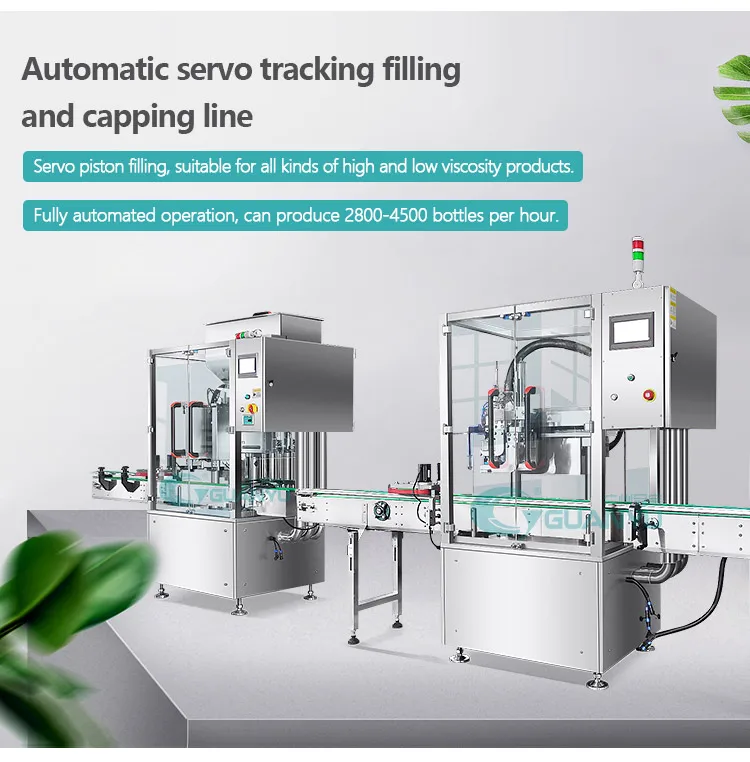

全自动 2 Heads洗发水皂液生产线化学洗手液洗涤剂肥皂灌装旋盖机

产品配置

最大灌装速度 | 灌装200ml, 2000~3000 件/小时, 速度会因瓶子形状和颈部尺寸以及灌装材料成型和其他物理特性而不同 |

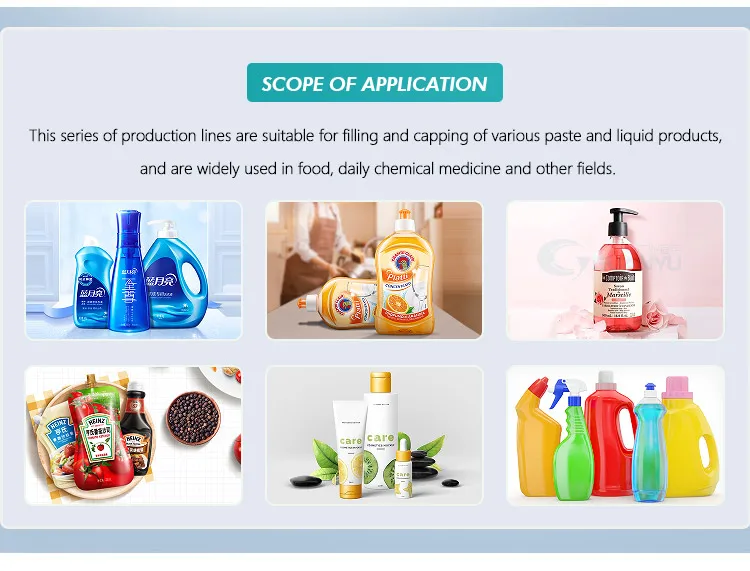

适用瓶径尺寸 | 30-300(毫米) |

适用瓶子高度尺寸 | 30-350(毫米) |

填充剂量 | 200〜2000ml(可自定义) |

灌装精度 | ±0.5% - ±0.8% |

电压 | 交流220V, 单相, 50/60赫兹 |

力量 | 4.5 千瓦 |

工作压力 | 0.55-0.65 兆帕 |

填充方法 | 伺服活塞跟踪 |

程序控制 | PLC+触摸屏人机界面 |

旋盖速度 | 2000-3000 瓶/小时 |

下盖方式 | 手动或振动盘 |

主要特点(灌装机):

1、跟踪填充方法, 在填充过程中,无需像传统方法那样拦截瓶子填充, 而且填充作用在瓶装过程中完成.

