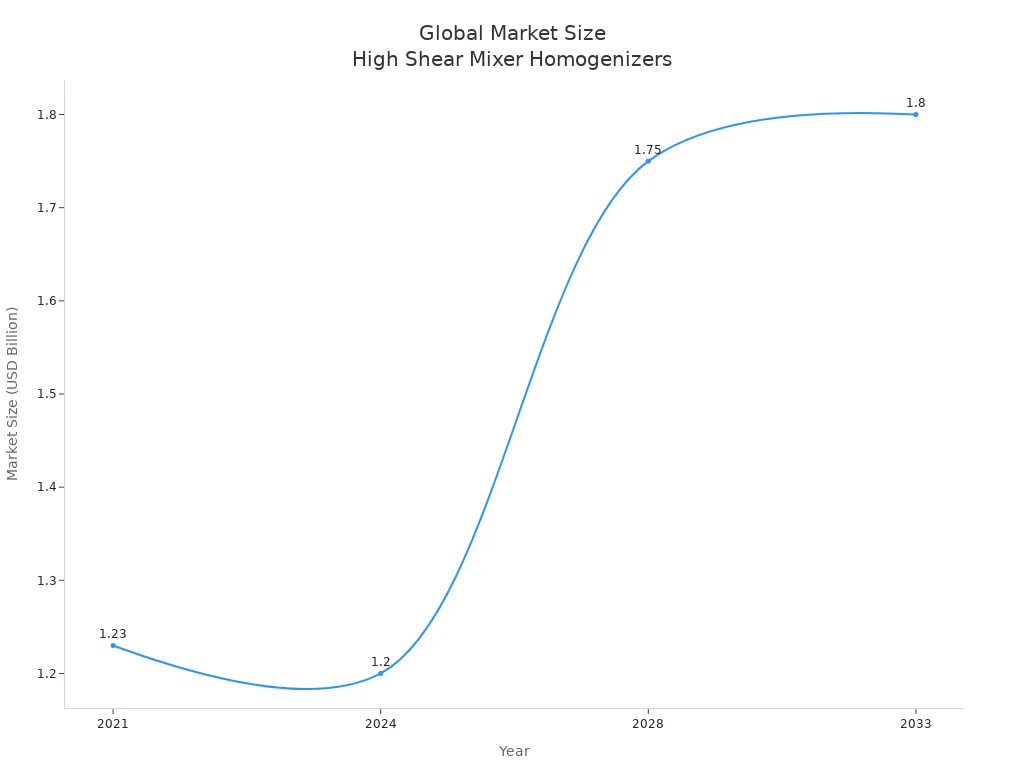

A high shear mixer homogenizer stands out as a powerful device that uses strong forces to blend, emulsify, and break down materials into smooth, even mixtures. This technology supports many industries, including food, pharmaceuticals, and chemicals. The global market for these machines reached $1.2 billion in 2024 and continues to grow steadily.

