Our Advantages:

◭ Our own factory: Our factory has 7000 square meters, more than 100 workers, and 6 machine production lines, including machine manufacturing, polishing, and testing.

◭ Customized Machinery: Our main products include fixed vacuum emulsifying machines, mobile homogenizers, all kinds of reaction agitator kettles.

◭ Applicable Products: They are suitable for making cream, lotion, liquid products, including face cream, ointments, ketchup, mayonnaise, jam, hand soap, shampoo etc.

◭ Certifications: CE, GMP, UL and patented technology certificates.

All machines are customized for you!

|

Serve

|

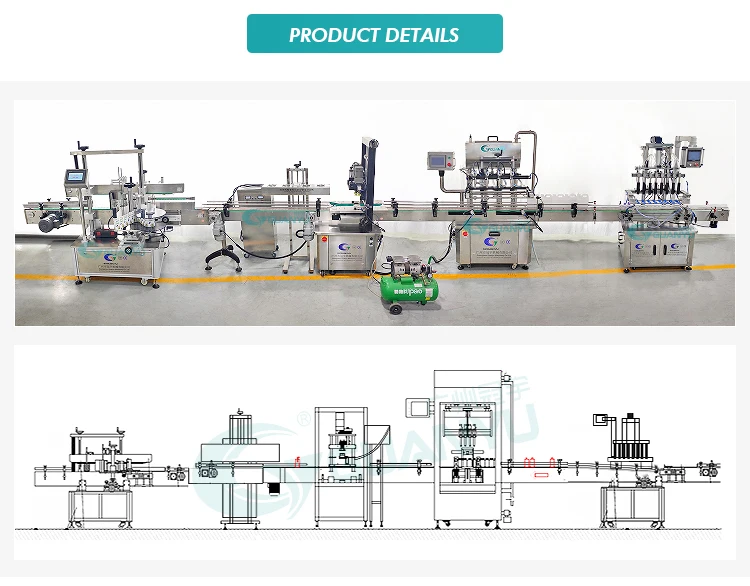

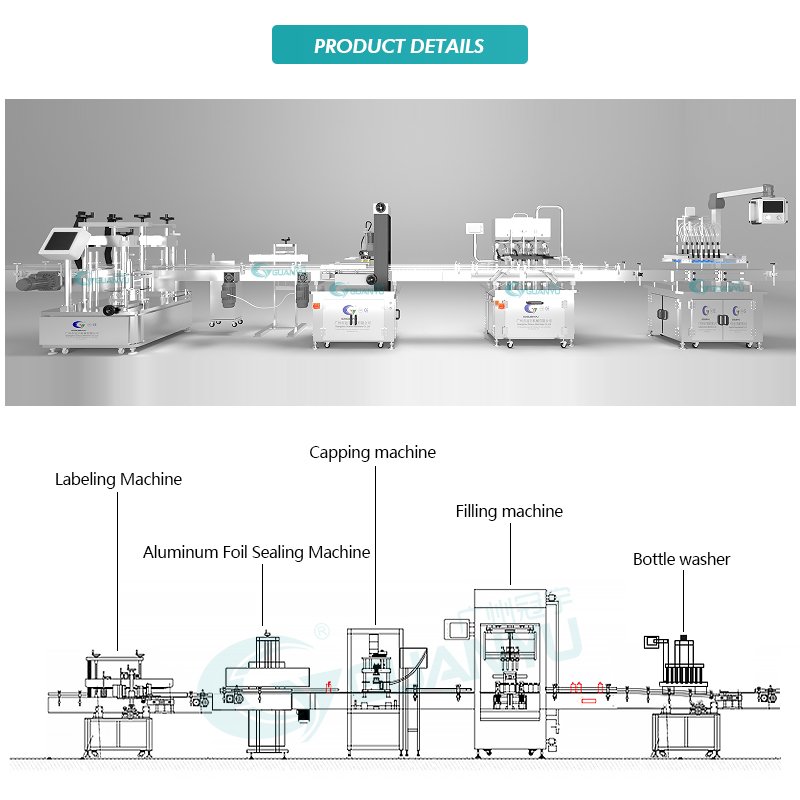

All equipment of the production line can be customized according to customer requirements

|

|

Max filling speed

|

filling 200ml, 2000~3000 pcs/hour, speed will be different when bottle shape and neck size and the filling material forming andother physical property

