When you choose a soap mixer machine, focus on these top factors: capacity, material compatibility, automation, supplier support, cost, and future growth. The market for these machines keeps growing fast, reaching $528.7 million worldwide in 2025.

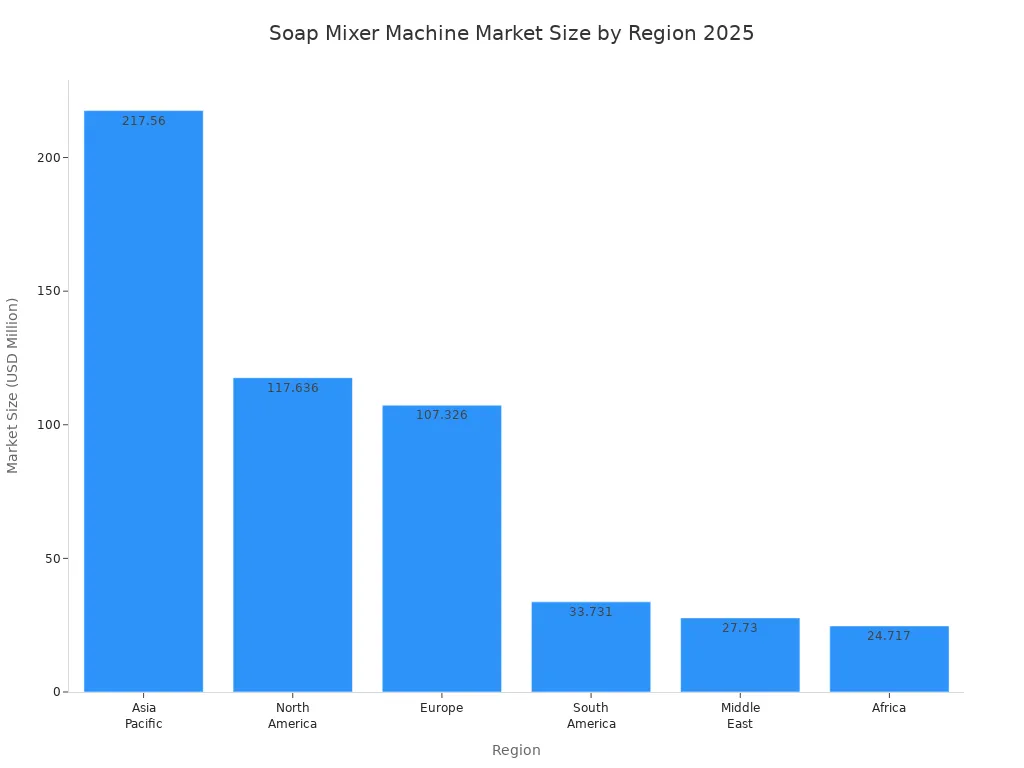

Metric | Value (2025) | Value (2021) | CAGR (2025-2033) | Projection (2033) |

|---|---|---|---|---|

Global Market Size | $528.7 million | $385.56 million | 8.213% | $994.134 million |

Asia Pacific Market Share | 41.15% | $217.56 million (2025) | 8.809% | $427.478 million |

North America Market Share | 22.25% | $117.636 million (2025) | 7.434% | $208.768 million |

Europe Market Share | 20.30% | $107.326 million (2025) | 7.739% | $194.85 million |

South America Market Share | 6.38% | $33.731 million (2025) | 8.511% | $64.837 million |

Middle East Market Share | 5.24% | $27.73 million (2025) | 8.398% | $52.858 million |

Africa Market Share | 4.68% | $24.717 million (2025) | 7.88% | $45.342 million |

You need to match machine features to your soap products and business goals. Look for smart sensors, energy-saving designs, and machines that handle different recipes. Take practical steps and compare options so you can make a confident decision.

Key Takeaways

Choose a soap mixer machine that fits your current production volume and allows room for future growth to avoid costly upgrades.

Look for machines with features that match your soap type, such as adjustable speed, temperature controls, and stainless steel construction for durability and hygiene.

Consider automation levels that suit your business size, from manual mixers for small batches to fully automatic systems for large-scale production.

Select suppliers with strong reputations, good technical support, and quick access to spare parts to keep your production running smoothly.

Plan your budget carefully, including maintenance and operating costs, and prioritize machines with good warranties and long-term value.