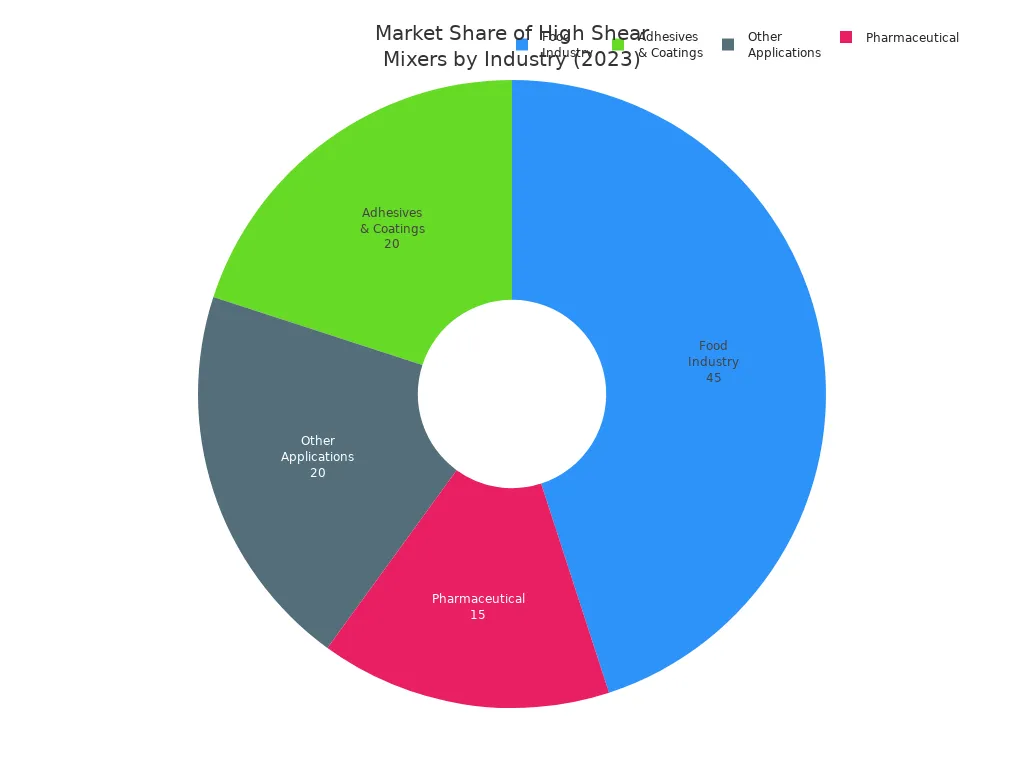

Food production holds the largest share, about 45%, while adhesives, coatings, and pharmaceuticals also use this equipment for quality and consistency.

Key Takeaways

High shear mixer homogenizers blend, emulsify, and break down materials to create smooth, even mixtures that improve product quality and consistency.

These machines use a fast-spinning rotor inside a stator to create strong forces like shearing, cavitation, and turbulence that mix ingredients thoroughly.

Batch mixers suit small to medium production with flexible control, while inline mixers handle large, continuous production with less downtime and contamination risk.

High shear mixers work well for thick materials and quick mixing, but homogenizers produce finer, more uniform mixtures for products like medicines and milk.

Choosing the right mixer depends on product type, batch size, cleaning needs, and safety standards; consulting experts helps find the best fit for each process.

High Shear Mixer Homogenizer Basics

What It Does

A high shear mixer homogenizer performs several important functions in manufacturing and processing. These machines help companies create products with smooth textures and even mixtures. Here are the main tasks they handle:

Emulsifying: They blend liquids that do not usually mix, such as oil and water, into stable emulsions.

Homogenizing: They break down large particles into much smaller ones, making mixtures uniform and smooth.

Dispersing: They spread solid particles evenly throughout a liquid, preventing clumps.

Grinding: They reduce the size of solid materials, which helps create fine powders or pastes.

Dissolving: They help solids dissolve faster in liquids, speeding up production.

These actions improve product consistency and quality. For example, in the food industry, a high shear mixer homogenizer creates creamy sauces and smooth dairy products. In pharmaceuticals, it ensures that medicines have the same amount of active ingredient in every dose. The machine also saves time and energy, making production more efficient and reducing waste.

Tip: High shear mixer homogenizers help companies control the texture and stability of their products, which is important for customer satisfaction.

How It Works

The high shear mixer homogenizer uses a special mixing head called a rotor-stator assembly. The rotor spins at very high speeds inside the stator, which stays still. This setup creates strong forces that break down particles and mix ingredients thoroughly.

