You want your mayonnaise production line to work well and give the same results every time. Factory managers like you pick machines from brands they trust and look for new technology. Food safety rules are important to you. You also care about how reliable and flexible the equipment is when you choose it. The Custom Making Machine from Guangzhou Guanyu is special because it has advanced features and good support, so it is a smart choice for making mayonnaise.

Key Takeaways

Pick machines that fit your factory’s needs. Some machines make small batches. Others can make a lot at once.

Automation helps make things faster. It also lowers labor costs. Automatic machines can save up to 40% in costs.

Make sure machines follow food safety rules. Check for safe materials and needed certificates. This keeps your brand safe.

Choose machines that are simple to clean. Easy cleaning keeps things hygienic. It also stops contamination.

Think about how machines help im Laufe der Zeit. The price may be high at first. Automation and reliability save money later. They also help you make more products.

Mayonnaise Production Line Selection Criteria

Produktionskapazität

You need machines that fit your factory’s goals. There are many choices in the food processing industry. Some industrial food processing equipment can make 500 Zu 5,000 Liter each hour. Other machines work with smaller batches from 25 Zu 1,000 Liter. The table below shows some common capacity ranges:

Maschinentyp | Kapazitätsbereich (liters/hour) |

|---|---|

Maschine zur Herstellung von Mayonnaise | 500 Zu 5,000 |

Maschine zur Herstellung von Mayonnaise | 25 Zu 1,000 |

Stainless Steel Mixing Tank | 50 Zu 20,000 |

Automatisierungsfunktionen

You can make work faster with automatic or semi-automatic machines. Fully automatic machines need fewer workers and can cut costs by up to 40%. These machines also help stop mistakes and keep the product the same every time. The level of automation is important because it lets you work longer and find problems early.

Tipp: Most companies say automation makes work 70% faster.

Food Safety Standards

You must follow food safety rules to sell mayonnaise in big markets. Machines should be made with food-safe materials like stainless steel. Look for certifications such as Codex Alimentarius, FDA mayonnaise rules, and the European Union’s V-Label. These rules protect your brand and keep your products safe.

Reinigung und Wartung

Cleanliness is very important at every step. Machines that are easy to clean help you follow hygiene rules and stop germs. Hier sind die steps for cleaning:

Take off any leftover food from surfaces.

Mit warmem Wasser abspülen.

Use detergent to clean off fat and protein.

Rinse again.

Check and clean any dirty spots.

Sanitize to kill germs.

Let the machine air dry to stop germs from coming back.

Kosten und Wert

You want machines that give you gutes Preis-Leistungs-Verhältnis. Fully automatic machines cost more at first, but they save money later. Buying automation helps you meet demand and have less downtime. Prices go from $508 for small machines to $26,888 for big systems.

Skalierbarkeit

Your factory might get bigger, so you need machines that can grow with you. New machines let you make more mayonnaise and try new recipes, like plant-based mayonnaise. Automation and digital controls make it easy to grow and stay ahead. Clean and flexible machines help you keep up with what the market wants.

Leading Mayonnaise Making Machine Profiles

Guangzhou Guanyu kundenspezifische Herstellungsmaschine

You need a machine that does more than mix. The Guangzhou Guanyu Custom Making Machine is special because it can handle big jobs. It works for many products, not just mayonnaise. This helps your factory grow and change with new trends.

Here is a table that shows how this machine compares to others:

Besonderheit | Guangzhou Guanyu kundenspezifische Herstellungsmaschine | Other Mayonnaise Production Line Machines |

|---|---|---|

System Type | Integrated, high-capacity | Variiert |

Product Line Compatibility | Multi-product lines | Typically single-product |

This mayonnaise making machine uses advanced technology. It has reactors, Emulgatoren, mixing tanks, vacuum emulsifiers, und Homogenisatoren. You can add filling, Capping, and labeling machines if you want. The company gives good support, like help with setup and training. You get a two-year warranty and lifetime maintenance. This means your machine will last a long time.

Notiz: You can ask for special features to fit your factory. The technical team will help you set up and use the machine.

