Small Bottle Filler Vial Manufacturing Filling Accuracy Liquid Automatic Perfume Glass Vial Filling Sealing Capping Machine

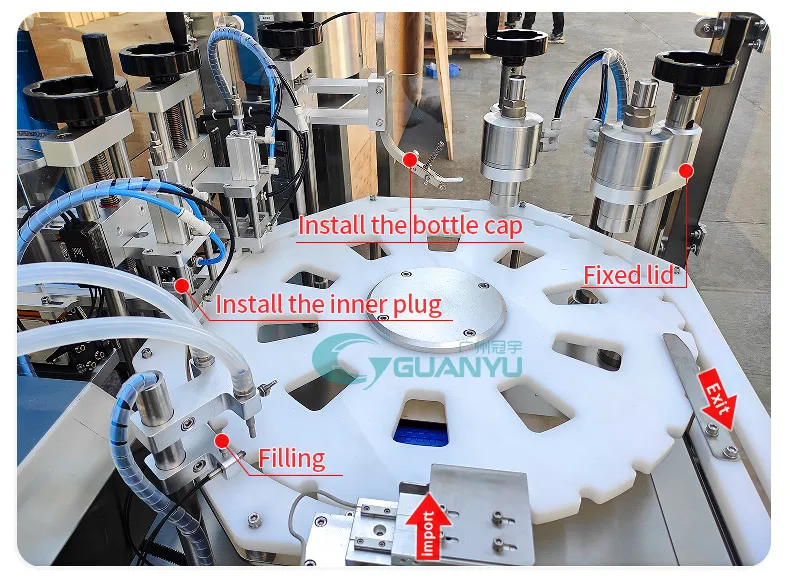

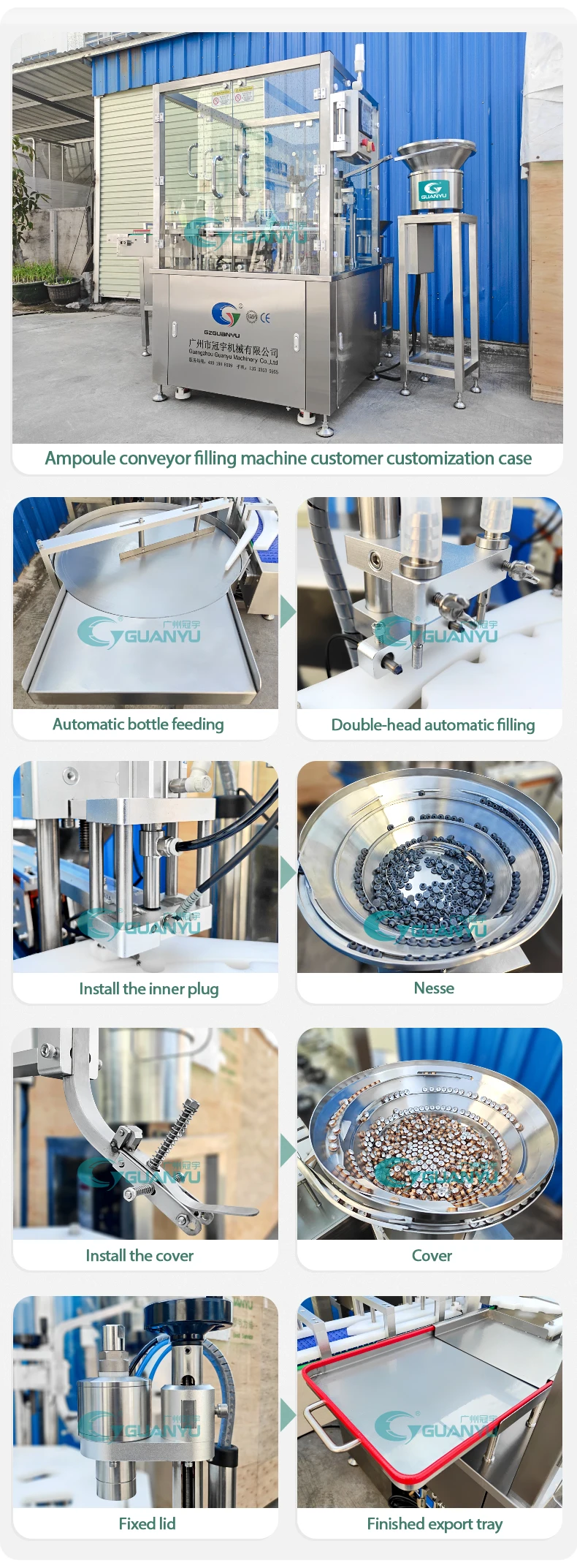

Brief introduction of liquid filling machineThis machine is developed on the basis of introducing and absorbing the foreign advanced technology by our company , is a professional filling capping integrated machine for vials, glass infusion bottles or similar bottles. And at the same time, it can simultaneously completed multiple actions, such as unscramble bottle, 定量填充, stoppering ( Butyl Rubber Stoppers ), capping and sealing, etc.This machine adopts Japanese full imported high precision closed cam indexing station, with high precision, reliable operation and long service life. The protractor has the advantages of simple structure, no maintenance of long-term use.Product Features of Filling Capping machine,10ml vial filling machine1, The machine adopts the disc type unscrambling bottles, automatic feeding bottles2, SIEMENS PLC control system, colored touch-screen display.3, The pressure plug is automatic sorting this stoppers by the vibrating disk, automatic drop plug and plugging, Equipped with device of automatic induction pressure plug, so reliability is higher4, The lock cover machine is also similar, it is automatic sorting by vibration plate, hanging cover and adopted the special lock head, three knife capping, lock port appearance is beautiful .Equipment Advantage of Filling Capping Automatic Vial Liquid Filling Machine1, Adopt the plunger type metering pump to perform filling, so the precision is higher, the structure of the pump is adopted quick connection type dismantling mechanism, easy to clean and disinfect.2, SIEMENS PLC control system, colored touch-screen display.3, No bottles, no filling. And equipped with automatic counting function, more human.4, Filling nozzle is equipped with an anti-drip device (leak proof device).5, When it is located in filling situation, filling nozzle dived into the bottom of bottles and slowly rising, it can effectivelyavoid bubbling.6, Adopt SUS304 and 316L stainless steel manufacturing, Meet GMP.7, Four-in-one, unique design, reliable operation and coordination, good synchronization, it can be stand-alone production, and can be also linked to the production line.

模型 | Automatic Small Bottle Liquid Filling Capping Machine |

Load range | 10-100毫升 |

Load error | less than 1% |

Rotary (rolling) cover qualified rate | 99% |

生产能力 | 30-50 瓶子 / min |

电源 | 380伏/50赫兹 |

力量 | 3 KW |

方面 | 3000*1200*1600毫米 |

净重 | 1000 |

评价

目前还没有评价