Emulsifying machines mix liquids like oil and water into smooth blends. These machines are important in industries needing consistent and high-quality products. For instance, they make food textures smoother, improve cosmetics, and help medicines stay even.

The global need for emulsifying is shown in market numbers. In 2020, the emulsifiers market was worth USD 7.99 billion. By 2028, it is expected to grow to USD 13.08 billion, with a yearly growth rate of 6.3%. This shows how industries depend more on emulsifying machines.

Key Takeaways

Emulsifying machines mix liquids like oil and water. They make smooth and stable blends used in food, cosmetics, and medicine.

High shear mixers break liquids into tiny drops. This helps make products consistent and high-quality. They also save time and energy during production.

Different emulsifying machines have special uses. Pipeline emulsifiers mix liquids nonstop, while vacuum emulsifiers make stable mixtures.

These machines make products better, work faster, and help create new ideas. They are important for modern factories.

Picking the right emulsifying machine depends on your needs, materials, and product quality. Taking care of them keeps them working well for a long time.

Understanding Emulsifying Machines

Definition and Purpose

Emulsifying machines are tools that mix liquids like oil and water. They make stable mixtures by breaking one liquid into tiny drops. These drops spread evenly in the other liquid. This is important for making products like mayonnaise, face creams, and ointments.

These machines do more than just mix. They make products smoother, more stable, and consistent. For example, high-shear mixers can create very small droplets, as tiny as 0.5 microns. This helps keep mixtures stable and speeds up production.

Industries use emulsifying machines to meet their needs. Whether it’s food, cosmetics, or medicine, these machines help make high-quality products.

Types of Emulsifying Equipment

There are different types of emulsifying machines for various uses. Each type is made for specific tasks and materials.

Type of Emulsifying Machine | Purpose |

|---|---|

Pipeline Emulsifier | Used for continuous mixing, blending, and smoothing liquids. |

Kettle Bottom Emulsifier | Placed at the bottom of kettles to mix and crush sediments. |

Vacuum Emulsifier | Works in vacuum to make smooth and stable mixtures. |

Inline emulsifiers are a popular choice for high-shear mixing. They use strong forces to break droplets into smaller sizes. This makes them great for precise tasks in cosmetics and medicine.

When choosing a machine, think about your production size, materials, and the quality you need. Each machine type has special features for different jobs.

Role in the Emulsification Process

Emulsifying machines turn two liquids that don’t mix into a stable blend. They use mechanical forces to break droplets and spread them evenly.

High-shear mixers, like rotor-stator systems, are key to this process. They use strong forces to make droplets smaller and keep mixtures stable. Adding emulsifiers helps stop droplets from joining back together.

Industry | Applications |

|---|---|

Pharmaceuticals | Creams, syrups, injections |

Food | Mayonnaise, sauces, creams |

Cosmetics | Lotions, face creams |

Chemicals | Detergents, coatings, polyesters |

For example, in food, these machines keep mayonnaise creamy. In cosmetics, they make smooth lotions and serums. Inline emulsifiers help create consistent results for many products.

Emulsifying machines do more than mix. They improve product quality, save time, and help industries create new ideas. Whether for food or medicine, these machines are key to making reliable and high-quality products.

How Emulsifying Machines Work

High Shear Mixing Principles

High shear mixing is how emulsifying works. It uses strong mechanical forces to break liquids into tiny drops. This helps mix liquids like oil and water into stable blends. Machines like inline emulsifiers are important for this. They use fast rotor-stator movements to create the needed force.

Studies show faster mixing makes smaller droplets and stronger blends. For example, mixing at 4000 rpm creates even, tiny drops that stay stable. But mixing too long can make drops join back together. Three minutes of mixing works best for keeping blends stable.

High shear mixers are used in industries needing exact mixing. Whether for cosmetics, food, or medicine, these machines give steady results.

Key Parts: Rotors, Stators, and Mixing Chambers

Emulsifier machines have three main parts: rotors, stators, and mixing chambers. Each part is important for mixing.

Rotors: These spinning blades create the force to break liquids apart.

Stators: These still parts work with rotors to make strong mixing zones. Different stators, like angle slot ones, are used for specific tasks. For example, emulser stators are great for smooth blends in thin liquids.

Mixing Chambers: These spaces make sure everything mixes well. They also stop leaks and keep things clean.

These parts work together to mix liquids efficiently and accurately.

The Emulsification Process: Speed and Shear Force

The mixing process depends on speed and force. Inline emulsifiers use fast rotors to create strong mixing zones. This breaks liquids into tiny drops and makes stable blends.

Speed and force affect how good the final product is. High shear mixers work quickly, making them perfect for factories. Regular care keeps them working well. Cleaning and checking for problems are important steps.

By learning these basics, you can use emulsifying machines better. Whether for food, beauty products, or chemicals, these machines help make top-quality items.