Production Needs

Capacity

You should start by looking at your current production volume. Small businesses and startups often choose machines with a capacity of up to 100kg. These machines keep costs low and allow you to make manageable batches. Medium-sized businesses usually need machines that handle 100kg to 500kg. This range balances cost and output, making it easier to grow. Large manufacturers often use machines above 500kg. These machines offer high throughput and automation, but they require a bigger investment.

Capacity Range | Suitable Business Size | Impact on Production Efficiency | |

|---|---|---|---|

Small Capacity | Up to 100kg | Small businesses/startups | Flexible, lower cost, but limited scale and efficiency |

Medium Capacity | 100kg to 500kg | Medium-sized businesses | Good balance of cost and output, supports business growth |

Large Capacity | Above 500kg | Large-scale manufacturers | Maximizes efficiency, high output, needs higher investment |

Tip: Select a soap mixer machine that matches your current needs but also allows for future expansion. This helps you avoid bottlenecks or wasted capacity.

Batch Size

Batch size affects both quality and efficiency. Artisanal soap makers often work with small batches, sometimes as little as 11 to 25 pounds per mold. This size lets you control quality, especially with sensitive ingredients like goat milk. Industrial producers use much larger batches, often 70 to 125 pounds or more. Larger batches save time and reduce labor, but they need bigger molds and special equipment.

If you plan to scale up, think about how your batch size will change. Align your batch size with your production schedule to get the best results.

Growth Plans

You should consider your business growth over the next five years. The soap production market expects a growth rate of about 5.7% each year for small and medium businesses. If you expect to grow, choose a machine that can handle higher volumes in the future. This way, you avoid buying new equipment too soon. Look at mixer comparison tables for different business sizes to help you plan.

Note: Planning for growth now can save you money and time later.