|

|

Applicable bottle diameter size

|

30-300(mm)

|

|

Applicable bottle height size

|

30-400(mm)

|

|

Filling dose

|

500 ~ 5000 ml (Customizable)

|

|

Filling accuracy

|

±1%

|

|

Voltage

|

110V~680V, can be customized

|

|

Put the bottle

|

Bottle unscrambler automatic bottle release

|

|

Working pressure

|

0.4 – 0.6MPa

|

|

Program control

|

PLC+touch screen man-machine interface

|

|

Capping speed

|

2000-3000 bottles/hour

|

|

Lower cover way

|

Manual or vibrating plate

|

|

Sealed

|

Aluminium foil seal can be added if required

|

|

SLabelling

|

Single-sided/double-sided

|

Main Features(Negative ion dust removal machine):

1. Using precise double filtration, electrostatic ion generation ensures that no dust particles remain in the bottle.

2. Automatically store dust particles to ensure clean room air and operator health.

3. You can set the cleaning time according to your needs;

4. Use double (blow/inhale) mouthwash to remove dust from the bottle;

5. Use a precision filter (0.2um) to ensure the cleanliness of the air source;

6. It is suitable for assembly line operations, and can be matched with various assembly lines, with high efficiency

7. This machine can be used in beverage factories, food factories, chemical factories, cosmetics factories, pharmaceutical factories and other enterprises.

Main Features(Filling machine):

1. The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specificationswithout replacing parts, which can meet the production requirements of multiple varieties and specifications

2. PLC control ,touch bottle operatation ,simple and convenient operation.

3. The use of internatioal famouse brand electrical components, performance and stability.

4. User can adjust filling range, the materials is not enough in hopper, the computer will give the feeding pump signal to

addmaterial by level sensor. When the material is full, the pump will stop automatically.

5. Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

6. Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation.

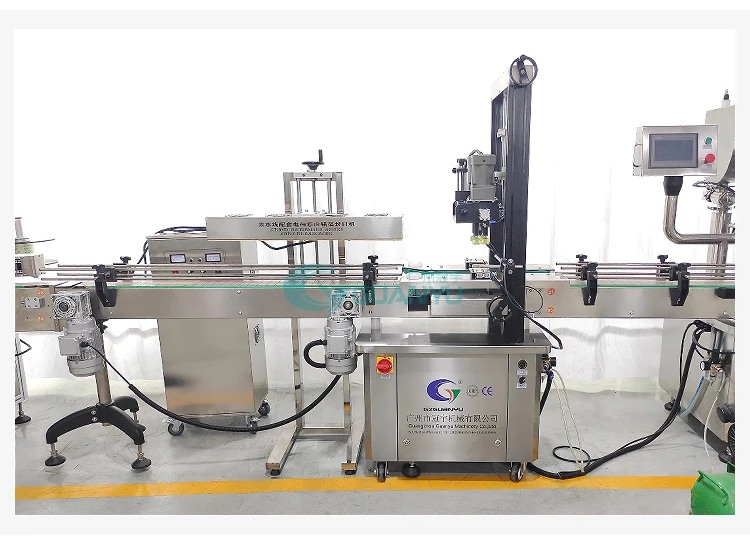

Main Features(Capping machine):

1. The cap elevator and vibrating feeder can be selected according to the shape of the cap and the type of cap

2. Fast capping speed, adjustable from 0-45 bottles/min

3. Bottles and caps of different sizes can share a machine by adjusting or changing a few accessories

4. The tank body of the equipment does not rotate when the cap is screwed, which avoids the displacement, scattering and possible damage of the products contained in the tank.

5. which applied for different cap in different material and different specifications.

6. which use 3-roller type capping knife ,it is easy to regulate the pressure.

