A vacuum mixer homogenizer is a specialized machine that mixes, emulsifies, homogenizes, and disperses thick materials under vacuum. This equipment uses powerful mixing and high-speed shear to create smooth, stable products without air bubbles. Operating under vacuum helps prevent oxidation and improves product quality. Many industries, such as cosmetics and pharmaceuticals, rely on these machines.

Metric | Value (USD) | Timeframe | CAGR (%) |

|---|---|---|---|

Global market size for vacuum homogenizer emulsifying mixer machines | 2024 | N/A | |

Projected market size | 200 million | 2033 | 6.5% (2026-2033) |

Key Takeaways

A vacuum mixer homogenizer blends thick materials under vacuum to create smooth, bubble-free products with longer shelf life.

The machine uses high-speed mixing and shear forces to break down particles, ensuring even texture and stable emulsions.

Vacuum removes air and prevents oxidation, which keeps products fresh, preserves nutrients, and improves quality.

This equipment suits many industries like cosmetics, food, pharmaceuticals, and chemicals, helping produce consistent, high-quality items.

Advanced features like temperature control and easy cleaning make vacuum mixer homogenizers efficient and reliable for modern production.

Vacuum Mixer Homogenizer Basics

What It Is

A vacuum mixer homogenizer is a machine that blends, emulsifies, and homogenizes thick or viscous materials under vacuum conditions. This equipment creates a negative pressure inside a sealed vessel, which removes air and prevents bubbles from forming in the product. The vacuum environment helps stop oxidation and keeps the product fresh and stable. Many industries use this technology to make creams, ointments, sauces, and lotions. The process starts by loading raw materials into the vessel. The vacuum system then removes air, and the mixing and homogenizing systems work together to create a smooth, even mixture. Operators can control speed, temperature, and vacuum level for each batch. This control ensures consistent results and high product quality.

Note: Vacuum emulsifier homogenizer machines combine mixing, emulsification, and homogenization in one step. This process produces fine, stable emulsions with improved texture and longer shelf life.

