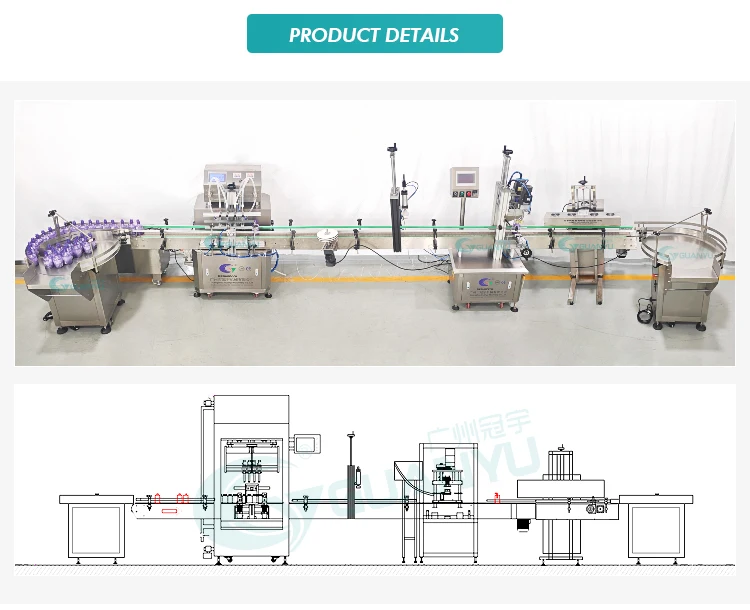

自动灌装生产线 化学品 液体化妆品 膏霜 沐浴露 洗发水 洗涤剂 液体 液体 膏体灌装

产品配置

服务 | 生产线所有设备均可根据客户要求定制 |

最大灌装速度 | 灌装200ml, 2000~3000 件/小时, 速度会因瓶子形状和颈部尺寸以及灌装材料成型和其他物理特性而不同 |

适用瓶径尺寸 | 30-300(毫米) |

适用瓶子高度尺寸 | 30-400(毫米) |

填充剂量 | 500 〜 5000 毫升(可定制) |

灌装精度 | ±1% |

电压 | 110电压~680V, 可以定制 |

把瓶子放好 | 理瓶机自动放瓶 |

工作压力 | 0.4 – 0.6兆帕 |

程序控制 | PLC+触摸屏人机界面 |

旋盖速度 | 2000-3000 瓶/小时 |

下盖方式 | 手动或振动盘 |

密封 | 如果需要,可以添加铝箔密封 |

主要特点(理瓶机):

1、适用于圆瓶、方瓶的自动分瓶和自动传送, 与塑料瓶和玻璃瓶兼容,

2、可连接贴标机传送带, 灌装机、旋盖机自动送瓶,提高效率;

3、可用于生产线末端自动收集瓶子

4、适用瓶子直径可自由调节, 与去皮瓶和塑料瓶兼容. 瓶子输送速度30~200瓶/分钟. 速度可无级调节, 方便生产安排.

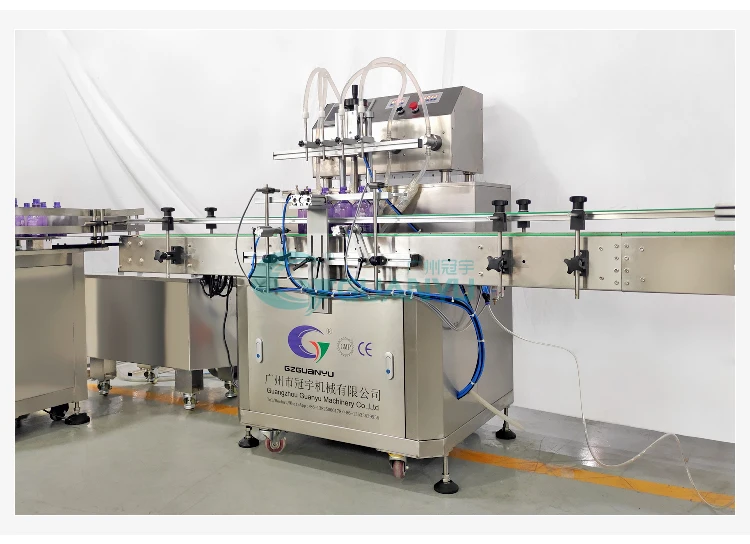

主要特点(灌装机):

1、设备兼容性强, 并能快速调节和更换不同形状、规格的瓶子,无需更换零件, 可以满足多种品种和规格的生产要求

2、PLC控制 ,触摸瓶操作 ,操作简单方便.

3、采用国际知名品牌电器元件, 性能和稳定性.

4、用户可调节灌装范围, 料斗内物料不足, 计算机将给送料泵信号

通过液位传感器添加材料. 当材料满了的时候, 泵将自动停止.

5、机身由 304 不锈钢, 易于清洁, 机器完全符合GMP要求.

6、蠕动泵或活塞泵灌装系统, 测量精度, 操控方便.

主要特点(旋盖机):

1、可根据瓶盖形状、瓶盖类型选配瓶盖提升机和振动给料机

2.、旋盖速度快, 可调自 0-45 瓶/分钟

3.、通过调整或更换一些配件,不同尺寸的瓶子和盖子可以共用一台机器

4.、旋盖时设备罐体不旋转, 从而避免了位移, 罐内产品的散落和可能的损坏.

5、适用于不同材质、不同规格的瓶盖.

6、采用三辊式旋盖刀 ,压力调节方便.

7、适用于金属盖 ,螺旋盖 , 防盗盖, 压缩帽, ETC…

主要特点(铝箔封口机):

1、铝箔封口机主要用于复合薄膜材料封口和聚烯烃塑料袋封口的加热封口 (例如聚乙烯, 聚丙烯, ETC。) 作为内层.

2、铝箔厚度和封口直径在一定范围内均可适用, 并能实现良好且均匀的线性密封.

3、无论大瓶, 小瓶, 长瓶或短瓶均可连续封口

4、机器所有加热部件均采用风冷强制冷却技术, 大大降低了制造成本,使设备小型化.

评价

目前还没有评价