Probst & Class Mill

Probst & Class is known for making strong mills. These machines use high-shear mixing to blend oil, Eier, und Essig. This makes smooth mayonnaise every time. Many factories use these mills because they are tough and easy to care for.

You can pick the size that fits your needs. The Probst & Class Mill works for small or big batches. It is easy to clean and meets food safety rules. Many people like its strong stainless steel body. You can count on this machine for steady mayonnaise production.

Industrial Vacuum Processing System

You want your mayonnaise to taste good and last long. The Industrial Vacuum Processing System helps you do this. It uses vacuum technology to mix and process the ingredients. This gives mayonnaise a better taste and texture.

Here are some advantages of this system:

Vorteil | Beschreibung |

|---|---|

Improved Quality | Enhances the quality and taste of mayonnaise and other sauces. |

Stabilität | Ensures longer shelf life and stability of the final product. |

Vielseitigkeit | Can be used in various food production fields beyond mayonnaise, such as ice cream and sauces. |

This system does many things like high shear mixing, Vakuumentgasung, Heizung, und abkühlen.

It makes stable emulsions under vacuum, which helps make more mayonnaise faster.

The vacuum emulsifier removes oxygen from the mix. This stops problems like bad quality, thickening, or spoilage.

You can use this system for more than mayonnaise. It works for sauces, Cremes, and ice cream too. This machine helps keep your products safe and fresh for a longer time.

Mayonnaise Production Line Machine Comparison

Performance Overview

You want your mayonnaise making machine to be fast and steady. Some machines work much faster than others. Zum Beispiel, ProXES machines can make 6,000 kg of mayonnaise each hour. This speed helps big companies fill large orders. Other machines are slower and make small batches. These are good for new businesses or for testing recipes.

It is important to check if the machine keeps the quality the same every time. The best machines do not need much fixing. This saves you time and trouble. You get more mayonnaise with fewer problems. Here is a simple checklist for performance:

Fast machines help you make lots of mayonnaise.

Small batch machines are good for trying new ideas.

Reliable machines do not break down often.

Good quality makes customers happy.

Pick a mayonnaise making machine that fits what your factory needs.

Feature Table

You should look at the features of each mayonnaise making machine before you buy. The table below shows what each machine can do. This helps you find the right one for your factory.

Maschinenname | Merkmale | Anpassungsoptionen | Garantie & Unterstützung |

|---|---|---|---|

Guangzhou Guanyu kundenspezifische Herstellungsmaschine | Integrated system, reactors, Emulgatoren, mixing tanks, vacuum emulsifiers, Homogenisten, Füllung, Capping, Beschriftung | Ja | |

Probst & Class Mill | Mischen mit hoher Scherung, stainless steel body, Einfache Reinigung, batch flexibility | Limited | Ein Jahr, Fernhilfe |

Industrial Vacuum Processing System | Vakuummischung, high shear, degassing, Heizung, Kühlung, stabile Emulsionen | Ja | Varies by supplier |

The Guangzhou Guanyu Custom Making Machine has many features. It has reactors, Emulgatoren, and mixing tanks in one system. You can add filling, Capping, and labeling machines. Sie erhalten Hilfe beim Setup und Training. The warranty is two years, and you get lifetime maintenance. You can ask for special features too.

The Probst & Class Mill mixes well and is easy to clean. You get a one-year warranty and remote help. The Industrial Vacuum Processing System uses vacuum mixing and makes stable mayonnaise. You can use it for sauces and creams as well.

Food Safety Standards Comparison

You must keep your mayonnaise safe for people to eat. Every mayonnaise making machine should have good safety features. The table below shows what to look for:

Sicherheitsmerkmal | Beschreibung |

|---|---|

Notstopp -Taste | Lets you stop the machine quickly if something goes wrong. |

Guarding Systems | Protects you from moving parts during operation. |

Interlocks | Stops the machine from working if it is not safe. |

Check if your mayonnaise making machine meets food safety rules. Look for machines made with food-safe stainless steel. Make sure the machine has Not-Aus-Taster, guarding systems, and interlocks. These features keep you and your team safe.

Tipp: Always ask your supplier for safety certificates and training. This helps you follow the rules and keep your mayonnaise production line safe.

