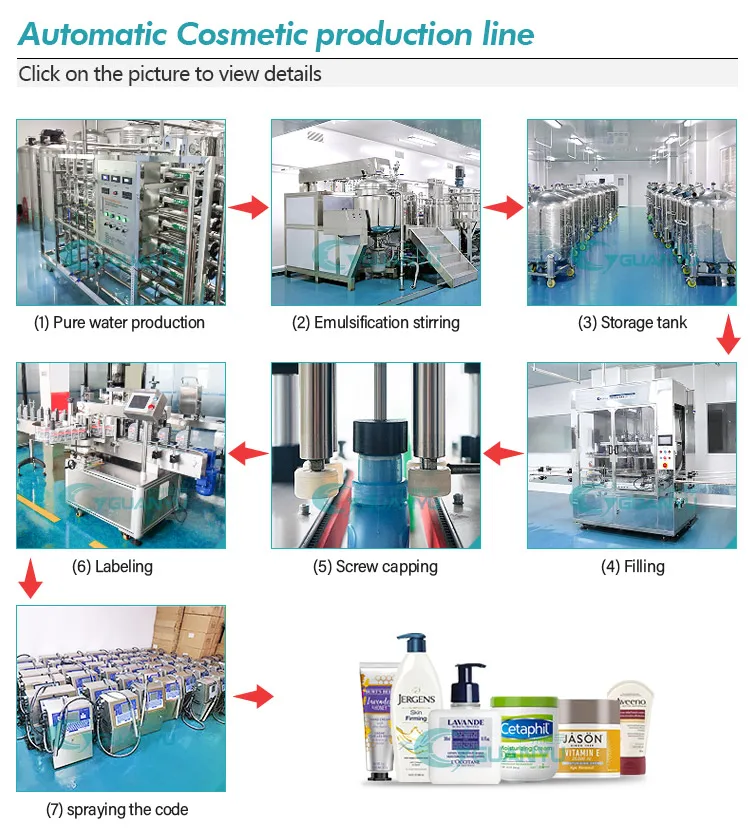

2000L Vacuum Homogenizing double jacket Stainless Steel High-speed Shearing Mixing Emulsifying Tank Machine cosmetic cream

产品描述

模型 | 体积(L) | Blending power(kw) | Blending rotation speed(r/m) | homogenizing power(千瓦) | homogeniziing speed(转速) | heating method |

GY-200 | 200 | 1.5 | 0〜63 | 4.0 | 0~3200 | steam heating or electirc heating |

GY-500 | 500 | 3.0 | 0〜63 | 7.5 | 0~3200 | |

GY-1000 | 1000 | 4.0 | 0〜63 | 11 | 0~3200 | |

GY-1500 | 1500 | 5.5 | 0〜63 | 11-15 | 0~3200 | |

GY-2000 | 2000 | 7.5 | 0〜63 | 15-15.8 | 0~3200 | |

GY-3000 | 3000 | 7.5-11 | 0〜63 | 18.5-22 | 0~3200 | |

GY-5000 | 5000 | 11 | 0〜63 | 18.5-22 | 0~3200 |

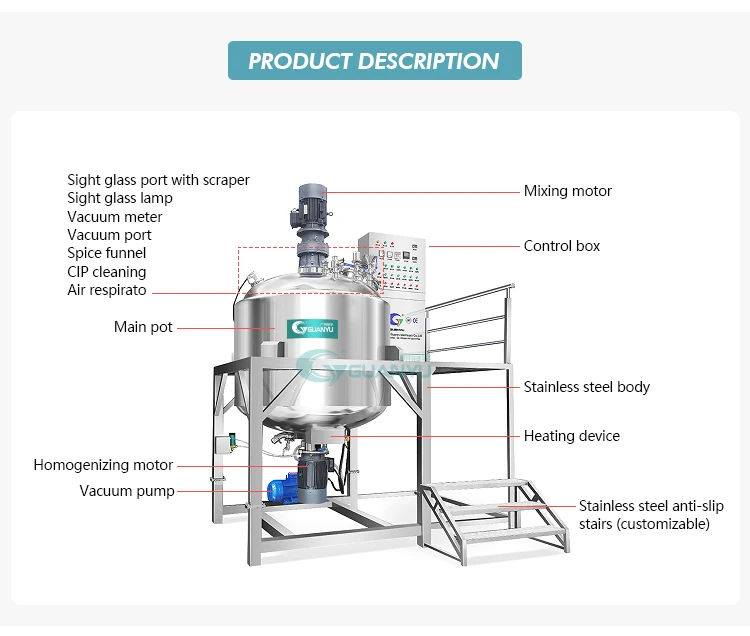

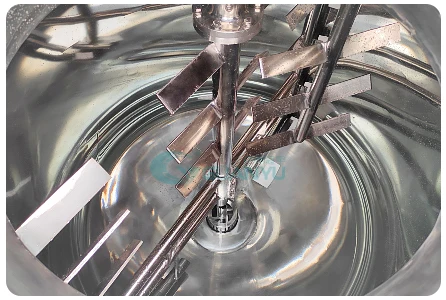

搅拌桨

变频调速0-62r/min, 使不同的材料能够混合均匀. 搅拌桨的形状将根据您的物料设计

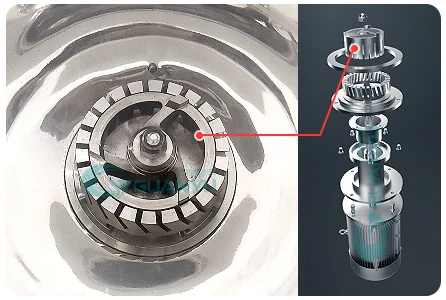

均质机

变频调速0-3200r/min, 均质剪切头高速剪切材料, 使物料完全破碎、混合!

真空泵

真空环境下, 物料混合时乳化锅可排出泡沫, 从而提高待处理材料的质量. 真空脱泡工艺,保证物料无菌

Discharge

The round bottom of the pot is designed to make the bottom discharge cleaner and reduce the residue of materials

(if necessary, a discharge pump can be equipped to directly extract materials)

(if necessary, a discharge pump can be equipped to directly extract materials)

安慰

控制箱包括均匀剪切等设置, 变频调速搅拌,

工作时间, 真空抽气, 层间加热, ETC.

(PLC control is optional)

工作时间, 真空抽气, 层间加热, ETC.

(PLC control is optional)

服务

采用国际知名品牌零部件,保证设备质量和更长的使用寿命

评价

目前还没有评价