Three main scientific principles make this process work:

Principle | Description | Role in Mixing |

|---|---|---|

Shearing | Fluid layers move at different speeds, causing friction. | Breaks up large particles and droplets, making mixtures smooth. |

Cavitation | Fast movement causes tiny bubbles to form and burst. | The bursting bubbles create shockwaves that help break down particles. |

Turbulence | The liquid moves in swirling patterns. | These swirls mix everything together and help make the mixture even. |

The rotor pulls the mixture through a narrow gap between itself and the stator. This action creates intense shear forces, turbulence, and cavitation. As a result, the machine quickly reduces particle size and blends even tough ingredients. The process produces fine, stable emulsions and dispersions, which last longer and look better.

High shear mixer homogenizers can handle many types of products, from thin liquids to thick pastes. They work well for both small and large batches.

Key Components

A high shear mixer homogenizer has several important parts that work together to achieve effective mixing:

Rotor-Stator Assembly: The heart of the machine. The rotor spins at high speed inside the stator, creating the shear forces needed for mixing.

Mixing Blades and Impellers: These attach to the rotor and help move the fluid, breaking up particles and blending ingredients.

Motor: Powers the rotor, allowing it to spin fast enough to generate strong forces.

Seals and Bearings: Keep the machine running smoothly and prevent leaks or contamination.

Control System: Lets operators adjust speed and other settings to match the needs of each product.

Some machines also have extra attachments for special tasks. The design of the rotor and stator, including the shape and size of holes or slots, affects how well the machine mixes different materials. Companies can choose different designs to get the best results for their products.

Note: Easy-to-clean parts and strong seals help keep products safe and meet hygiene standards, especially in food and pharmaceutical industries.

Types

Batch

Batch high shear mixer homogenizers work inside a single tank or vessel. Operators add all ingredients at once, then start the mixing process. The machine uses a single high shear head to blend, emulsify, or disperse the materials. This type allows for precise control over mixing time and ingredient ratios. Batch mixers handle a wide range of viscosities and are easy to move between vessels. They suit products that need careful attention, such as creams, sauces, or adhesives. Cleaning is needed between batches, but the process is flexible and fast for many recipes.

Tip: Batch mixers help companies test new formulas or make small production runs before scaling up.

Inline

Inline high shear mixer homogenizers operate within a closed system, usually as part of a pipeline. The machine draws in ingredients and mixes them as they flow through the rotor-stator assembly. This design creates intense shear forces continuously, making it ideal for large-scale or nonstop production. Inline mixers save time because they do not require stopping between batches. They also reduce the risk of contamination since the system stays closed during operation. Many factories use inline mixers for products like beverages, lotions, or paints.

Type | Best For | Key Features |

|---|---|---|

Batch | Small to medium batches | Flexible, precise, easy to clean |

Inline | Continuous production | Fast, closed system, less downtime |

Lab vs. Industrial

Lab-scale high shear mixer homogenizers have small capacities, often from 0.25 to 12 liters. Scientists and engineers use them for research, testing, or pilot batches. These machines deliver the same mixing quality as larger models but handle much smaller amounts. Industrial-scale mixers can process from a few liters up to 40,000 liters. They use the same rotor-stator technology, so results in the lab can match those in full production. Industrial models focus on high throughput and efficiency, while lab models offer easy setup and quick changes for experiments.

Note: Both lab and industrial high shear mixer homogenizers provide reliable results, making it easy to move from testing to full-scale manufacturing.

Comparison with Other Equipment

High Shear vs. High Pressure

High shear mixers and high pressure homogenizers both help create smooth, even mixtures, but they work in different ways. High shear mixers use fast-moving blades to break down particles and mix ingredients. High pressure homogenizers push materials through a narrow gap at very high pressure, which makes the mixture even finer.

Key performance metrics help compare these two machines. High pressure homogenizers achieve smaller and more uniform particle sizes. They create smoother products with better consistency. High shear mixers handle larger volumes and thicker materials. They also allow for better control over mixing intensity.

