物品 | 价值 |

健康)状况 | 新的 |

类型 | 灌装机 |

机械能力 | 其他, 2000前列腺肥大, 3000前列腺肥大 |

适用行业 | 食物 & 饮料厂, 化妆品厂 |

陈列室位置 | 泰国 |

应用 | 食物, 饮料, 化学, 化妆品 |

包装类型 | 瓶子, 其他 |

用于包装的材料 | 塑料, 玻璃, 其他 |

自动分级 | 自动的 |

驱动型 | 电的 |

电压 | 220电压/380V |

发源地 | 中国 |

粤 | |

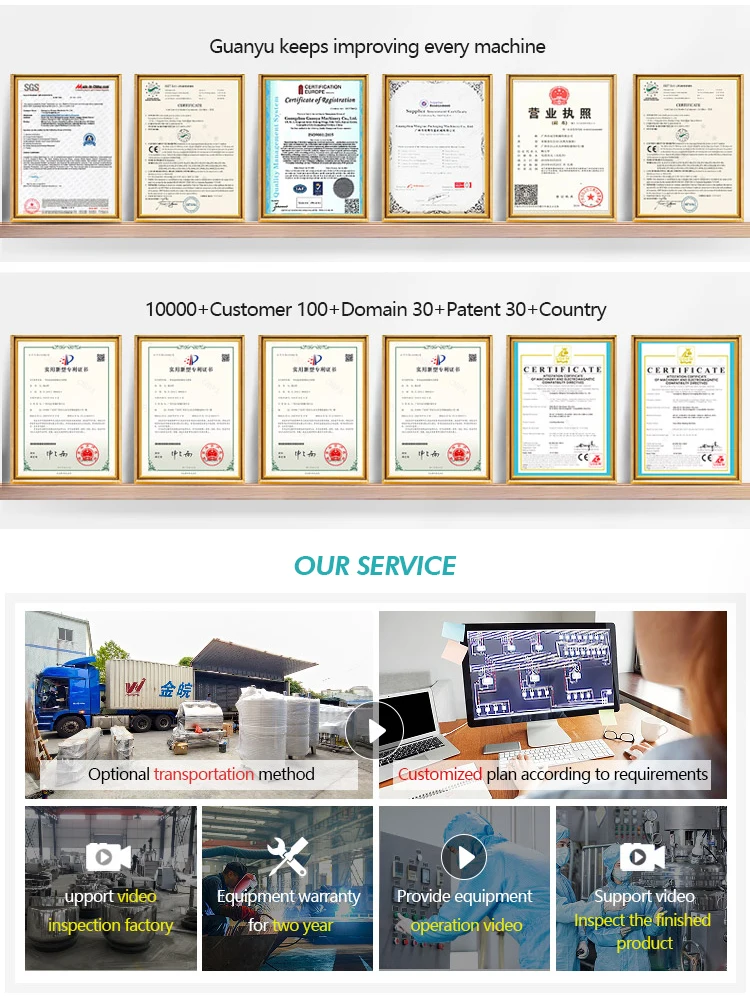

品牌 | Guanyu |

方面(长*宽*高) | |

重量 | 1200公斤 |

保修单 | 1 年 |

主要卖点 | 高生产率 |

填充材料 | 啤酒, 其他, 牛奶, 水, 油, 汁, 液体, 粘贴 |

灌装精度 | 99% |

机械测试报告 | 假如 |

视频出库检验 | 假如 |

核心部件保修 | 1 年 |

核心组件 | 压力容器, 泵, 其他, 可编程逻辑控制器 |

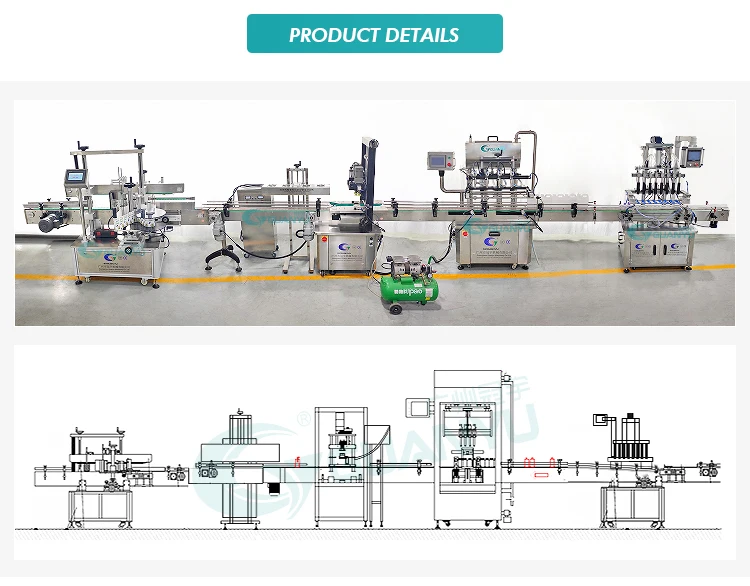

产品名称 | Filling Production Line |

功能 | Filling Capping Labeling |

用法 | 膏状 奶油酱 果酱 乳液 |

关键字 | Automatic Filling Line |

灌装速度 | 1000-3000前列腺肥大 |

材料 | 不锈钢 304/316 |

特征 | High Precision Filling Level |

填充范围 | 500-5000毫升(Customisable) |

控制 | PLC+触摸屏 |

灌装喷嘴 | 2/4/6/8/10/12(定制) |

Main Features(Negative ion dust removal machine):

1. Using precise double filtration, electrostatic ion generation ensures that no dust particles remain in the bottle.

2. Automatically store dust particles to ensure clean room air and operator health.

3. You can set the cleaning time according to your needs;

4. Use double (blow/inhale) mouthwash to remove dust from the bottle;

5. Use a precision filter (0.2一) to ensure the cleanliness of the air source;

6. It is suitable for assembly line operations, and can be matched with various assembly lines, with high efficiency