Soap Mixer Machine Features

Mixing Performance

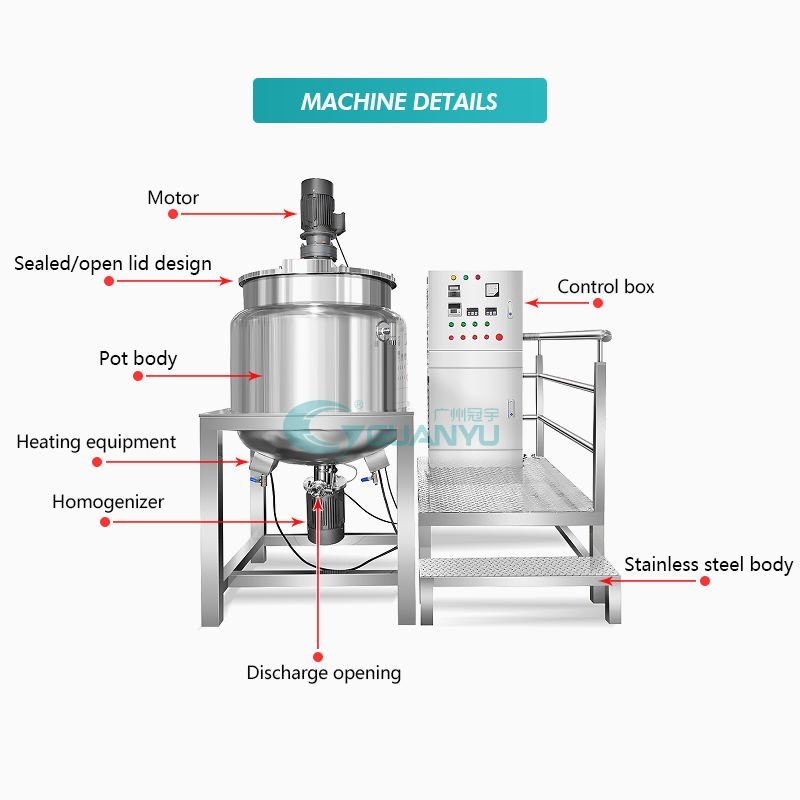

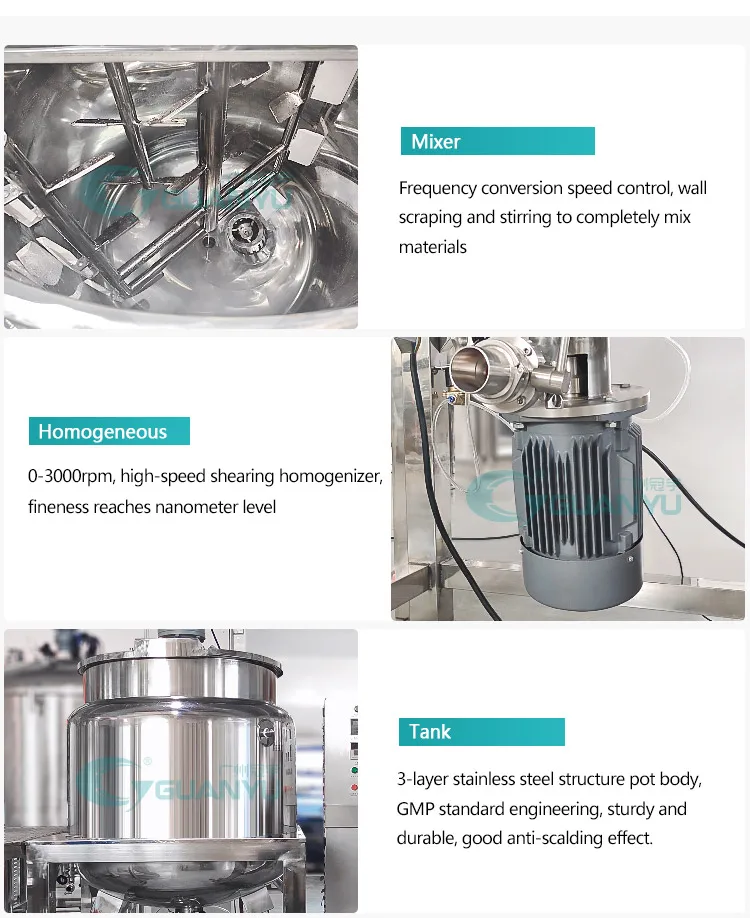

You want your soap mixer machine to deliver consistent results every time. Mixing speed and uniformity play a big role in product quality. Machines with homogenizers blend ingredients more evenly, which helps you achieve a smooth and uniform soap texture. If you work with heat-sensitive materials, vertical batch mixers operate at slower speeds and generate less heat. High-speed mixers, on the other hand, work faster and create a more uniform mix, but they use more energy and can heat up your batch.

Mixer Model Type | RPM Range | Key Features Affecting Speed and Uniformity |

|---|---|---|

Pro Mixers – Large Production | Hands-free, emulsification, multiple mixing wands | |

Slow Speed Mixer | 14 RPM | Gentle mixing, hands-free operation |

Light Commercial Power Wand | 2-speed (Hi & Lo) | Emulsifies, good for small batches |

Commercial Power Wand | 5,000 – 18,000 RPM | High speed, emulsification, large batch suitability |

Pot Whipper | ≥1,200 RPM | Manual attachment, speed varies with drill |

Mixing performance also depends on the viscosity of your soap base. Thick, high-viscosity materials need mixers with higher torque and lower RPMs. Machines with heating options can melt solid fats quickly, speeding up the saponification process. You should choose a mixer that matches your batch size and the type of soap you produce.

Tip: For liquid soaps and lotions, look for customizable speed and temperature controls. For solid bars, sigma mixers with strong blades and heating jackets work best.

Material Compatibility

You need a soap mixer machine that can handle your specific soap formulations. Stainless steel construction is the top choice in 2025. It resists corrosion, stands up to harsh pH levels, and cleans easily. This material keeps your soap pure and prevents contamination. If you use abrasive ingredients or high temperatures, stainless steel ensures your machine lasts longer.

Soap Mixer Machine Feature | Soap Product Requirement / Application |

|---|---|

Matches viscosities and formula properties of liquid soaps and lotions | |

Vacuum homogenizer mixers | Remove bubbles, improve quality in liquid soap production |

High shear mixers | Emulsify and homogenize thick or high-viscosity liquid soaps |

Sigma mixers and double arm sigma mixers | Mix solid soap pellets and additives, handle heat transfer |

Easy cleaning and robust construction | Maintain hygiene, support frequent recipe changes |

You should also check if the mixer can handle both acidic and alkaline ingredients. Some specialty soaps, like those with exfoliants or organic oils, need machines with special coatings or seals. Always match the machine’s material to your soap’s pH and ingredient list.

Automation Level

Automation can transform your production process. In 2025, top-rated machines offer a range from manual controls for small batches to fully automatic systems for large-scale production. Many new models include Industry 4.0 features like IoT controls and AI monitoring. These smart features help you detect problems in real time and boost efficiency.