Performance Metric | High Shear Mixer | High Pressure Homogenizer |

|---|---|---|

Larger starting sizes | Smaller final sizes | |

Size Distribution | Less uniform | More uniform |

Processing Speed | Slower, variable | Faster, consistent |

Volume & Viscosity Handling | Larger, thicker samples | Limited by volume and viscosity |

Product Consistency | Less uniform | More uniform |

Ultra-high shear mixers can sometimes match or even outperform high pressure homogenizers. They work faster, clean more easily, and handle sticky or thick materials better. High pressure homogenizers excel at making very fine, stable emulsions, especially in food and medicine.

Note: High shear mixers use more energy than some other mixing machines. Static mixers, for example, use less energy but may not achieve the same smoothness.

Pros and Cons

Each type of mixing equipment has its own strengths and weaknesses. The choice depends on the product and the process.

Equipment Type | Disadvantages | |

|---|---|---|

High Shear Mixer | – Rapid mixing for quick blends | – Cannot make the finest emulsions |

Homogenizer | – Makes very fine, uniform mixtures | – Slower mixing |

High shear mixers work well for quick mixing and thick products like adhesives or creams.

Homogenizers suit products that need very fine, stable mixtures, such as milk or medicine.

Ultra-high shear mixers offer high speed, easy cleaning, and less clogging, making them good for large batches and sticky materials.

Some factories use both machines together. They mix thick ingredients with a high shear mixer first, then use a homogenizer for a smooth finish.

Tip: Choose the right equipment based on the product’s texture, volume, and how fine the mixture needs to be.

Applications and Benefits

Industry Uses

A high shear mixer homogenizer serves many industries by making products smoother, more stable, and easier to produce. Companies in pharmaceuticals, personal care, chemicals, and food all use this machine for different reasons. The table below shows some common applications and the benefits each industry gains:

Industry / Application Area | Common Applications | Benefits Provided |

|---|---|---|

Pharmaceuticals | Submicron emulsions for eye drops, creams, antibiotics, drug suspensions, and active ingredients | Finer particle size, faster processing, better product quality, can replace several machines |

Personal Care & Cosmetics | Lotions, sunscreens, pigment dispersions, cosmeceuticals | Smaller footprint, easier cleaning, lower costs, simple maintenance |

Chemicals | Wood stains, resin suspensions, sizing emulsions | Better dispersion, shorter process time, less energy use |

Food & Beverage | Beverages, flavor dispersions, supplements, sauces, condiments | Improved texture and stability, faster production, higher efficiency, cost savings |

Many factories choose this equipment because it mixes ingredients quickly and evenly. It also helps reduce costs and saves time. The machine can handle thick creams, thin liquids, and everything in between.

Tip: High shear mixer homogenizers help companies make products that look and feel the same every time, which keeps customers happy.

Product Quality

High shear mixer homogenizers improve product quality by breaking down particles into very small, even sizes. This process makes mixtures smooth and stable. In pharmaceuticals, the machine ensures each dose has the same amount of medicine. In cosmetics, it creates creams and lotions that feel soft and spread easily. Food companies use it to make sauces and dressings that do not separate.

These machines also speed up production. They help companies make more products in less time without losing quality. For example, longer mixing times with a high shear mixer homogenizer can lower the creaming index in emulsions, which means the mixture stays stable and does not separate. A study showed that increasing mixing time from 10 to 15 minutes reduced the creaming index from about 16.23% to 14.63%, showing better stability.

High shear mixer homogenizers create strong forces that break up clumps and mix everything evenly.

They help companies control texture, color, and stability, making products safer and more effective.

The machine also helps with quality control, so every batch meets the same high standards.

🧪 Consistent mixing leads to safer medicines, smoother creams, and tastier foods.

Choosing the Right Mixer

Key Factors

Selecting the best high shear mixer homogenizer depends on several important factors. Companies should consider these points before making a decision:

Product Type and Properties: The viscosity, density, and particle size of the material affect mixer choice. Some products need gentle mixing, while others require strong shear forces.