When you compare machines, use this checklist to see which mayonnaise making machine is best for you. You want good features, strong safety, and support that helps your factory grow.

Pros and Cons Analysis

Guanyu Custom Making Machine

You want a mayonnaise making machine that is strong and lasts long. The Guanyu Custom Making Machine gives your factory many good things. You can see the main good points in the table below:

Vorteil | Beschreibung |

|---|---|

High-Capacity Mixing | Handles 1000L batches with precision for uniform blending. |

Versatile Heating Solutions | Equipped with steam or electric heating for temperature control. |

Corrosion-Resistant | Made of stainless steel for durability in harsh environments. |

Multi-Mode Mixing | Offers gentle blending and high-shear mixing options. |

Dual Heating System | Achieves precise temperature regulation faster than single-source. |

Continuous Operation | Maintains 24/7 operation for high-volume production. |

CE-Certified Safety | Adheres to EU safety and quality standards. |

You can use this mayonnaise making machine for many foods. The strong stainless steel parts make cleaning simple. You can run the machine all day and night. The dual heating system helps you change the temperature fast. You can pick gentle mixing or high-shear mixing. The CE-certified features keep your factory safe. You spend less time cleaning because you can reach every part.

Probst & Class Mill

You want a simple mayonnaise making machine that makes smooth mayonnaise. The Probst & Class Mill uses high-shear mixing to blend things well. The body is made of strong stainless steel for tough jobs. You can clean the machine fast after each batch. You can choose the size that works for you. The design makes cleaning easy with fewer steps. You can trust the mill to work the same every time. Für die Nutzung ist keine große Schulung erforderlich. You spend less time cleaning because the design is simple.

Tipp: Always check the mill after each batch for leftover food. So bleibt Ihre Mayonnaise sicher und frisch.

Vacuum Processing System

You want a mayonnaise making machine that gives you top quality and keeps food fresh longer. The Vacuum Processing System uses vacuum technology to mix things. You get better quality and more even results. Your mayonnaise stays fresh for more days. Less air in the mix makes food safer. You need to clean the system often to keep it working well. Your team must learn how to use the system. You check seals and temperatures a lot. You spend more time cleaning because there are many parts.

Here is a table that shows the good and bad points:

Vorteile | Drawbacks |

|---|---|

Regular maintenance required | |

Enhanced consistency | Operator training necessary |

Extended shelf life | |

Increased efficiency | |

Improved food safety |

You can try new recipes and make old ones better. You get perfect results when you make mayonnaise. You can control the temperature and mixing speed very well. Less air means less spoilage. You must clean every part to keep the system safe.

Factory Size Suitability

Kleine Produktion

You have a small mayonnaise factory. You want machines that make fresh batches fast. In-line mixers are good for you. These mixers keep air out of your mayonnaise. They help you get the same results each time. You do not need to spend much money. You can change recipes easily. The mixer works for thick mayonnaise without extra pumps. The table below shows why in-line mixers are smart:

Maschinentyp | Vorteile |

|---|---|

Great for small batches, Weniger Fehler, keeps product stable, saves ingredients, adapts to recipes |

Tipp: In-line mixers help you save money and keep quality high.