Common automation features in modern soap mixer machines:

Touchscreen controls for easy operation

Programmable mixing cycles

Real-time monitoring and alerts

Integration with packaging systems

Energy-saving modes

You can choose a manual mixer if you make small, custom batches. For growing businesses, semi-automatic machines offer a balance between control and efficiency. Large manufacturers benefit most from fully automatic machines with remote monitoring and data tracking.

Note: Automation not only saves labor but also improves consistency and reduces waste. Look for machines with strong manufacturer support, warranties, and easy integration with your existing production line.

Supplier and Support

Reputation

When you choose a supplier for your soap mixer machine, reputation matters. A trusted supplier gives you peace of mind and helps you avoid costly mistakes. Look for brands with a strong presence in the market and positive reviews from other businesses. Reliable suppliers often have years of experience and a track record of delivering quality machines.

Suppliers with advanced mixing technology, like variable speed control and temperature regulation, often lead the market.

Hygiene and sanitary design, such as stainless steel construction and Clean-In-Place (CIP) systems, show a supplier’s commitment to safety.

Energy efficiency and automation features, including PLC controls and touch screens, reflect innovation and help reduce labor costs.

Customization options for batch size and operational flexibility are signs of a supplier who understands different business needs.

A supplier’s ability to respond to new trends and regulations shows they can support your business as it grows.

Tip: Always check if the supplier offers strategic collaborations and has a reputation for reliability and product quality.

Technical Support

You need strong technical support after you buy your soap mixer machine. Top suppliers provide engineers who can service machinery, even overseas. Many offer a one-year warranty on core components, free replacement parts, and repair coverage. Some companies, like Wenzhou Qiangzhong Machinery Technology, also provide custom solutions to fit your unique needs.

Manufacturer | Warranty Duration | Coverage Scope | Key Conditions and Exclusions |

|---|---|---|---|

Ready Mixer | 12 months | Defects in material and workmanship | Original owner only; excludes unauthorized repairs, normal wear, improper installation, and secondary owners. |

Abbottstown Industries | 30 days | Replacement for catalog mixers only | Custom builds and electrical components are final sale; returns require original condition and packaging. |

Varimixer | 4 years | Defects in material and workmanship (new equipment) | Registration required; excludes misuse, improper installation, unauthorized repairs, and wear parts. |

Note: Always review warranty terms before you buy. Longer warranties and responsive support can save you money and downtime.

Spare Parts

Quick access to spare parts keeps your production running smoothly. Leading brands, such as Qazi Engineering, keep essential parts in stock and deliver them fast. This means you can fix problems quickly and avoid long delays. When you choose a supplier, ask about their spare parts policy and how fast they can ship replacements.

Ready stock of spare parts ensures minimal downtime.

Fast delivery helps you maintain your production schedule.

Suppliers with a global network can support you wherever your business grows.

Remember: A reliable spare parts supply is just as important as the machine itself.

Cost and Value

Budget

You need to set a clear budget before you buy any equipment. Prices for commercial machines in 2025 vary by size and automation level. Entry-level machines cost between $1,200 and $4,000. Mid-range models range from $5,000 to $15,000. High-end industrial machines can cost $20,000 to over $100,000. The table below shows the average price ranges:

Machine Category | Capacity Range (Liters) | Automation Level | Average Price Range (USD) |

|---|---|---|---|

Entry-Level Machines | Up to 100 | Manual or Semi-Automatic | $1,200 – $4,000 |

Mid-Range Machines | 100 – 500 | Semi-Automatic to Full | $5,000 – $15,000 |

High-End Industrial | 500+ | Fully Automatic | $20,000 – $100,000+ |

Many businesses make mistakes when planning their budgets. Some buy low-quality machines that break down quickly. Others forget to include maintenance or warranty costs. You can see common budgeting mistakes and their impact in the table below:

Budgeting Mistake / Consideration | Explanation | Cost Impact / Notes |

|---|---|---|

Underestimating quality and durability | Low-quality mixers need frequent replacement | Unexpected expenses and production delays |

Neglecting maintenance and warranty costs | Forgetting upkeep and warranty increases long-term costs | Maintenance: $1,000 – $3,000 |

Ignoring new vs second-hand equipment | Not considering used mixers misses savings | Refurbished mixers lower upfront investment |

Overlooking leasing or staggered purchases | Not leasing or phasing purchases strains cash flow | Leasing or staggering helps manage finances |

Missing bundled maintenance deals | Not negotiating packages raises operational costs | Bundled deals offer cost efficiency |

Failing to plan incremental upgrades | Skipping gradual improvements causes big expenses | Upgrades avoid financial strain |

Tip: Always compare new and used machines. Leasing or buying in phases can help you manage your cash flow.