Key Features of Emulsifying Machines

Efficiency and Precision

Emulsifying machines work quickly and accurately. They use high shear mixers to break liquids into tiny drops. This makes smooth and stable mixtures. Industries like cosmetics and medicine need this accuracy for top-quality products.

These machines are built to save time and energy. Inline emulsifiers mix fast, creating even blends in less time. This helps lower energy use and speeds up production. They are a smart choice for saving money while keeping quality high.

Using industrial emulsifiers improves how much you can produce. It also ensures your products stay consistent and meet high standards.

Versatility for Many Industries

Emulsifying machines are flexible and useful in many fields. They can handle different materials to make custom products.

In medicine, they improve how drugs work and help vaccines.

Paint makers use them for stable, eco-friendly products that follow rules.

Vacuum emulsifiers are great for custom cosmetics and medicines.

Chemical companies use them for adhesives and coatings with steady quality.

This flexibility makes emulsifying machines important for modern factories. They meet the needs of many industries.

Easy to Use and Maintain

Emulsifying machines are simple to use and care for. New designs make them easier to operate and clean.

Feature | How It Helps |

|---|---|

Automatic Lifting System | Makes it easy to remove parts for cleaning. |

Cleaning Features | Speeds up and simplifies cleaning tasks. |

Operational Efficiency | Cuts downtime and keeps production clean and steady. |

Taking care of these machines is important for smooth operation. Automated systems now reduce maintenance time by 34%. Maintenance costs are only 18-23% of yearly expenses. This makes these machines reliable and affordable for businesses.

Choosing advanced emulsifiers helps you work faster and focus on making great products.

Industrial Applications of Emulsifying Machines

Food Industry: Dressings, Sauces, and Dairy Products

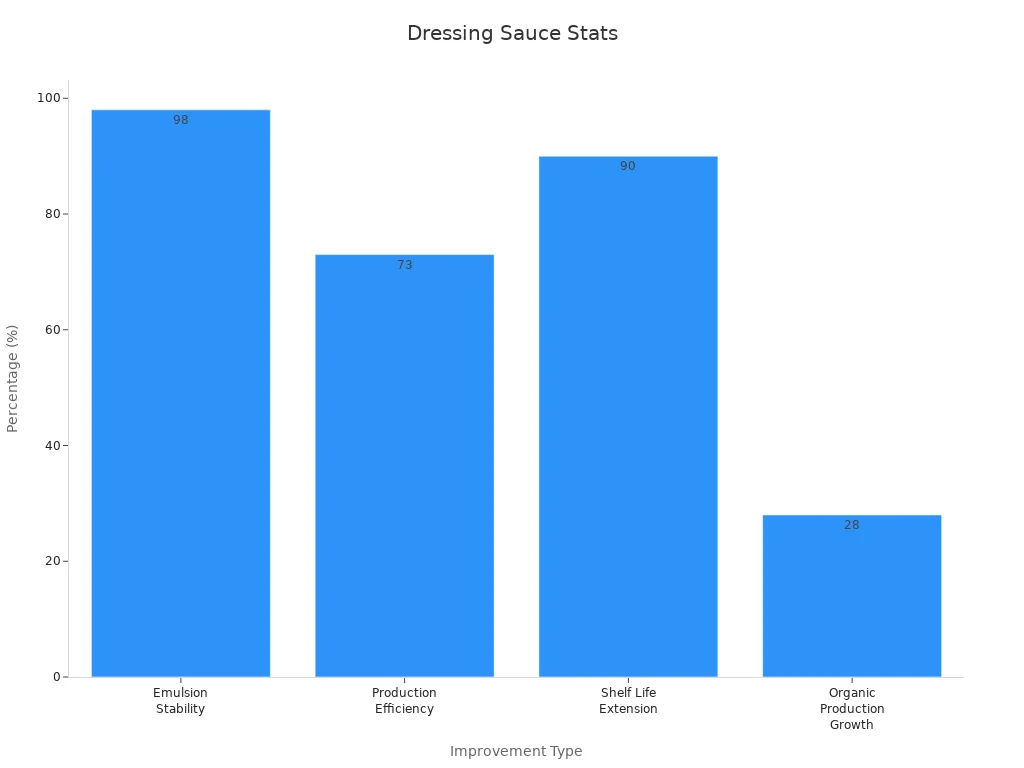

Emulsifying machines are very important in food production. They help mix oil and water-based ingredients smoothly. This creates stable and creamy products like sauces and dressings. For example, high shear mixers can make egg-based sauces 98% stable. This improves both quality and consistency.

New emulsifiers have made production faster and easier. In France and Italy, 73% of new mixers now clean themselves automatically. Vacuum mixers working at 40 PSI remove 90% of oxygen. This keeps food fresh longer and extends shelf life.

Organic food demand is also rising quickly. USDA reports show a 28% increase in organic sauce production since 2020. Emulsifying machines help meet strict rules like FSSC 22000 certification.

