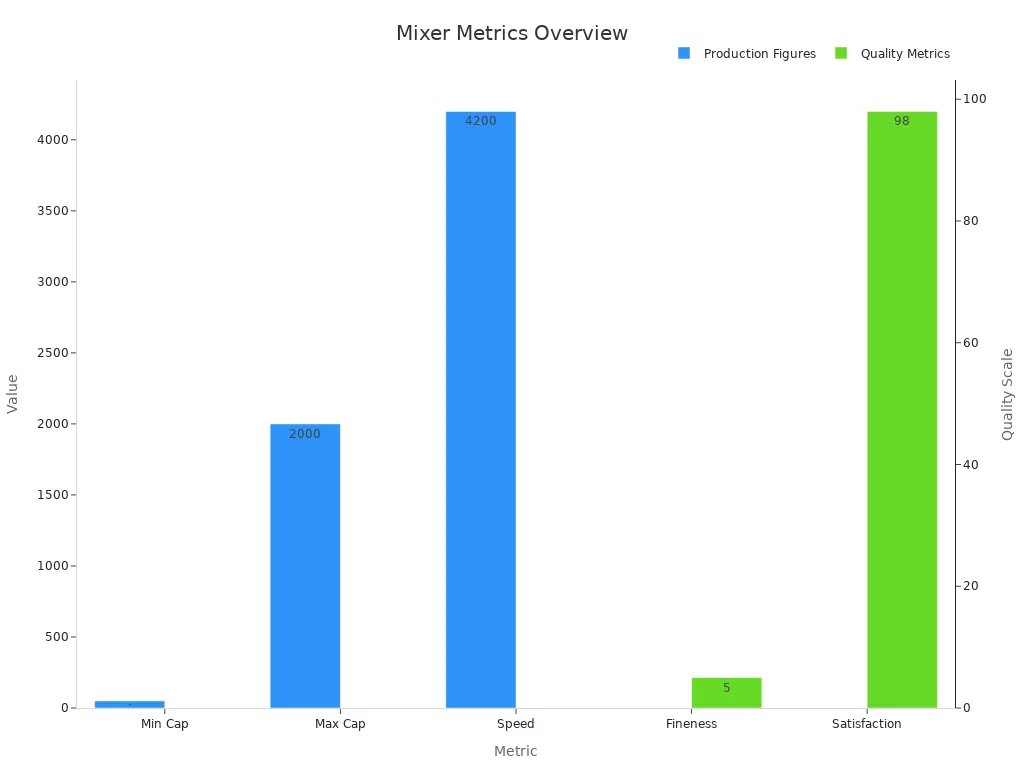

Vacuum emulsifying mixers give cosmetics and sunscreen manufacturers clear advantages in product quality, process speed, 和安全. Guangzhou Guanyu, a trusted leader in advanced mixing technology, offers a Vacuum Emulsifying Mixer that meets strict industry standards. These machines operate at speeds up to 4200 RPM, achieve shearing fineness down to 5 微米, and support batch capacities from 50L to 2000L. High consumer satisfaction and ISO9001 certification show the reliability of this technology.

关键要点

真空乳化搅拌机 create smooth, bubble-free cosmetics and sunscreens with better texture and longer shelf life.

These mixers speed up production by combining mixing, 加热, and vacuuming in one efficient process.

Automatic cleaning systems and stainless steel parts make maintenance easy and keep products safe from contamination.

The closed vacuum system removes air, preventing oxidation and improving product stability and appearance.

Manufacturers benefit from consistent quality, 降低成本, and flexible customization to meet different production needs.

概述

What Are They

Vacuum emulsifying mixers are advanced machines designed to 混合, 乳化, and homogenize ingredients under vacuum conditions. These mixers play a vital role in producing cosmetics and sunscreen, where smooth texture and product stability matter most. By removing air from the mixing chamber, they prevent bubbles and oxidation, which helps maintain the purity and shelf life of creams and lotions.

Guangzhou Guanyu stands out as a leading manufacturer in this field. 随着超过 35 多年经验, the company offers a range of vacuum emulsifying mixers that meet strict hygiene and safety standards. Their machines use food-grade stainless steel and mirror polishing for durability and easy cleaning. The mixers support a wide range of applications, from cosmetics and pharmaceuticals to food and fine chemicals.

笔记: Vacuum emulsifying mixers from Guangzhou Guanyu feature automated lid-lifting, vacuum-based ingredient transfer, 和精确的温度控制. These features improve efficiency and ensure consistent results.

它们是如何工作的

Vacuum emulsifying mixers combine several functions in one system. The process starts with the vacuum system, which removes air and allows for powder suction. 下一个, the mixer uses 高剪切均质机 and paddles to blend ingredients. The machine can heat or cool the mixture as needed, protecting sensitive ingredients from damage.