Batch Size and Production Scale: The mixer must match the current production volume and allow for future growth. Lab-scale mixers suit small batches, while industrial models handle large volumes.

Mixer Design and Type: Rotor-stator mixers work well for emulsifying and dispersing. Inline mixers fit continuous production, and batch mixers suit flexible recipes.

Material Compatibility: The mixer’s parts should resist corrosion and not react with the product. Stainless steel is common for food and pharmaceuticals.

Mixing Speed and Shear Rate: Adjustable settings help achieve the right texture and consistency.

Ease of Cleaning and Maintenance: Machines with easy disassembly or self-cleaning features save time and reduce downtime.

Safety and Compliance: The mixer should meet industry standards, such as FDA or cGMP, and include safety features like emergency stops.

Cost and Energy Efficiency: Companies should balance purchase price, energy use, and maintenance costs. High-quality mixers often save money over time.

Tip: Always check if the mixer can be customized with attachments or automation to fit special needs.

Practical Tips

Different industries have unique needs when choosing and using a high shear mixer homogenizer. The table below shows practical advice for common sectors:

Industry | Practical Tips | Recommended Mixer Types |

|---|---|---|

Food & Beverage | Use dispersion mixers for powders and rotor-stator mixers for smooth sauces. Choose inline mixers for nonstop production. | Batch, Inline, Rotor-Stator |

Pharmaceuticals | Pick inline mixers for large batches and benchtop mixers for research. Ensure the mixer meets hygiene standards. | Inline, Batch, Benchtop |

Cosmetics | Select mixers that create stable emulsions and distribute pigments evenly. Dual shaft mixers help with thick creams. | Rotor-Stator, Dual Shaft, Dispersion |

Operators should always follow maintenance schedules. Regular cleaning, checking seals, and replacing worn parts keep the mixer running well. Safety features like emergency stops and protective covers protect workers. For regulated industries, mixers must use materials like 316L stainless steel and support clean-in-place systems.

🛠️ Consult with experts or manufacturers to test the mixer with your product before buying. This step helps ensure the best fit for your process.

A high shear mixer homogenizer uses rapid mechanical energy to blend, emulsify, and reduce particle size in many products. Professionals who understand its types and applications can select the right equipment for their needs, improving product quality and safety. Many industries rely on these machines for their versatility and efficiency. For complex requirements, experts recommend consulting resources like the MXD Process blog or experienced manufacturers for guidance and support.

FAQ

What is the main difference between a high shear mixer and a blender?

A high shear mixer uses a rotor-stator system to create strong forces that break down particles. A blender mixes ingredients but does not achieve the same fine, uniform results.

Can a high shear mixer homogenizer handle hot or cold materials?

Yes, most high shear mixer homogenizers work with both hot and cold materials. Operators should check the machine’s material compatibility and temperature limits before use.

How often should operators clean a high shear mixer homogenizer?

Operators should clean the machine after each batch or production run. Regular cleaning prevents contamination and keeps the equipment running smoothly.

What safety features do high shear mixer homogenizers include?

Most machines have emergency stop buttons, safety covers, and automatic shut-off systems. These features protect operators and help prevent accidents.

**gl pro**

gl pro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/register?ref=IHJUI7TF

Yo, Rummy91login is actually pretty decent! Got some good bonuses when I signed up and the games run smoothly. Haven’t had any major issues, just wish they had a bigger tournament schedule. Worth checking out though! Learn more at rummy91login.

Just tried 444wim, and it’s pretty cool! The interface is smooth, and I love the selection. Definitely worth checking out. You can find it here: 444wim

Hi there excellent website! Does running a blog such as this take a massive amount work?

I have absolutely no expertise in coding but I was hoping

to start my own blog soon. Anyway, should you have any recommendations

or techniques for new blog owners please share.

I understand this is off topic but I simply had to ask.

Thank you!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.info/sl/register?ref=I3OM7SCZ