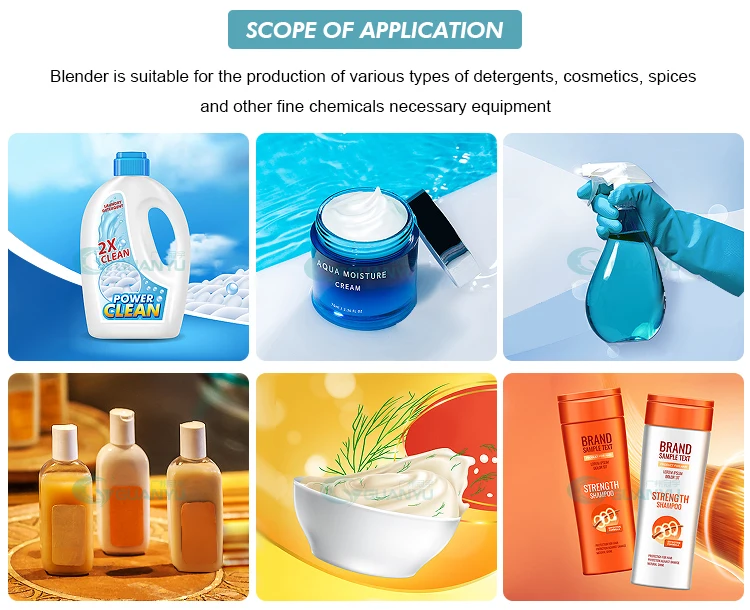

定制5000L液体洗涤剂混合机洗涤剂生产厂化学液体皂混合罐制造机

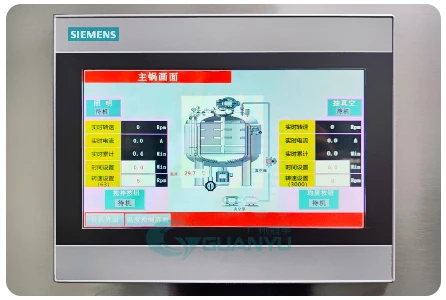

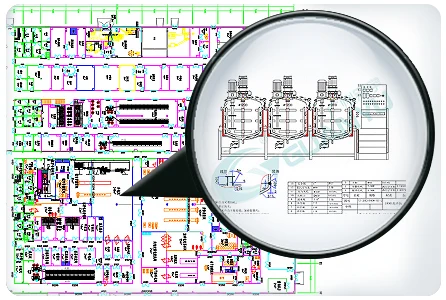

特征:1. The material of contacted part is SUS316L stainless steel, inside and outside of the equipment are with mirror polishing and get to GMP standard.2. All pipelines and parameter are controlled automaticlly. And the electric appliance which are imported from foreign country,like Siemens ,Schneider and so on.3. Emulsifying tank is with CIP cleaning system,it make the cleaning to be easy and effective.4.Emulsifying tank adopts tertiary agitating system, and during the emulsification ,the whole processing is under a vacuum environment, so it not only can eliminate spume which created in the emulsification processing ,but also can avoid the unnecessary pollution.5. The homogenizer adopts the most advanced technology,it can get a ideal emulsifying effect.The speed of high emulsification is 0-3600r/min, and the speed of low mixing is 0-63r/min.

模型 | 体积(L) | 混合力(千瓦) | 搅拌转速(转速) | 均质力(千瓦) | 均质转速(转速) | 加热方式 |

健身房-200 | 200 | 1.5 | 0〜63 | 4.0 | 0~3200 | 蒸汽加热或电加热 |

健身房-500 | 500 | 3.0 | 0〜63 | 7.5 | 0~3200 | |

健身房-1000 | 1000 | 4.0 | 0〜63 | 11 | 0~3200 | |

健身房-1500 | 1500 | 5.5 | 0〜63 | 11-15 | 0~3200 | |

健身房-2000 | 2000 | 7.5 | 0〜63 | 15-18.5 | 0~3200 | |

健身房-3000 | 3000 | 7.5-11 | 0〜63 | 18.5-22 | 0~3200 | |

健身房-5000 | 5000 | 11-15 | 0〜63 | 18.5-22 | 0~3200 |

搅拌桨

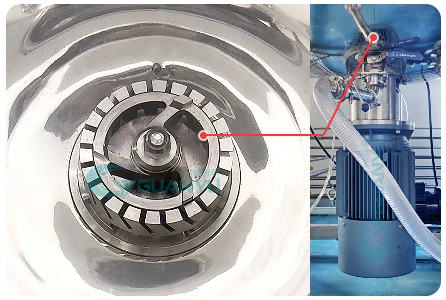

均质机

变频调速0-3200r/min, 均质剪切头高速剪切材料, 使物料完全破碎、混合!

◭全方位刮壁搅拌采用变频器调速 , 以便根据客户要求生产不同工艺的高品质产品.

真空泵

Plate and frame heat exchanger

Material hoist

气阀

安慰

服务

1..我们是谁?

评价

目前还没有评价