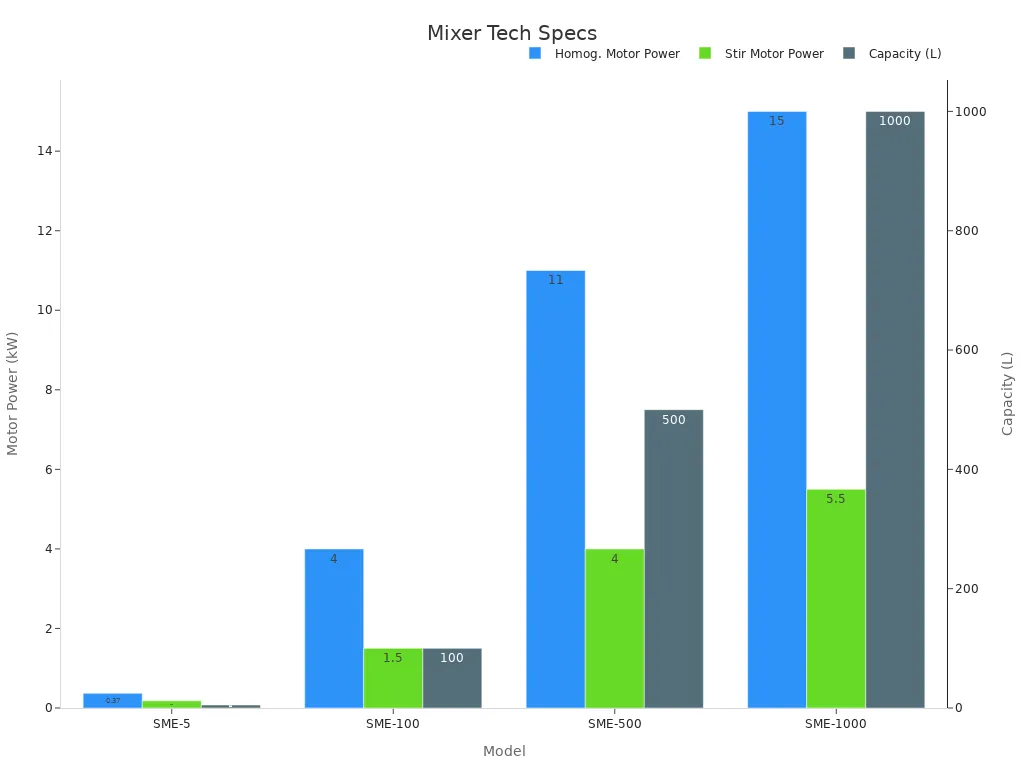

The following table highlights key technical features:

模型 | 工作量 (L) | 加热方式 | 混合速度 (RPM) | 同质速度 (RPM) |

|---|---|---|---|---|

JT-VEM-50L | 50 | Electric or Steam Heating | 0-63 | 0-3000 |

JT-VEM-200L | 200 | Electric or Steam Heating | 0-63 | 0-3000 |

JT-VEM-1000L | 1000 | Electric or Steam Heating | 0-63 | 0-3000 |

Specialized impeller designs and variable speed controls allow for precise mixing and particle size reduction. The mixers can achieve particle sizes as small as a few microns, which improves product texture and stability. Automation and smart controls help manage recipes and ensure repeatable quality.

Vacuum emulsifying mixers support clean-label and natural ingredient formulations. Their energy-efficient designs and compliance with eco-friendly standards make them a reliable choice for modern manufacturers.

产品质量

Homogeneity and Texture

真空乳化搅拌机 create creams and sunscreens with a smooth, even texture. These machines use high-shear mixing and precise temperature control to blend ingredients thoroughly. Manufacturers often choose them for products that need a fine, luxurious feel. A study compared emulsions made with a planetary mixer at normal pressure and under vacuum. The vacuum process produced creams with smaller, more uniform oil droplets. This led to better stability and a softer texture. In real-world production, companies report that vacuum systems help remove clumps and ensure every batch looks and feels the same. This level of homogeneity is important for both consumer satisfaction and brand reputation.

笔记: Uniform droplet size and smooth texture help creams spread easily on the skin, making them more pleasant to use.

Air Bubble Elimination

Air bubbles can ruin the appearance and performance of cosmetics and sunscreens. Vacuum emulsifying mixers solve this problem by removing air during the mixing process. The vacuum system pulls out trapped air, which prevents bubbles from forming in the final product. This step is especially important for high-viscosity materials, such as thick creams and gels. Sensitive ingredients also benefit because less air means less oxidation and longer-lasting freshness. The result is a product that looks clear and professional, with no unwanted pockets of air.