Improvement Type | Details |

|---|---|

Emulsion Stability | High-shear mixers achieve 98% stability for egg-based sauces. |

Production Efficiency | 73% of mixers in France and Italy have auto-cleaning systems. |

Compliance with Regulations | CIP systems adopted due to FSSC 22000 certification rules. |

Shelf Life Extension | 40 PSI vacuum mixers remove 90% oxygen, keeping food fresh. |

Organic Production Growth | Organic sauce production rose 28% since 2020, says USDA. |

These changes show how emulsifiers improve food production and product quality.

Cosmetics Industry: Creams, Lotions, and Serums

In cosmetics, emulsifying machines are key for making smooth creams and lotions. They ensure products have the same texture and stay stable. Thick creams need strong mixing, while delicate serums need careful temperature control.

Modern machines use smart controls and clean themselves automatically. This ensures products are smooth and meet customer needs.

Keeps products stable and consistent

Improves customer satisfaction

Helps brands compete better

Allows real-time adjustments during mixing

Inline emulsifiers help make precise products that stand out in the market. They also support eco-friendly production, which many customers prefer.

Pharmaceutical Industry: Ointments, Suspensions, and Gels

Pharmaceutical companies rely on emulsifying machines for making ointments and gels. These machines mix liquids that don’t normally combine. This ensures active ingredients are spread evenly, keeping products effective and high-quality.

Emulsifiers also adjust thickness and water levels for different textures. For example, hydrophilic petrolatum emulsifiers stop ingredients from separating. This makes products last longer and work better.

Quality Control Metric | Description |

|---|---|

Clarity Test | Checks emulsion clarity using light reflection. |

Standard Operating Procedures (SOPs) | Written steps to ensure consistent mixing processes. |

In-Process Control Records | External records to confirm all steps are followed correctly. |

Mixing accuracy is very important in medicine production. Emulsifying machines ensure even textures and reliable results, making them essential for pharmaceutical work.

Chemical Industry: Paints, Lubricants, and Polymers

Emulsifying machines are important in the chemical industry. They help mix liquids evenly for paints, lubricants, and polymers. This improves product quality and makes them more reliable.

How Emulsifying Machines Improve Paints

Smooth paint texture is very important. Emulsifying machines break pigments into tiny pieces. This helps paint spread evenly and stick to surfaces.

These machines also save time by mixing ingredients faster. They prevent paint from separating during storage, keeping it stable.

Lubricants: Perfect Mixing

Lubricants need careful mixing to work well. Emulsifying machines blend oil and water into smooth mixtures. This helps lubricants handle heat and heavy use.

The machines create tiny droplets and spread them evenly. This makes lubricants last longer and reduce friction better.

Polymers: Strong and Reliable

Polymers need precise mixing for good results. Emulsifying machines mix materials thoroughly, making strong and durable products.

They also let you adjust formulas for different uses. Whether for adhesives or coatings, these machines ensure consistent quality.

Benefits for Chemical Production

Emulsifying machines offer many benefits for chemical production.

Benefit | How It Helps |

|---|---|

Uses strong forces to mix liquids that don’t usually combine. | |

Better Product Stability | Tiny droplets and even spreading keep products stable and high-quality. |

Improved Additive Performance | Strong mixing activates additives, making products more stable and effective. |

These features make emulsifying machines essential for chemical industries.

Why Emulsifying Machines Are Important

Emulsifying machines boost efficiency and product quality. They help meet the demand for better chemical products. Whether for paints, lubricants, or polymers, these machines ensure your products succeed in the market.

Emulsifying machines are crucial for making smooth and even mixtures. They help mix ingredients evenly and with control, improving product quality. These machines are essential for modern factories because they ensure consistent mixing. Key advantages include quicker production, better uniformity, and dependable results. Whether used in food, cosmetics, or medicine, they help products meet top quality and innovation standards.

FAQ

What does an emulsifying machine do?

An emulsifying machine mixes liquids like oil and water. It creates smooth, stable mixtures by spreading tiny droplets evenly. This helps make products for food, cosmetics, and medicine.

How can you pick the right emulsifying machine?

Think about what you need to make and the materials you use. Vacuum emulsifiers are great for cosmetics. Inline emulsifiers are better for food or chemical production.

Are emulsifying machines simple to care for?

Yes, modern machines are easy to maintain. Many have automatic cleaning and removable parts, making upkeep fast and simple.

Can these machines work with different materials?

Yes! Emulsifying machines are flexible. They handle thick creams and light serums, giving consistent results for many industries.

Why are high shear mixers useful in these machines?

High shear mixers use strong forces to break liquids into tiny drops. This makes stable mixtures, improves quality, and speeds up production.

Heard Gacor108Slot is where the ‘gacor’ is at! Worth checking out for some potentially big wins. See for yourself: gacor108slot