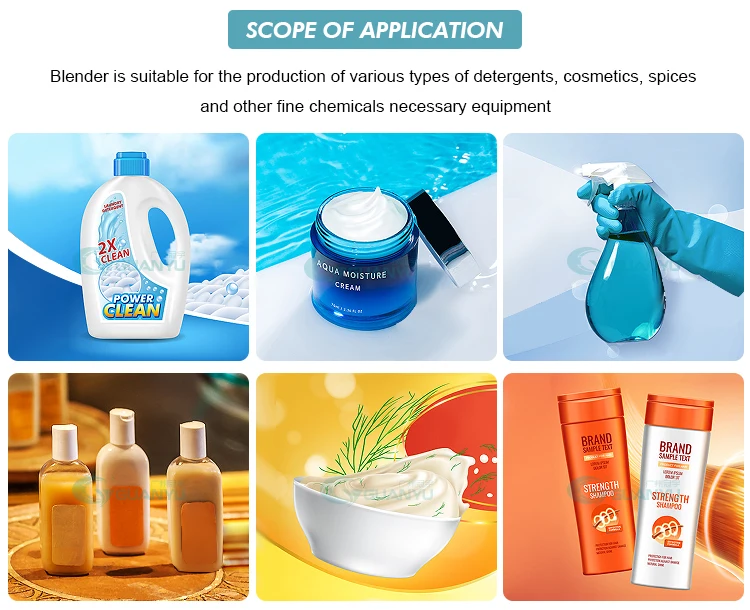

2000L 真空密封反应釜 搅拌罐 搅拌罐 番茄酱 大豆 面食 辣椒酱 蓝莓果酱 橄榄油 人造黄油

产品描述

产品规格

模型 | 体积(L) | 混合功率(kw) | 混合旋转速度(r/m) | 匀浆能力(千瓦) | 同质速度(转速) | 加热方法 |

GY-200 | 200 | 1.5 | 0〜63 | 4.0 | 0~3200 | steam heating or electirc heating |

GY-500 | 500 | 3.0 | 0〜63 | 7.5 | 0~3200 | |

GY-1000 | 1000 | 4.0 | 0〜63 | 11 | 0~3200 | |

GY-1500 | 1500 | 5.5 | 0〜63 | 11-15 | 0~3200 | |

GY-2000 | 2000 | 7.5 | 0〜63 | 15-15.8 | 0~3200 | |

GY-3000 | 3000 | 7.5-11 | 0〜63 | 18.5-22 | 0~3200 | |

GY-5000 | 5000 | 11 | 0〜63 | 18.5-22 | 0~3200 |

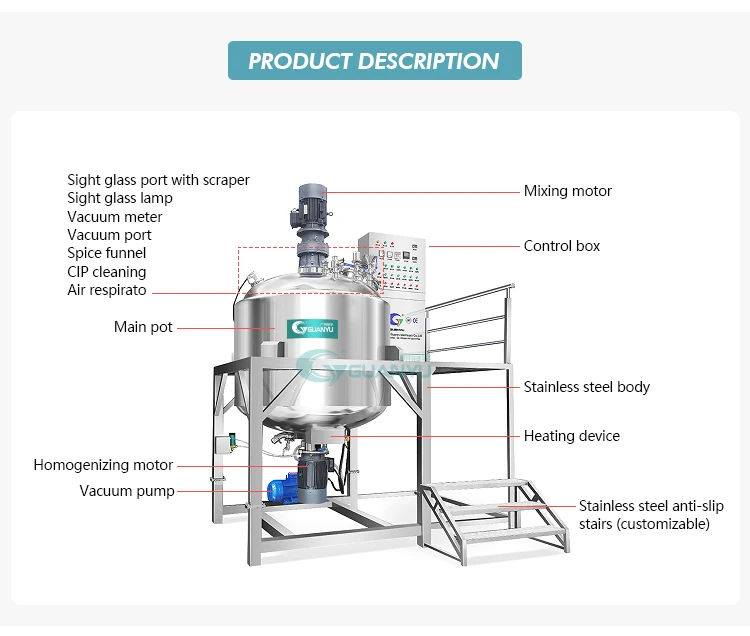

表演和功能

◭全方位刮壁搅拌采用变频器调速 , so that high

quality products of different processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindis

soluble materials such as AES , AESA , LSA , ETC. during the liquid detergent production process so as to save energy consumpion

and shorten production period.