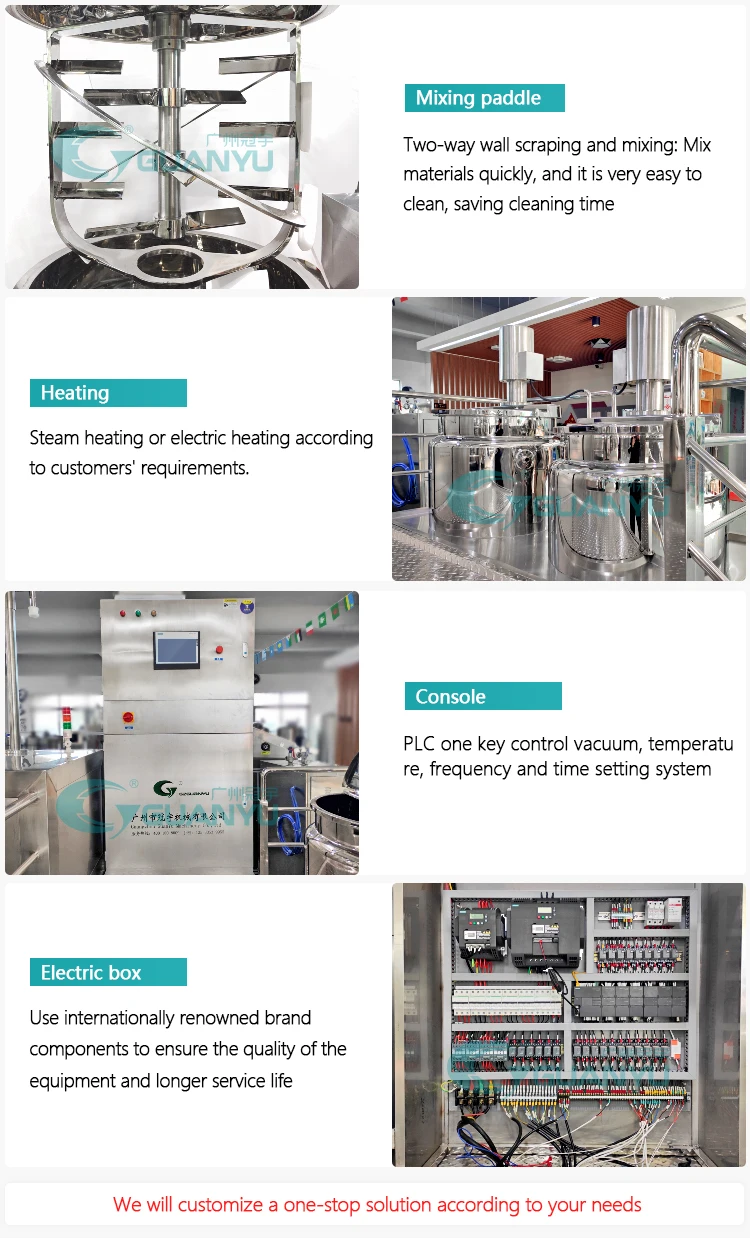

Main Components

A vacuum mixer homogenizer contains several important parts, each with a special job:

Mixing Chamber: This is the main area where materials blend under vacuum. It is made of stainless steel and can handle high pressure and temperature.

Vacuum System: The vacuum pump removes air from the chamber. This step prevents bubbles and improves product stability.

Homogenizer: This part uses a high-speed rotor and stator to break down particles. It creates a fine, even texture and helps with emulsification.

Sealing Device: Seals keep the chamber airtight and stop leaks or contamination.

Transmission Device: This system moves power from the motor to the rotor, making sure everything runs smoothly.

Cooling and Lubrication Systems: These systems control temperature and reduce friction, which protects the machine and the product.

Bolts and Safety Features: Bolts hold the chamber together. Safety features like emergency stop buttons and pressure valves protect operators.

Component | Role in Mixing Process | Importance/Functionality Summary |

|---|---|---|

Mixing Chamber | Blends materials under vacuum | Ensures efficient mixing and withstands pressure |

Rotor | Moves and blends materials | Creates shear forces for consistency |

Vacuum System | Removes air before mixing | Prevents bubbles, improves texture |

Homogenizer | Breaks down particles | Ensures smooth texture and stable emulsification |

Sealing Device | Prevents leaks and contamination | Maintains safety and product quality |

Transmission Device | Transfers power from motor to rotor | Enables smooth operation |

Cooling System | Regulates temperature | Prevents overheating |

Lubrication System | Reduces friction and wear | Extends equipment lifespan |

Bolts | Secure chamber and components | Maintain stability during operation |

Vacuum emulsifier homogenizer machines often include advanced features like touch screen controls, dual heating options, and energy-efficient motors. These improvements help operators achieve better results with less effort.

How It Works

Mixing and Homogenizing Process

The vacuum mixer homogenizer follows a step-by-step process to create smooth and stable mixtures. Operators begin by loading raw materials into a stainless steel vessel. The vessel uses a vacuum to remove air, which helps prevent bubbles and foaming. A high-speed rotor at the bottom of the vessel spins quickly, breaking up powders and liquids into tiny droplets. This action ensures that the mixture does not form lumps and stays even throughout.

The machine often heats the vessel using a jacket around the chamber. Heating increases the solubility of powders and helps them dissolve faster. Operators can control the temperature, mixing speed, and time for each batch. They may add powders slowly into the swirling liquid to avoid clumps. Sometimes, they pre-mix gums or powders with oil before adding them to the main vessel. This careful process leads to a uniform, agglomerate-free blend.

After mixing and homogenization, the finished product leaves the vessel through a discharge valve or pump. The vacuum mixing process ensures that the final product is smooth, stable, and free from air pockets.

Tip: Adjusting the speed of the agitator and homogenizer helps achieve the best results for different materials.

Role of Vacuum

Vacuum mixing plays a key role in improving product quality. The vacuum removes air from the vessel before and during mixing. This step prevents air bubbles, which can cause defects and make the product less stable. Without air, the risk of bacterial contamination and oxidation drops. The product stays fresh and keeps its color and texture longer.

Vacuum mixing creates a smooth, even texture by stopping air from entering the mixture.

The process helps avoid foaming, which is common in non-vacuum systems.

Products made with vacuum mixing are more stable and have a longer shelf life.

The vacuum mixer homogenizer works well with thick and powder-filled materials, making sure everything blends evenly.

Many industries use vacuum mixing to make cosmetics, food, pharmaceuticals, and chemicals with high quality and consistency.

A vacuum environment also helps the emulsification process. It allows the homogenizer to disperse and mix materials more evenly, leading to delicate and stable products.