7. This machine can be used in beverage factories, food factories, chemical factories, cosmetics factories, pharmaceutical factories and other enterprises.

主要特点(灌装机):

1. 设备兼容性强, 并能快速调节和更换不同形状、规格的瓶子,无需更换零件, 可以满足多种品种和规格的生产要求

2. PLC控制 ,触摸瓶操作 ,操作简单方便.

3. 采用国际知名品牌电器元件, 性能和稳定性.

4. 用户可调节灌装范围, 料斗内物料不足, 计算机将给送料泵信号

通过液位传感器添加材料. 当材料满了的时候, 泵将自动停止.

5. 机身由 304 不锈钢, 易于清洁, 机器完全符合GMP要求.

6. 蠕动泵或活塞泵灌装系统, 测量精度, 操控方便.

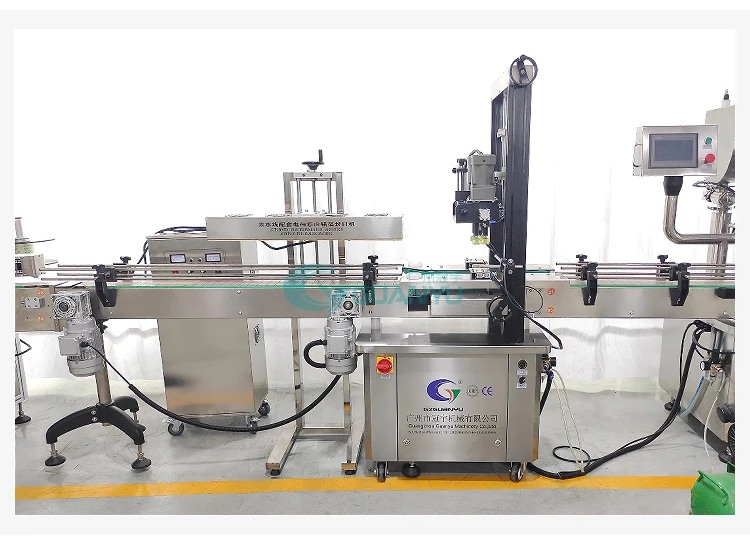

主要特点(旋盖机):

1. 可根据瓶盖形状、瓶盖类型选配瓶盖提升机和振动给料机

2. 旋盖速度快, 可调自 0-45 瓶/分钟

3. 通过调整或更换一些配件,不同尺寸的瓶子和盖子可以共用一台机器

4. 旋盖时设备罐体不旋转, 从而避免了位移, 罐内产品的散落和可能的损坏.

5. 适用于不同材质、不同规格的瓶盖.

6. 采用三辊式旋盖刀 ,压力调节方便.

7. 适用于金属盖 ,螺旋盖 , 防盗盖, 压缩帽, ETC…

Main Features(Labeling Machine):

1. Improve production efficiency, 20-60 件/分钟

2. The whole machine is made of S304 stainless steel and high-grade aluminum alloy, which meets the production requirements of GMP

3. Controlled by PLC man-machine interface, data can be saved, and the data can be directly called when changing the bottle

4. This machine has the mechanism of bottle guiding, bottle dividing, 标签, wheel leveling, counting and so on.

5. Wide range of application, labeling position, height and angle can be adjusted.

6. It can be connected to the conveyor belt to be used in the production line

评价

目前还没有评价