Medium-Scale Production

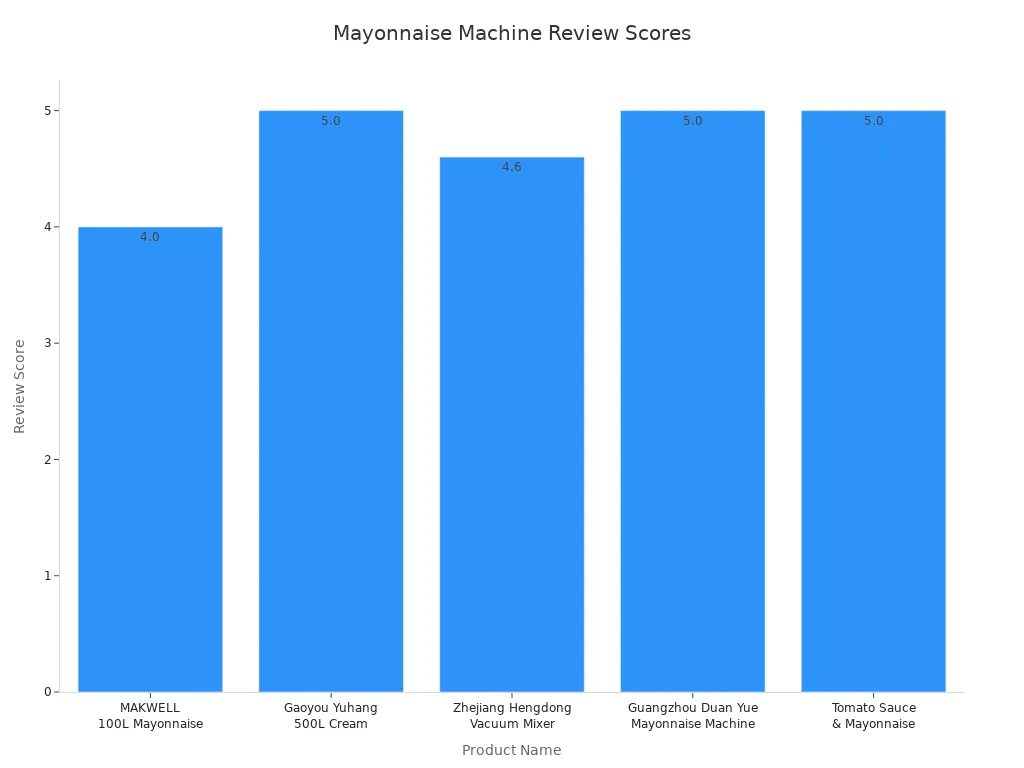

You want to make more mayonnaise and grow your business. Medium-scale machines give you more choices. You can pick machines with vacuum emulsification or filling features. Some machines work for sauces and creams too. Review scores help you choose the best machine. The chart below shows how machines compare:

Some machines have high repeat buyer rates and 24/7 Unterstützung. Some models fit in small spaces. You can pick machines that match your budget and goals.

Large-Scale Production

You run a big factory. You need machines that work fast and make lots of mayonnaise. High-speed homogenizers mix ingredients smoothly. Stainless steel keeps your mayonnaise safe. Vacuum mixing systems help your mayonnaise last longer. You can control the temperature for perfect texture. The table below shows important features:

Besonderheit | Beschreibung |

|---|---|

High-Speed Homogenizer | Reibungsloses Mischen, no lumps |

Edelstahl | Safe for food, stark |

Vacuum Mixing System | Keine Luftblasen, längere Haltbarkeit |

Temperaturregelung | Keeps texture the same |

Multiple Capacity Options | Works for any factory size |

Emulsifying System | Blends oil and water well |

Many big factories use these machines for sauces, Dressings, and ready-to-eat meals.

Specialized Production Needs

You want to make special mayonnaise products. Specialized machines help you do this. You can pick vacuum homogenizer mixers or emulsifying mixers for unique recipes. Some machines fill bottles or sachets for portion control. You can find small machines for tight spaces or fast machines for busy lines. Companies like Micmachinery have solutions for every need. You get accuracy, Geschwindigkeit, und Hilfe von Anfang bis Ende.

RX Vacuum Homogenizer Mixer

RS Vacuum Emulsifying Mixer

RB Vacuum Emulsifier Mixer

Mayonnaise Sachet Filling Machines

Specialized machines help you make new products and meet what customers want.

Cost and ROI Overview

Initial Investment

You need to plan your budget before starting. The cost depends on your plant size and machine type. Hier ist eine Tabelle, die zeigt average starting costs for different plant sizes:

Plant Scale | Initial Investment |

|---|---|

Small-Scale (500 kg/day) | $12–20 hundred thousand |

Mid-Scale (1,000 kg/day) | $20–35 hundred thousand |

Vollautomatisch (2,000+ kg/day) | $40 hundred thousand+ |

You also need to think about other costs. These include land, Maschinen, licenses, Dienstprogramme, Verpackung, and money for daily work. Here is a list of common costs:

Land or plant space: $5–10 hundred thousand

Machinery and equipment: $10–80+ hundred thousand

Licenses and registrations: $50,000–1 hundred thousand

Utilities and infrastructure: $2–5 hundred thousand

Packaging materials: $1–3 hundred thousand

Working capital and miscellaneous: $2–5 hundred thousand

The total cost can be $20 hundred thousand for a small plant. Big, automatic plants can cost over $100 hundred thousand.