No air bubbles means:

Smoother application

Better product stability

Improved packaging appearance

Stability and Shelf Life

Product stability matters in cosmetics and sunscreen manufacturing. Vacuum emulsifying mixers help keep formulas stable by creating a tight emulsion. The even distribution of oil and water phases prevents separation over time. This process also protects sensitive ingredients from air and light, which can cause spoilage. Manufacturers see longer shelf life and fewer product returns when using this technology. Consistent mixing ensures that preservatives and active ingredients work as intended, giving customers safe and effective products.

提示: Stable creams and sunscreens reduce waste and support a positive brand image.

Process Efficiency

Faster Production

Manufacturers value speed in cosmetics and sunscreen production. 真空乳化搅拌机 deliver rapid results by combining multiple steps into one streamlined process. Operators can produce a 2% Xanthan Gum solution in just 10 分钟. The machine allows quick changes of workheads, so teams can switch between mixing tasks without extra equipment. High shear mixing technology ensures agglomerate-free blends and stable emulsions, which reduces batch processing time and minimizes downtime. The elimination of air and heat during emulsifying phases further optimizes both quality and speed. These features help companies meet tight deadlines and increase output.

Key time-saving benefits:

Fast mixing cycles

Quick workhead changes

Reduced downtime between batches

易于清洁

Hygiene and efficiency go hand in hand. Vacuum emulsifying mixers from Guangzhou Guanyu include an automatic Clean-In-Place (CIP) 系统. This system cleans the machine without manual disassembly, saving time and preventing contamination. Removable vessels and cover lifting mechanisms provide easy access for thorough cleaning. All product contact parts use stainless steel 316L with a mirror polish, which enhances cleanability. The control panel displays time and temperature, making operation straightforward. The vacuum environment also reduces contamination and oxidation risks, supporting a cleaner process.

Cleaning advantages:

CIP system reaches hard-to-clean areas

Stainless steel and mirror polish for easy maintenance

Hopper cover lifts electrically or mechanically for better access

一致性

Consistency defines product quality and brand trust. Vacuum emulsifying mixers ensure every batch meets the same high standards. The machine’s design allows mixing, 乳化, 匀浆, 吸尘, 加热, 和冷却 in one unit. This integration simplifies operation and reduces the chance of errors. Safety features like PLC control panels and emergency stop buttons make the process user-friendly. Guanyu’s after-sales support, including detailed manuals and global technical assistance, helps operators maintain reliable performance. Manufacturers can expect uniform results, batch after batch.

提示: Consistent production supports customer satisfaction and reduces product returns.

Packaging and Safety

No Air Bubbles

Vacuum emulsifying mixers remove air from the product during mixing. This process prevents air bubbles from forming in creams and sunscreens. Air bubbles can cause problems in 包装. They may lead to uneven filling, 泄漏, or even spoilage. By eliminating these bubbles, manufacturers achieve a smooth and uniform product. This step also helps the product fill containers more evenly, which improves the final appearance and reduces waste.

A bubble-free product not only looks better but also performs better. Customers notice the difference when they use a cream that spreads smoothly and feels consistent.

Contamination Prevention

Contamination control is a top priority 在 cosmetics and sunscreen production. Vacuum emulsifying mixers support this goal by creating a closed, controlled environment. The vacuum system removes air, which limits the chance for microorganisms or particles to enter the product. Stainless steel construction and automated cleaning systems further reduce contamination risks. These features align with industry standards for quality assurance and safety.

Quality assurance frameworks, such as Quality by Design (QbD), highlight the importance of controlling mixing speed, 时间, 和同质化. Vacuum emulsifying mixers help maintain these critical parameters. This control ensures uniform dispersion and reduces the risk of contamination. Manufacturers can trust that each batch meets strict safety and quality standards.

Appearance

Product appearance matters in the cosmetics and sunscreen market. Consumers expect creams and lotions to look smooth, glossy, and free of defects. Vacuum emulsifying mixers help achieve this by producing fine, stable emulsions without visible air pockets or separation. The result is a product that looks appealing on store shelves and in the hands of customers.

Benefits for appearance:

光滑的, glossy finish

No visible bubbles or streaks

Consistent color and texture

A high-quality appearance builds trust and encourages repeat purchases. Manufacturers who use vacuum emulsifying mixers can deliver products that meet both safety and aesthetic expectations.