Shear and Cavitation

The homogenizer uses powerful forces to break down particles and mix them thoroughly. The rotor spins at high speed near a stationary part called the stator. This setup creates a narrow gap where the liquid moves very fast. The difference in speed between the rotor and stator generates strong shear forces. These forces shatter particles and droplets, making them smaller and more uniform.

Shear force disrupts the smooth flow of liquid, causing turbulence. This turbulence helps blend materials and improves mass transfer. The process also prevents the natural separation of oil and water in emulsions. By reducing droplet size, the homogenizer ensures that the mixture stays stable and does not separate over time.

Cavitation adds another layer of mixing power. When the rotor moves quickly, it creates tiny bubbles in the liquid. These bubbles collapse with great force, sending shockwaves through the mixture. The shockwaves break apart larger particles, helping achieve a fine and even particle size distribution. The vacuum helps by removing unwanted air bubbles, so the final product is smooth and free from defects.

Physical Principle | How It Works in the Homogenizer | Result for the Product |

|---|---|---|

Shear | High-speed rotor-stator action | Smaller, uniform particles and droplets |

Cavitation | Collapsing bubbles from fast movement | Finer particle size and better mixing |

Turbulence | Chaotic fluid motion | Improved blending and stability |

Note: Controlling the shear rate is important. It helps achieve the right particle size and ensures the product remains stable and consistent.

Vacuum Emulsifier Homogenizer Features

Air Removal and Product Quality

A vacuum emulsifier homogenizer uses vacuum deaeration to remove air from the mixing chamber. This process improves the final product in several ways. When air leaves the mixture, the risk of oxidation drops. The product keeps its color, vitamins, and antioxidants. Removing air also prevents unwanted odors and helps the product taste better. The texture becomes smoother and denser, which makes the product look and feel more appealing.

Vacuum deaerators eliminate specific odors, improving taste and overall quality.

Air removal stops oxidation, preserving color and nutrients.

The process creates denser material, which increases production efficiency.

Continuous deaerators remove trapped air and gases from liquids, slurries, and semi-solids.

The vacuum environment improves product stability and shelf life.

Texture, appearance, and consistency all benefit from air removal.

The process works for many products, including creams, ointments, sauces, gels, and adhesives.

A vacuum emulsifier homogenizer uses high-shear mixing to break up any remaining air pockets. This step ensures a uniform and stable mixture. Many industries, such as food, cosmetics, and pharmaceuticals, rely on this technology to deliver high-quality mixing and consistent results.

Efficiency and Consistency

A vacuum emulsifier homogenizer offers high-quality mixing with greater efficiency than traditional mixers. The vacuum removes air, which prevents bubbles and oxidation. This step leads to a smoother, more uniform product. The machine also reduces the risk of cross-contamination by creating a sterile environment.

Vacuum pressure removes air, preserving ingredient quality.

The system eliminates air pockets, ensuring a consistent final product.

Deaeration improves stability and extends shelf life.

Precise temperature and pressure controls allow for tailored mixing.

High automation reduces human error and increases repeatability.

The process accelerates mixing, saving time and reducing waste.

The machine handles a wide range of viscosities and materials.

Operators can adjust speed and time for each batch. Heating and cooling systems help control temperature, which is important for sensitive substances. The vacuum emulsifier homogenizer supports the production of gels, creams, and ointments that require dispersion, dissolution, and emulsion. This versatility makes it a valuable tool for many industries.

