Businesses that make makeup or skincare products get the most help from cosmetic production equipment automation. 今天, factories need to work fast, make good products, and grow quickly. 广州冠宇机械有限公司等公司, 有限公司. 使用新技术, like the Vacuum Emulsifying Mixer, to help brands meet what the industry wants.

方面 | Impact on Manufacturing |

|---|---|

Automation makes things faster and cuts down on waiting. | |

Equipment gives the same results and fewer mistakes. | |

可伸缩性 | Systems can handle small or big groups of makeup. |

关键要点

Automation makes cosmetic production faster and keeps quality the same. This helps businesses make more products quickly with fewer errors. Using automated machines saves work by cutting down on manual jobs. Workers can do other important things and stay safer. Automation lets companies grow by adding or upgrading machines. This helps meet higher demand without slowing down. Starting automation costs a lot and needs skilled workers for upkeep. Businesses should plan their money and training well. Picking automation depends on your business size and product types. It also depends on your budget and how you want to grow. This helps you find what works best for your needs.

Benefits of Cosmetic Production Equipment

提高效率

Cosmetic production equipment helps factories work faster. Automation makes each step, 喜欢 mixing and filling, go quickly. Machines such as the 真空乳化搅拌机 from Guangzhou Guanyu Machinery Co., 有限公司. mix things faster. This lets factories make more products in less time. 这 V5 Traceability system helps by planning and tracking batches. This keeps everything moving fast. Some companies clean their machines 63% 快点 现在. This means they spend less time waiting and more time making products. Automation and robotics help the work stay smooth and quick.

一致的质量

Automation helps every batch of makeup or skincare turn out the same. Automated systems use sensors to check fill levels. This stops mistakes like overfilling or mixing in germs. It makes the products better and wastes less. The Vacuum Emulsifying Mixer uses vacuum technology to mix things evenly. Creams and lotions always feel right. Automation also helps companies follow rules and keep products safe for people.

Labor Savings

Automation means workers do not have to do as much by hand. Machines mix, 充满, 并包装产品. Workers can do other jobs instead. This lowers mistakes and keeps people safer at work. 例如, a makeup brush cleaning machine or an ultrasonic makeup brush cleaning system cleans brushes faster than people can. These machines save time and help companies use their workers better.

可伸缩性

Automated cosmetic production equipment helps businesses grow easily. When more people want makeup, companies can add more machines or upgrade them. This does not slow down the work. 这 table below shows how automation helps companies get bigger:

公司 | Solution Used | 可伸缩性 & Efficiency Benefits |

|---|---|---|

Symrise | Vertical Lift Modules (VLMs) | Managed 40,000 瓶子, saved space, protected sensitive products. |

Bios Line | Vertical Lift Modules (VLMs) | Improved order fulfillment and productivity. |

Solimè | Three VLMs | Faster order processing, better e-commerce operations. |

Automation helps companies track products and control inventory. It also helps them face new problems. Companies can use less energy and make less waste. Technology and robotics make factories ready for the future and help them change when needed.

Drawbacks of Automation

High Investment

Automation in cosmetics needs a lot of money at first. Companies have to buy expensive machines like mixers and filling lines. These machines cost more than doing things by hand. Many businesses also need to change their buildings for the new machines. This makes starting costs high for small or new companies. Automation can save money later, but it costs a lot to begin.

维护需求

Automated systems need special care to work well.

Skilled workers must do hard jobs like checking sensors and fixing parts.

It costs more to take care of automated machines than simple ones.

Staff need training to use automated bottle filling lines.

Manual systems use easy tools and cost less to fix.

Companies must plan for these extra costs and make sure they have trained workers.

Job Impact

Automation changes how people work in factories. Some jobs now need workers with special skills.

Many companies teach their teams new skills for automation jobs.

Studies say 66% of leaders think retraining is very important.

More than half of bosses plan to retrain or replace some workers soon.

Companies spend money on training so workers can learn new things.

Retraining helps keep workers and supports company goals, but it is hard to know what skills will be needed later.

Flexibility Limits

Automation works best for big groups of the same product. It is harder to make special products with automated machines. 在化妆品中, making unique items often needs people to help and check the work. Automation makes it tough to change formulas or packaging for each customer. Companies that want to offer many choices may find automation less helpful.

Quality in Manufacturing Automation

Product Consistency

Automation helps make sure each batch is the same. Companies use machines so creams and lotions always look and feel alike. Oully uses robots to lower labor costs and mistakes. This means there are fewer errors and better products.

Machines check for problems early.

Computers can find issues before they get worse.

Live monitoring catches bad products quickly.

All parts of production, inventory, and shipping work together.

Machine learning finds equipment problems to improve quality.

Automated systems collect batch data without people typing it in. This cuts down on mistakes. If there is a problem, the system warns right away. Leaders can see what is happening on screens in real time. Quality checks are built into the process, so nothing moves forward without a check. Rules and steps stay the same with digital tools. These actions help companies keep every batch high quality.