7. which applied for metal cap ,screw type cap , pilfer-proofcap, compression cap, etc…

Main Features(Labeling Machine):

1. Improve production efficiency, 20-60 pieces/min

2. The whole machine is made of S304 stainless steel and high-grade aluminum alloy, which meets the production requirements of GMP

3. Controlled by PLC man-machine interface, data can be saved, and the data can be directly called when changing the bottle

4. This machine has the mechanism of bottle guiding, bottle dividing, labeling, wheel leveling, counting and so on.

5. Wide range of application, labeling position, height and angle can be adjusted.

6. It can be connected to the conveyor belt to be used in the production line

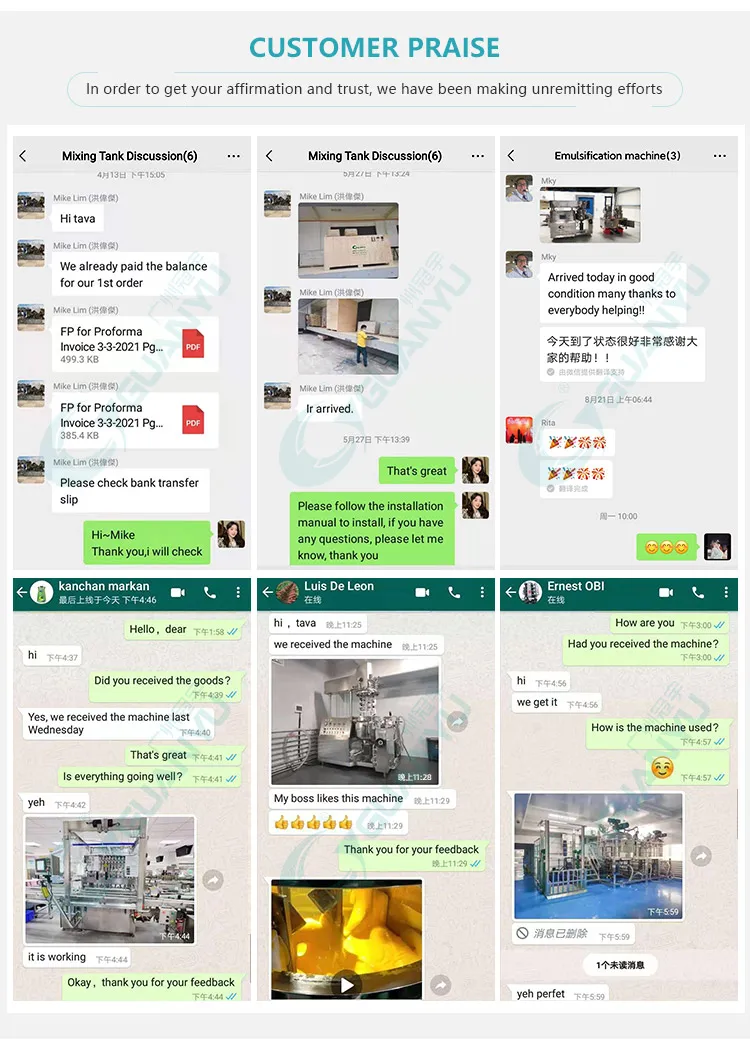

A:Yes we are a factory with more than 23 years manufacturing experience.One is in Jiangsu Province,Another is in Guangzhou next to our office.Q:I’m new in our industry,but I’m planing to set up a factory,what can I do?

A:We will design the most suitable proposal based on your actual situationsuch as the daily production,raw material formula, factory layout,etc.Also we would like to intro-duce some excellent suppliers of raw materials,bottles, labels,etc if needed.After sales,engineer will be send to fields installation,training and commissioning.

Q:How long is your warranty?After warranty,what if we encounter problem about the machine?

A:Our warranty is one year. After warranty we still offer you lifetime after-sales service,anytime you need we are there to help. If the problem is easily to solvewe will shoot asolution video for you. If video doesn’t work out, we will send engineer to your factory.

Q:How can you control the quality before delivery?

A:First,our component/spare parts providers test their products before they offer com-ponents to us.Besides,our quality control team will test machines performance or running speed before shipment. We would like to invite you come to our factory to verify machines yourself. If your schedule is busy. we will take a video to record the testing procedure and send the video to you.

Q:Are your machines difficult to operate? How do you teach us using the machine?

A:Our machines are fool-style operation design,very easy to operate. Besides,before delivery we will shoot instruction video to introduce machinesfunctions and to teach you how to use them. If needed engineers are available to come to your factory to help install machinestest machines and teach your staff to use the machines.

Q:Can I come to your factory to observe machine running?

A:Yes, customers are warmly welcome to visit our factory.

Q:Can you make the machine according to buyer’s request?

A:Yes,OEM is acceptable. Most of our machines are customized design based on customer’s requirements or situation.

Reviews

There are no reviews yet.