Applications

Industries

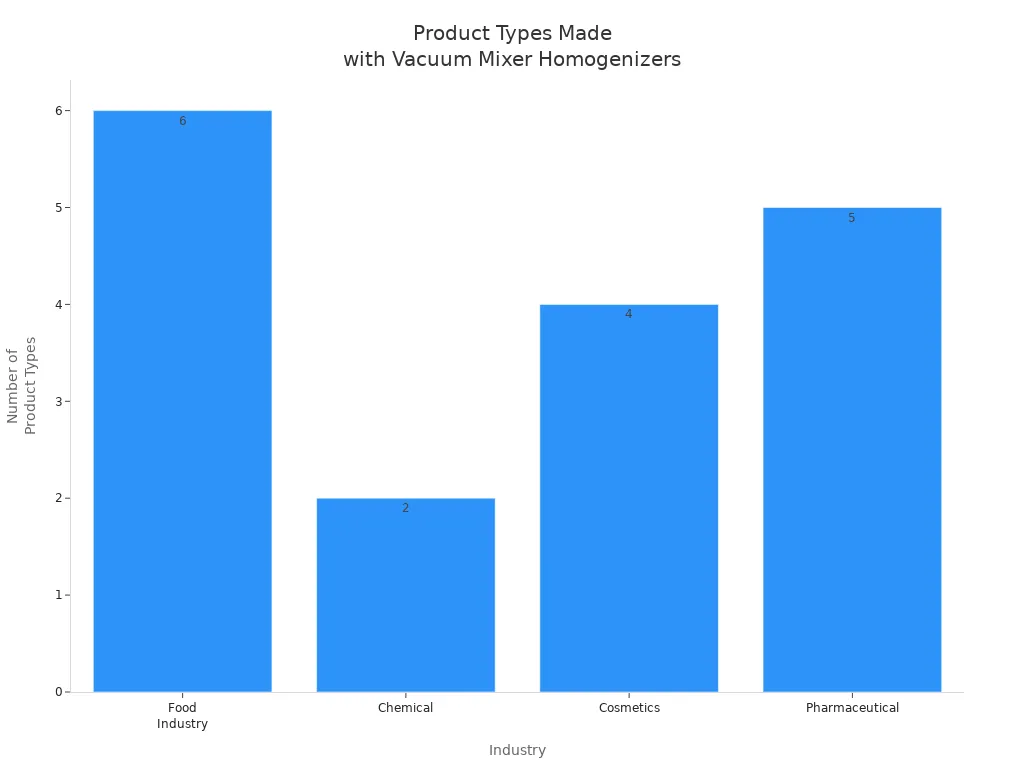

Vacuum mixer homogenizers play a key role in many industries. Companies use them to improve product quality and meet strict standards. The table below shows common industries and how they use these machines:

Industry | Typical Applications and Uses |

|---|---|

Pharmaceuticals | Manufacturing creams, ointments, and lotions; emulsifying thick materials; using steam or electric heat. |

Food Processing | Mixing to preserve nutrition, prevent oxidation, and avoid defects; drying and combining powders and granules. |

Chemical Industry | Drying and blending powders or granules that are heat sensitive or oxidize quickly. |

Insecticide & Pesticide | Processing powders and granules that need low temperature drying and oxidation prevention. |

Heat-Tolerant Goods | Combining and drying raw materials that cannot withstand high temperatures. |

Many companies in these industries choose vacuum mixer homogenizers because they help prevent product recalls. Proper mixing stops separation and ensures a smooth, stable product. For example, in the dairy industry, poor homogenization can cause cream to separate, leading to recalls and customer complaints.

Vacuum mixer homogenizers also help companies meet hygiene and safety standards. Manufacturers build these machines with stainless steel and sanitary materials. Automated cleaning systems keep the equipment clean and safe for food and cosmetics production.

Product Types

Vacuum mixer homogenizers produce a wide range of products. These machines create smooth, stable, and high-quality items. The table below lists some common products and their quality requirements:

Industry | Products Frequently Produced Using Vacuum Mixer Homogenizers | Quality Requirements and Benefits |

|---|---|---|

Food Industry | Sauces, creams, chocolates, coatings, milk, dairy products | Smooth mixing, high density, consistent texture and composition |

Chemical | Paints, coatings | High consistency for efficient application |

Cosmetics | Face moisturizers, creams, serums, skin care products | Uniform mixing, smooth texture, stable emulsions |

Pharmaceutical | Active ingredients, creams, jellies, ointments, emulsions | Preserved chemical composition, uniform particles, stable emulsions, reduced oxidation |

Vacuum mixer homogenizers help companies achieve batch-to-batch consistency. The vacuum environment reduces air contact, which keeps sensitive ingredients safe from oxidation. This process also improves product stability and shelf life. Companies can produce both small and large batches, with some machines handling up to 50,000 liters at a time.

Tip: Consistent mixing and air removal are critical for products like creams, sauces, and paints. These steps help maintain quality, texture, and appearance, which are important for customer satisfaction.

Comparison with Other Mixers

Standard vs. Vacuum Mixer Homogenizer

Mixers come in many types, but not all deliver the same results. A vacuum mixer homogenizer stands out because it creates smooth, bubble-free products. Standard mixers, such as high-shear mixers and colloid mills, use less energy but often leave air in the mixture. This air can cause bubbles, uneven texture, and faster spoilage. Homogenizers use high pressure to make very fine emulsions, but they need more energy and can damage heat-sensitive ingredients.