卫生与安全

Automation keeps products and workers safe. Machines that touch raw materials use safe, strong materials. Smooth inside walls make cleaning simple. Sealed pipes and machines help keep things clean.

Air, 温度, and humidity are controlled for safety.

Work areas are kept apart to stop mixing.

Workers must follow hygiene rules, like health checks and hand washing.

Automation lowers the chance of germs by reducing human touch. Machines clean themselves without being taken apart. This stops germs from coming back. Some systems use special cleaning, like vapor or UV light, to kill germs. These methods clean the same way every time. Automation makes factories safer for people and products.

Compliance and Standards

Automation helps companies follow tough industry rules. Many machine makers, 比如广州冠宇机械有限公司。, 有限公司, have ISO9001 certification. This means they follow world quality rules. Some also have CE and UL certifications for safety in other countries.

Quality control is very important in automated factories. Companies use live quality checks and records to track everything. Good reports help find and fix problems. These systems help companies get better and follow all the rules. Smart factories use automation to make sure every product is high quality.

Is Automation Right for Your Business?

Business Size

How big your business is matters a lot when picking automation. Small companies that make fewer products often use manual or semi-automatic machines. These ways are good if you need to change things quickly. When a company starts making more products, automated systems help more. Big companies with lots to make usually pick full automation. This saves them time and money.

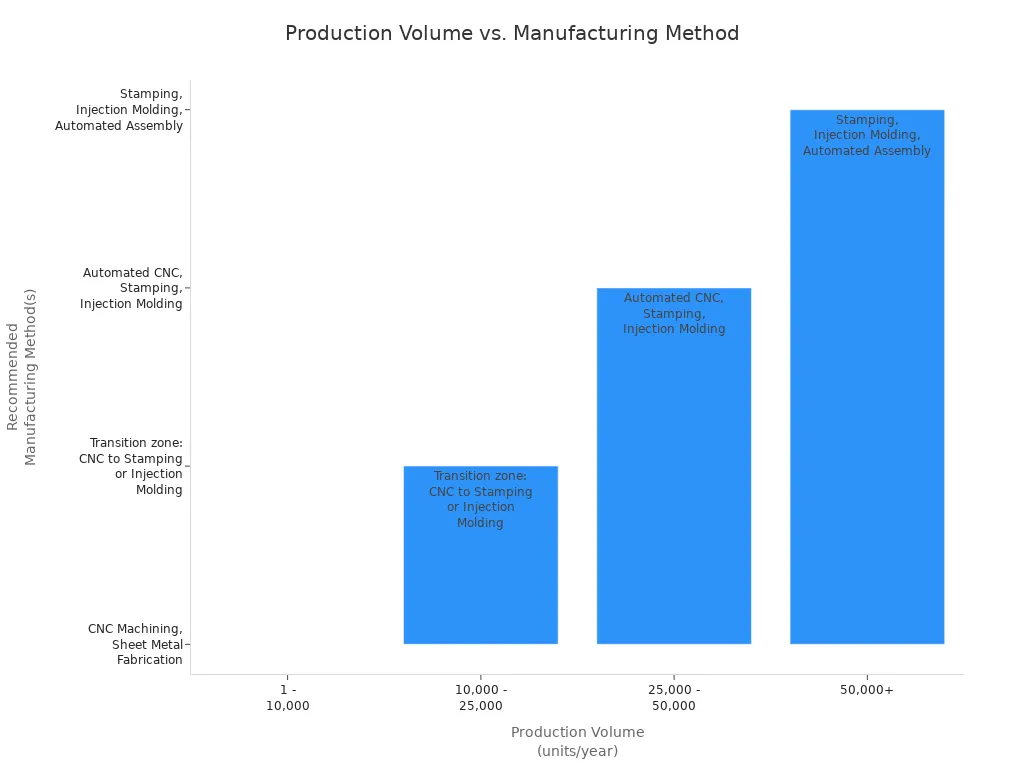

Recommended Manufacturing Method(s) | Justification / 笔记 | |

|---|---|---|

1 – 10,000 | CNC Machining, Sheet Metal Fabrication | Low-volume methods are best for being flexible and trying new designs. They also cost less to start. |

10,000 – 25,000 | Transition zone: CNC to Stamping or Injection Molding | The best choice depends on how hard the part is to make and the cost of tools. Stamping is cheaper if you make more than about 15,000-20,000 部分. Injection molding is a good deal if you make more than about 10,000-15,000 部分. |

25,000 – 50,000 | Automated CNC (if complexity justifies), Stamping, Injection Molding | Automated CNC works well up to about 25,000 部分. 在那之后, stamping or molding is better because it costs less for each part and uses materials better. |

50,000+ | Stamping, Injection Molding, Automated Assembly | High-volume ways are worth it because you save money when making a lot, even though tools cost $8,000 到 $50,000 或更多. |

提示: Companies should check how many products they make each year. Automation is usually a good idea if you make more than 25,000 units a year.