Operating Costs

You must consider monthly operating costs. Utilities like electricity, water, and internet are the main expenses. These costs usually range from $1,000 to $3,000 per month. The amount depends on how much you produce, the season, and how efficient your equipment is. Maintenance and insurance also add to your monthly costs, but utilities are the biggest part.

Note: Efficient machines can lower your utility bills and reduce your total operating costs.

Long-Term Value

Think about the long-term value of your investment. A higher upfront cost often means better durability, fewer repairs, and less downtime. Machines with strong warranties and easy access to spare parts save you money over time. If you plan to grow, choose equipment that can handle larger batches or be upgraded. This approach helps you avoid buying new machines too soon.

Look for:

Durable construction

Good warranty terms

Easy upgrades

Reliable supplier support

A smart investment today can support your business for many years.

Safety and Maintenance

Cleaning

You need to keep your equipment clean to make safe and high-quality soap. Daily cleaning removes leftover soap, oils, and other residues. This prevents blockages and keeps your machine running smoothly. Weekly cleaning routines help you spot early signs of wear or damage. Use food-grade or cosmetic-grade cleaning agents to avoid chemical contamination. Stainless steel surfaces make cleaning easier and help you meet hygiene standards. If you change recipes often, clean the machine between each batch to prevent cross-contamination.

Tip: Clean mixing blades, tanks, and seals after every use. This simple habit extends the life of your equipment.

Safety Features

You should always check for safety features before buying a mixer. Machines that meet CE and FDA standards show they follow strict safety rules. These certifications mean the equipment uses safe materials and protects your workers. Look for emergency stop buttons, safety guards, and automatic shut-off systems. These features help prevent accidents during operation. Touchscreen controls and clear warning labels also make the machine safer to use.

Safety Feature | Why It Matters |

|---|---|

CE/FDA Certification | Ensures compliance and safe materials |

Emergency Stop Button | Allows quick shutdown in emergencies |

Safety Guards | Protects operators from moving parts |

Auto Shut-Off | Prevents overheating or overload |

Maintenance Needs

Regular maintenance keeps your mixer working well and reduces downtime. You should perform daily checks for leaks, loose parts, and unusual noises. Schedule quarterly inspections to catch bigger problems early. Some manufacturers recommend biannual or annual checks, depending on how much you use the machine. Always follow the manufacturer’s instructions for lubrication and part replacement. Common causes of machine failure include blockages, power supply issues, sensor malfunctions, and worn parts. Operator errors and poor environmental conditions, like high humidity, can also cause problems. Well-trained staff and a good maintenance plan help prevent these issues.

Note: Mixing different types of grease can damage electric motors. Always use the right lubricant for your machine.

When you choose a soap mixer machine, focus on your production needs, machine features, supplier support, cost, safety, and maintenance. You should compare options based on flexibility, cost efficiency, and food safety. Many businesses face challenges like maintenance, downtime, and quality control. Align your choice with your business goals and future plans.

Use comparison tools and talk with suppliers to find the best fit for your needs.

FAQ

What size soap mixer machine should you choose?

You should match the machine size to your current production needs. If you plan to grow, pick a model that can handle more volume. This helps you avoid buying new equipment too soon.

How often should you clean your soap mixer machine?

You should clean your machine after every batch. Daily cleaning keeps your soap safe and your equipment in good shape. Weekly deep cleaning helps you spot problems early.

Can you use one mixer for different types of soap?

You can use one mixer for different soaps if you clean it well between batches. Some machines work better with both liquid and solid soaps. Always check the manufacturer’s guidelines.

What safety features matter most in a soap mixer machine?

Look for emergency stop buttons, safety guards, and automatic shut-off systems. These features protect you and your team from accidents. Machines with CE or FDA certification meet strict safety standards.

**gl pro**

gl pro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.info/fr/register-person?ref=T7KCZASX

Needed to log in to raja567, and the login process was smooth enough. No hassles, got straight in. Just what you want, eh? Log in here: raja567login

Yo, x777download is my go-to spot for a quick download fix. Seriously, it always delivers. Check it out: x777download

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.