Equipment Type | Energy Consumption | Product Uniformity and Quality |

|---|---|---|

Vacuum Emulsifying Mixer | Smooth, bubble-free, fine, even particle distribution; vacuum reduces oxidation and air inclusion | |

Standard Mixers (High-Shear, Colloid Mills) | Lower; colloid mills are energy efficient | Coarser particle sizes, less uniform products; less effective for fine emulsions |

Homogenizers | High due to high pressure | Ultra-fine particle size, very stable emulsions; can harm heat-sensitive materials |

A vacuum emulsifier homogenizer uses a closed system. This design keeps out dust and moisture, which helps prevent contamination. The vacuum also lowers the boiling point of liquids, so the machine can process materials at lower temperatures. This feature protects sensitive ingredients and saves energy. The result is a product with better texture, longer shelf life, and less waste.

Note: Vacuum mixer homogenizers require more cleaning and calibration than standard mixers. This extra care helps keep products safe and consistent.

Bottom Vacuum Emulsifier Homogenizer Mixer

The bottom vacuum emulsifier homogenizer mixer offers unique advantages. Its bottom-mounted high-shear homogenizer creates a strong vortex, pulling materials down for efficient mixing. This design improves shear and mixing from below, making it ideal for thick or air-sensitive products.

The bottom vacuum emulsifier homogenizer mixer reduces energy use and improves product consistency.

It combines emulsifying, homogenizing, and vacuum mixing in one compact system.

The bottom-driven structure saves space and makes maintenance easier.

Stainless steel construction supports clean-in-place and sterilize-in-place cleaning.

Enhanced vacuum deaeration prevents foaming and oxidation, boosting product stability.

The bottom vacuum emulsifier homogenizer mixer delivers intense cutting and shear force, creating fine, stable emulsions.

It processes small and viscous batches efficiently, where top-mounted mixers may struggle.

The design allows for faster cleaning, less waste, and more complete discharge of material.

Many industries, such as cosmetics, pharmaceuticals, and food processing, use the bottom vacuum emulsifier homogenizer mixer to produce uniform, stable, and aeration-free mixtures. The compact design and efficient mixing make it a top choice for modern production lines.

Vacuum mixer homogenizers offer many advantages for manufacturers.

They remove air bubbles quickly, prevent oxidation, and create smooth, stable products.

The machines combine mixing, heating, cooling, and homogenizing in one unit, which saves time and reduces waste.

Users report better product consistency, fewer defects, and longer shelf life.

Programmable controls and easy cleaning help companies meet strict quality standards.

These features make vacuum mixer homogenizers a smart choice for industries that need reliable, high-quality production.

FAQ

What is the main benefit of using a vacuum mixer homogenizer?

A vacuum mixer homogenizer removes air from mixtures. This process creates smooth, stable products. It also helps prevent oxidation, which keeps products fresh and extends shelf life.

Can a vacuum mixer homogenizer handle thick or sticky materials?

Yes, this machine mixes thick or sticky materials easily. The strong motor and high-shear blades break down lumps and blend ingredients evenly. Many industries use it for creams, gels, and pastes.

How does the vacuum feature improve product quality?

The vacuum removes air bubbles and gases. This step prevents foaming and defects. Products look better and last longer. The vacuum also helps keep sensitive ingredients safe from oxidation.

Is cleaning a vacuum mixer homogenizer difficult?

Most machines have easy-to-clean designs. Many include clean-in-place (CIP) systems. Operators can wash the inside without taking the machine apart. This feature saves time and keeps the equipment sanitary.

What industries use vacuum mixer homogenizers?

Many industries use these machines. Common examples include cosmetics, food, pharmaceuticals, and chemicals. Each industry values the machine for its ability to create high-quality, uniform products.

**mind vault**

Mind Vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

Looking to download the 7clubsgameapk but want to make sure it’s safe first. Anyone downloaded it and can vouch for it? Don’t want any nasty surprises on my phone! 7clubsgameapk

Gave ubet95casino a whirl. Not too shabby, got a decent selection of games. Took a bit of spinning and it seemed alright. Have a look for yourself: ubet95casino

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.