预算

How much money you have changes what automation you can get. Equipment prices depend on how much automation you want and what kind of machines you need. Machines for making cosmetics can cost from $10,000 到 $100,000. Packaging machines cost between $3,000 和 $30,000. More automation costs more, but it also makes things faster and needs less work from people.

The amount of automation changes how much you can make and how much it costs.

Automatic machines are best for making lots of products and usually cost the most.

Semi-automatic and manual machines are cheaper but make fewer products at a time.

What you pick depends on your money and how much you need to make.

笔记: Companies should think about both the starting price and the money they will save later with automation. Talking to machine sellers can help you find the best fit for your budget.

产品范围

How many different products you make changes how well automation works. If you make lots of different things, like many foundation shades or creams, automation can be harder. Automated systems work best when you make big batches of the same thing. If customers want lots of choices, you might still need people to help.

Having many types of cosmetic products means customers want special care. Automation may not always give the personal touch needed for different skin colors, 纹理, and likes.

People often mix foundation shades and textures to get what they want. This is hard for machines to do without help from people.

Brands like Fenty and The Ordinary now offer many more product choices. 例如, Fenty has 40 foundation shades. This shows how important it is to have options for everyone.

一个 2021 Mintel report says 72% of Americans think beauty standards are too strict. 还, 68% want to see more diversity in beauty ads. This means people want more choices in products.

Picking beauty products is very personal. Good customer service needs to be flexible and caring. Simple automation cannot always do this as well as people can.

Companies with only a few products can use automation more easily. If you have lots of products, you may need both machines and people.

Growth Plans

Thinking about growing helps you decide if automation is smart. If your company wants to get bigger, you should think about what you will need later. Automation helps you make more products fast. It also helps keep quality high as you grow. If you want to make new products or sell in new places, flexible machines can help.

Companies should ask themselves:

Will we make more products soon?

Are we planning new products or lines?

Do we need to get faster or better?

Talking to machine sellers like Guangzhou Guanyu Machinery Co., 有限公司. gives you expert help. They can suggest machines that work now and as you grow.

Checklist for Decision-Making:

Check how much you make now and what you expect to make later.

Make a clear plan for how much money you can spend on machines and upgrades.

List all your products and see if machines can handle them.

Think about how you want to grow and change your business.

Looking at these things carefully helps you pick the right amount of automation. The best choice helps you make products well, 保持高质量, and grow your business—whether you make makeup brushes, 面霜, or other cosmetic products.

Automation helps cosmetic companies make products faster. It keeps the quality the same every time. Automation makes it easier for companies to grow. Some companies spend a lot of money on automation. They also cannot change things as easily. Small brands might wait before using automation. Big companies often need automation to stay ahead. Automation lets workers do their jobs better and safer. Many bosses use automation to follow rules and keep products safe. Automation helps keep things clean and stops mistakes. It also helps companies get ready for the future. Automation lets brands get bigger and do better. Getting help from experts makes automation work best. Guangzhou Guanyu Machinery Co., 有限公司. can help companies use automation well.

常问问题

What products can automated cosmetic equipment make?

Automated machines can make creams, 乳液, 血清, 凝胶, 和药膏. Many machines, 喜欢 真空乳化搅拌机, work with lots of cosmetic and skincare products. Some systems also help make daily chemicals and medicines.

How does automation improve product safety?

Automation keeps people from touching ingredients too much. Machines use closed systems and smooth, clean surfaces. This helps stop germs from getting in. Many automated lines have cleaning parts and sensors that check for safety at every step.

Is it hard to switch recipes with automated machines?

How easy it is to switch recipes depends on the machine. Some equipment, like those from Guangzhou Guanyu Machinery Co., 有限公司, lets you change recipes with digital controls. Operators can pick new settings fast for different products.

What support do manufacturers offer after buying equipment?

Manufacturers like Guangzhou Guanyu Machinery Co., 有限公司. help with setup, 训练, 和固定机. They send engineers to help and give service for as long as you own the machine. Customers can get help with problems and upgrades.

Can small businesses use automated cosmetic equipment?

Small businesses can use semi-automatic or small machines. These choices cost less and fit in small places. Automation helps small brands grow by making things faster and better without needing a big team.

Citibet88, check it. Easy to get around the site. Odds seemed decent. I’d recommend doing your homework as always, but worth a look see. Take a look: citibet88

MQMBet? Never heard of it before, to be honest. Might be a newer platform. Always be careful with new sites, and make sure they’re properly licensed before you start betting. You can find their site at mqmbet. Proceed with caution!

能不能具体说一下你文章的内容? 读完后, 我还是有一些疑问. 希望你能帮助我.