Vacuum Emulsifying Mixers vs. Traditional Methods

关键差异

真空乳化搅拌机 stand apart from traditional mixing methods in several important ways. These advanced machines use vacuum technology to remove air from the mixing chamber. This step prevents air bubbles and contamination, which often affect product quality in standard mixers. High-speed homogenizers with adjustable speeds allow operators to tailor the process for each formulation. The mixers use SUS316L stainless steel and mirror-polished surfaces to meet strict hygiene and GMP standards.

Vacuum conditions reduce air and contamination, improving shelf life.

High-speed homogenizers create finer, more stable emulsions.

Advanced cleaning systems, such as hydraulic lift lids and CIP, make maintenance easier.

The closed design prevents powder contamination and bubble formation.

Automation and smart controls ensure stable production and reduce manual errors.

These mixers require less floor space and support higher efficiency.

Traditional mixers often lack these features. They may allow air to enter the product, leading to bubbles and faster spoilage. Cleaning and maintenance take longer, and the process may not meet modern hygiene standards.

Unique Benefits

Vacuum emulsifying mixers deliver unique advantages that go beyond basic mixing. The following table highlights key performance metrics and cost-benefit factors:

性能指标 / Cost-Benefit Factor | 描述 | Impact on Cosmetic Production |

|---|---|---|

High-shear capability | Produces fine emulsions and consistent textures | Ensures product quality and uniformity |

Adjustable speed settings | Allows process flexibility tailored to formulations | Enhances product quality and reduces processing time |

Vacuum function | Minimizes air incorporation and improves powder dispersion | Achieves smooth, 稳定的乳液, critical for sensitive ingredients |

Compliance with hygiene and industry standards | Reduces contamination risks | Ensures safety and regulatory adherence |

Operational efficiency improvement | Boosts production throughput and reduces costs | |

Durable materials (不锈钢, alloys) | Resist corrosion and wear | Extends equipment lifespan and reliability |

Reduced labor costs | Automation and ease of use lower manual intervention | Lowers operational expenses |

Lower energy consumption | Efficient design reduces power usage | Decreases utility costs and environmental impact |

Minimized waste | Precise mixing reduces raw material loss | Improves cost-effectiveness and sustainability |

Easy maintenance and fewer repairs | Design facilitates quick cleaning and durable parts | Minimizes downtime and repair expenses |

Scalability and versatility | Handles various formulations and production scales | Supports growth and diverse product lines |

Manufacturers benefit from faster processing, more stable emulsions, and lower costs. Automation and smart controls help maintain uniformity and reduce human error. The use of durable, corrosion-resistant materials extends the lifespan of the equipment. Smaller-scale mixers support flexible production, which helps startups and niche brands. Newer models also focus on sustainability, using less energy and producing less waste. These features make vacuum emulsifying mixers a smart investment for any cosmetics or sunscreen producer.

Vacuum emulsifying mixers deliver clear benefits for cosmetics and sunscreen production. These machines create 光滑的, 无气泡产品 with better texture and appearance. Manufacturers save time by combining mixing and debubbling in one step. Safety improves because the closed system limits air exposure and makes cleaning easier. Guangzhou Guanyu stands out with strong technical support, 全球服务, 和定制解决方案. Many experts recommend upgrading to this advanced technology for reliable and efficient results.

常问问题

What products can manufacturers make with a vacuum emulsifying mixer?

Manufacturers can produce creams, 乳液, sunscreens, 药膏, 凝胶, 和血清. The mixer works well for both water-based and oil-based formulas. It also handles high-viscosity materials and sensitive ingredients.

真空乳化混合器如何改善产品质量?

The mixer creates fine, uniform emulsions. It removes air bubbles and prevents oxidation. This process gives products a smooth texture and longer shelf life. Customers notice better appearance and performance.

Is the cleaning process difficult for these machines?

不, cleaning is simple. Most vacuum emulsifying mixers feature automatic Clean-In-Place (CIP) 系统. Stainless steel parts and mirror-polished surfaces help operators clean the machine quickly and thoroughly.

Can manufacturers customize the mixer for different production needs?

是的, manufacturers can request custom features. Guangzhou Guanyu offers options for size, 混合速度, 加热方法, 和控制系统. This flexibility helps companies meet specific production goals.

What support does Guangzhou Guanyu provide after purchase?

Guangzhou Guanyu offers a 2-year warranty, 终身维护, and global technical support. Engineers assist with installation, 训练, 和故障排除. Detailed manuals and instructional videos help operators use the equipment confidently.

Was looking for something different and stumbled upon lucky804. Not bad at all! 查看 lucky804 out to see if you like it!

Having a blast over at fun222! Lots of fast games, the slots are fun, and the bonuses keep things interesting. I’ve recommended it to me friends as well, try it out for yourself!: fun222

你的观点引起了我的注意并且非常有趣. 谢谢. 我有个问题想问你.