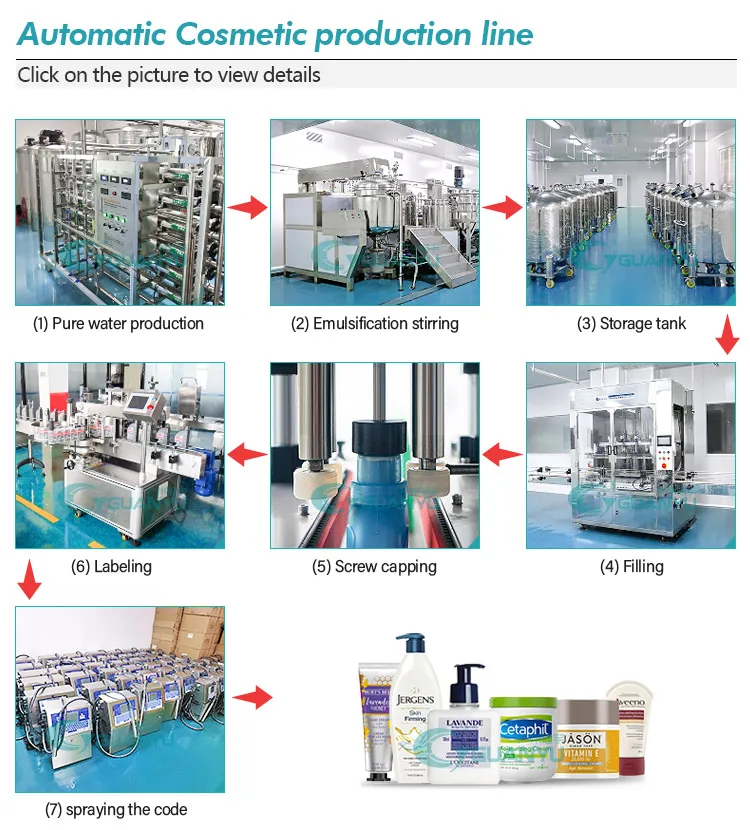

Vacuum emulsifying mixing unit is consisted of homogenizing emulsifying pot (lifting cover, tilting pot body), water pot, oilpot,scraper dual mixing, vacuum system, electric heating or steam heating temperature control system, electric control, etc. It is the equipment for top grade ointment, cream, emulsion.— Cosmetic for cream, shampoo, hair wax— industry for producing ointment—The slurry viscosity can be from low viscosity to high viscosity—Heating, vacuum, cooling all optional— Single emulsifying pot, or with water pot, or oil pot can be selected accrodingly

|

Specification

|

Working Volume(L)

|

Heating Method(optional)

|

Dimension(L*W*H)(m)

|

Weight(kg)

|

|

GYE-50

|

50

|

Electric heating or steam heating

|

2.6*2.4*2

|

650

|

|

GYE-100

|

100

|

2.8*2.5*2.2

|

850

|

|

|

GYE-200

|

200

|

3*2.8*2.3

|

1100

|

|

|

GYE-500

|

500

|

3.3*3*2.5

|

1500

|

|

|

GYE-1000

|

1000

|

4.2*3.5*3.8

|

2500

|

|

Mixing paddle

Frequency conversion speed regulation 0-62r/min, the shape of the blades will be designed according to your materials.

Homogenizer

Frequency conversion speed regulation 0-3000r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Hermetic vacuum

Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product.

Oil-water pot

Pre-treatment System Water phase and oil phase pot to pre-heat and disperse the raw materials, then transfer them to main pot to begin production.

Console

The control panel displays and controls

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

Electric box

Use internationally renowned brand

components to ensure the quality of the

equipment and longer service life

components to ensure the quality of the

equipment and longer service life

Service

We will design drawings according to your

requirements and provide one-stop solutions.

requirements and provide one-stop solutions.

Product configuration

About Us

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.