1、该机器配备了参数存储系统. 更改瓶子尺寸或填充体积时, 只需按触摸屏上的键进行调整.

2、气缸驱动填充喷嘴的潜水,并与可变填充速度相匹配,这可以减少填充时的泡沫,从而避免污染瓶子.

3、在人机界面上, 可以单独调整不同填充头的填充体积.

4、材料级传感器用于检查机器正常运行下的水平位置,加上高级和低级检查和警报设备. 水平检查设备由PTFE制成, 具有完美的抗腐蚀功能.

5、机身由 304 不锈钢, 易于清洁, 机器完全符合GMP要求.

主要特点(旋盖机):

1.跟踪螺丝封方法, 无需拦截瓶盖时的瓶盖,封盖时的传统方式, 并且瓶盖动作在瓶装过程中完成.

2.该机器配备了参数存储系统. 改变瓶子的大小, 只需按触摸屏上的键进行调整.

3.该机器采用完整的伺服控制, 包括上限头的高度, 上限爪的翻译速度, 和上限扭矩控制.

4.根据不同的包装材料, 您可以选择使用不同的上限头.

5.采用身份扭转封盖头, 上限设备不会伤害帽子 .

6.可以与包装线匹配.

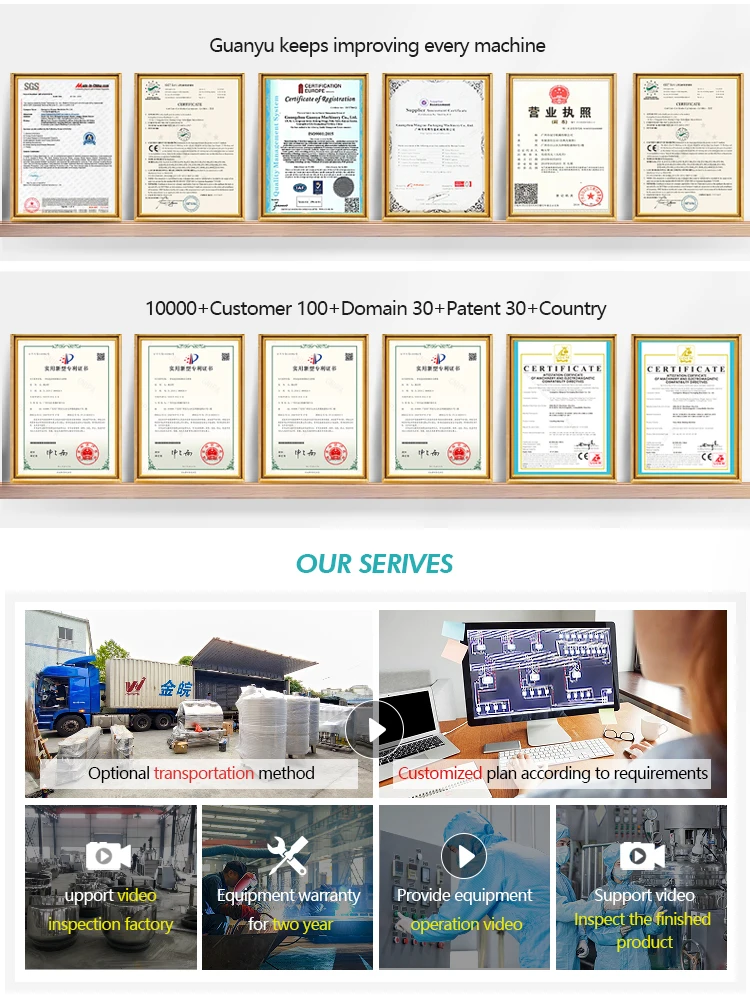

关于我们

认证证书

常问问题

评价

目前还没有评价