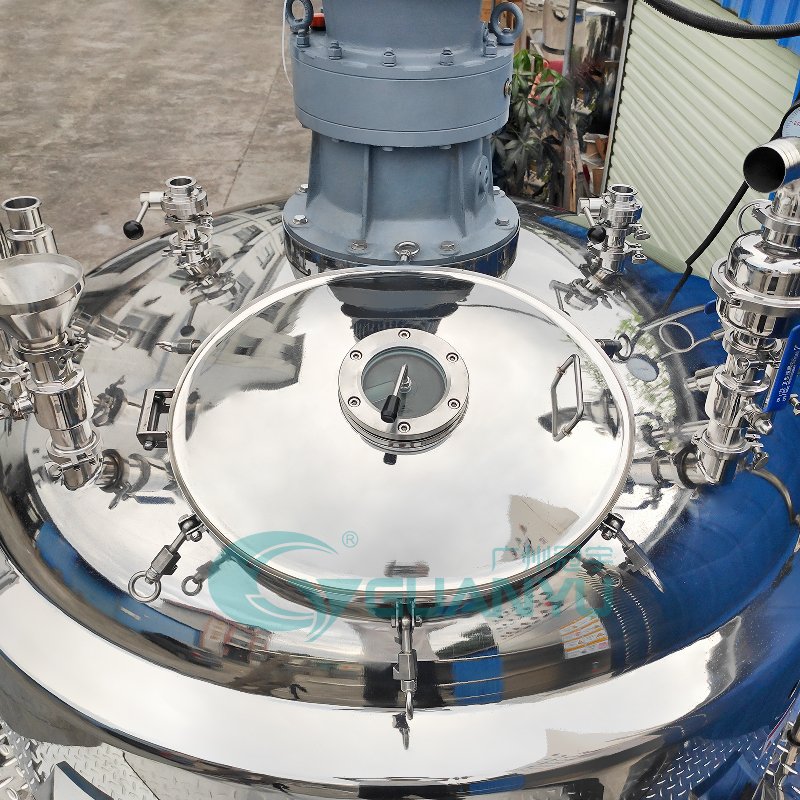

pot锅由进口的三层不锈钢板焊接. 罐体及管道采用米特抛光 , 哪个

fully conforms to GMP requirements.

◭根据客户要求 , 罐体可加热和冷却物料. The heating way including steam heating and electric

加热. 易于放电 , 底部直接排放或通过输送泵排放.

更多细节

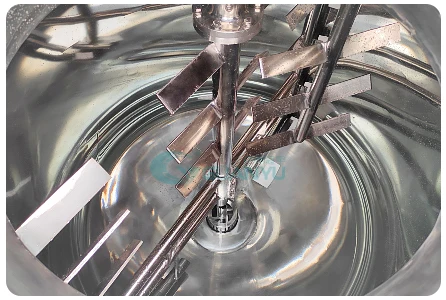

搅拌桨

变频调速0-62r/min, 使不同的材料能够混合均匀. 搅拌桨的形状将根据您的物料设计

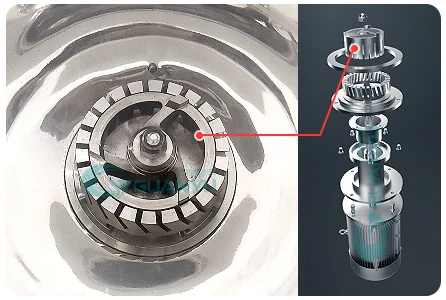

均质机

变频调速0-3200r/min, 均质剪切头高速剪切材料, 使物料完全破碎、混合!

真空泵

真空环境下, 物料混合时乳化锅可排出泡沫, 从而提高待处理材料的质量. 真空脱泡工艺,保证物料无菌

释放

锅的圆底旨在使底部放电清洁剂并减少材料的残留物

(如有必要, 可以配备排放泵直接提取材料)

(如有必要, 可以配备排放泵直接提取材料)

安慰

控制箱包括均匀剪切等设置, 变频调速搅拌,

工作时间, 真空抽气, 层间加热, ETC.

(PLC控制是可选的)

工作时间, 真空抽气, 层间加热, ETC.

(PLC控制是可选的)

服务

采用国际知名品牌零部件,保证设备质量和更长的使用寿命

欢迎与Guanyu联系并获得!

评价

目前还没有评价