Betriebskosten

You need to watch your operating costs every day. These costs include electricity, Wasser, Arbeitskräfte, Zutaten, and fixing machines. Machines with more automation need fewer workers and make fewer mistakes. You spend less on repairs if your machines are reliable. Good machines use less energy and help you work without long stops.

Tipp: Train your staff and do regular checkups. This helps you avoid surprise costs and keeps machines working well.

Return on Investment

You want to know when you will get your money back. Most new mayonnaise production lines take 5 Zu 10 Jahre to pay off. You can get your money back in this time if you run your plant well. Bigger factories usually earn their money back faster because they make and sell more mayonnaise.

You can improve your ROI by picking machines that work fast, break down less, and have good support. Buying good equipment helps your factory succeed and make steady profits for many years.

User Experiences & Case Studies

Real-World Factory Example

You want to know how these machines work in real factories. Let’s look at a medium-sized mayonnaise plant that switched to the Guangzhou Guanyu Custom Making Machine. The factory wanted to make more mayonnaise and keep it tasting good. The team put in the new machine and learned how to use it with help from Guanyu’s staff.

After the change, the factory saw big improvements:

Production speed went up by 30%.

Workers cleaned faster because the machine was simple to wash.

The plant made more mayonnaise and had fewer mistakes.

The machine worked with different recipes, so the factory could try new products.

The manager said, “We fill and pack jars faster now. Our customers get the same quality every time.” You can see that a good machine helps you finish orders and keep your brand strong.

User Testimonials

You want to know what other factory managers think about these machines. Here are some things they often say:

Die Maschinen keep working the same way every time.

They fill and pack jars quickly and accurately.

Being reliable and accurate helps meet distributor needs and stops problems.

Ein Benutzer sagte, “Our old machine broke a lot. The new system works well and almost never stops. We trust it to keep up with orders.” Another manager said, “We like that we can switch between mayonnaise and other sauces fast.”

Tipp: Ask your supplier for training und Unterstützung. This helps your team use the machine well and fix small problems quickly.

You can see that picking the right mayonnaise production line machine makes work easier. Sie erzielen bessere Ergebnisse, happier workers, and satisfied customers.

You can pick a mayonnaise production line for your factory. Old systems mix ingredients in a simple way. Neue Maschinen im Einsatz advanced emulsification to make mayonnaise better. Modern equipment helps keep the quality and texture the same. It makes oil droplets smaller, so mayonnaise is thicker and more stable. Innovative technology gives you better results. When you choose a mayonnaise making machine, check for strong food safety rules. Make sure it is easy to clean and can be changed to fit your needs. Think about getting help for a long time and how the machine can grow with your business.

Key takeaways:

Advanced machines make work faster and improve quality.

Custom features and good support help your factory do well.

FAQ

What materials should my mayonnaise production line machine use?

Pick machines made with food-grade stainless steel. This metal does not rust. It keeps your mayonnaise safe. Stainless steel is simple to clean. It follows food safety rules.

How often should I clean my mayonnaise making machine?

Clean your machine after each time you make mayonnaise. Cleaning often stops germs from growing. It keeps your food safe. Always use the cleaning steps in your manual.

Can I use one machine for different sauces?

Ja, many new machines can make mayonnaise and other sauces. You can change recipes by changing the settings. Clean the machine between batches to keep flavors right.

Tipp: Try new recipes in small batches before making a lot.

What support do I get after buying a machine?

Most companies help you set up your machine. They give training and technical help. Manche, Wie Guangzhou Guanyu, offer a two-year warranty and lifetime care. You can ask their team for help any time.

PH367’s got a chill vibe. Not the biggest selection, but what they have is solid. I had a good run on their roulette. The customer support was quick to help when I had a question. Worth a look if you’re bored. Find out more ph367.