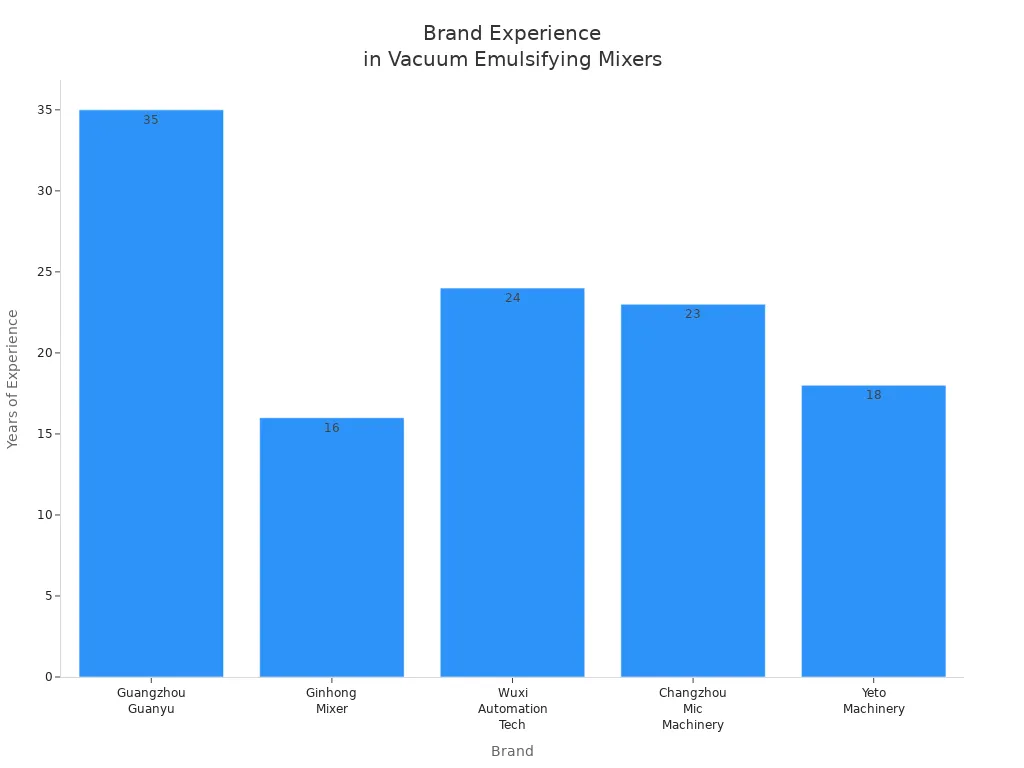

If you want a great vacuum emulsifying mixer for making cosmetics in 2025, you should check out Guangzhou Guanyu. Guanyu has more than 35 years of experience. Guanyu is a leader in the market. They offer custom solutions. They also give strong help after you buy. See how top brands compare:

Brand Name |

|---|

Shang Yuh Machine |

SINA EKATO Chemical Machinery |

YK Machinery |

Ginhong |

MAKWELL MACHINERY |

Yuxiang Light Industry Machinery |

MIZUHO Industrial |

ROSS Mixers |

Guangzhou PM Technology |

Promake |

Guangzhou Guanyu is special because it uses advanced technology. It is also known for being reliable. The chart below shows how much experience Guanyu has compared to other brands:

You can trust a vacuum emulsifier or mixer emulsifier from a company that knows what you need. They help you get high-quality results.

Key Takeaways

Guangzhou Guanyu is special in the vacuum emulsifying mixer market. They have more than 35 years of experience. They care about quality and help their customers.

Picking a vacuum emulsifier with advanced features is important. High-shear homogenizers and a vacuum system make products better. These features help products stay stable and have no air bubbles.

Guanyu offers machines you can customize. You can change the equipment to fit your needs. This helps you do well in the cosmetics industry.

Market Overview

Leading Brands

There are many strong brands in the vacuum emulsifying mixer market. Each brand has special features and technology. These help you make your products better. Here are some top brands and what makes them different:

Brand | Distinguishing Features |

|---|---|

Grandpackmachine | High-performance emulsifying solutions, integrates multiple functions (homogenization, heating, cooling), premium materials, rapid customer service. |

IKA | Offers scalable, modular MASTER-PLANT systems that work well for many types of emulsions and suspensions. |

Silverson | Uses high-shear mixing technology for speed and efficiency, great for emulsifying and dissolving solids. |

These brands use advanced technology and are very reliable. This helps you get the same results every time you make cosmetics.

Industry Trends

The vacuum emulsifying mixer market is getting bigger every year. Here are some important facts and trends:

The global market size for vacuum emulsifying mixers in the cosmetics sector is estimated at $1,083 million in 2025.

Projections show the market could reach nearly $2 billion by 2033, with a CAGR of 7.5%.

Asia-Pacific countries like Japan, Malaysia, and South Korea lead in adoption due to strong demand.

Germany and Canada also show fast growth, with Germany expected to reach USD 200 million by 2028.

In 2025, you will see more machines with automation and smart controls. Many mixers will use less energy. Companies want to be more eco-friendly and use natural products. These changes help you follow new rules in the industry.

Guangzhou Guanyu Overview

Company Strengths

You want a partner with lots of experience and a smart team. Guangzhou Guanyu began in 2010. They make machines for medicine, daily chemicals, food, and industry. Guanyu is known for making good products and new ideas.

Founding Year | Company Focus |

|---|---|

2010 | Research and manufacture of pharmaceutical chemicals, daily-use chemicals, food chemicals, and industrial chemical machinery. |

Guanyu’s technical team is very skilled. You get help from experts for every step. The team has artwork designers, technicians, sales staff, and service specialists. Each person has special skills to help you.

Role | Expertise Area |

|---|---|

Artwork Designers | Product aesthetics and functionality |

Skilled Technicians | Machinery quality standards |

Sales Personnel | Client needs and tailored solutions |

After-sales Service | Long-term machinery performance support |

Guanyu gives you everything in one place. You can find all the machines you need for your factory. They have vacuum emulsifier machines, cream gel making machines, mixing machines, storage tanks, and filling machines.

Product Category |

|---|

Vacuum Emulsifier Machine |

Cream Gel Making Machine |

Mixing Machine |

Storage Tank |

Filling Machine |

Guanyu cares a lot about quality. You can trust that every machine gets checked carefully. They use quality assurance and quality control steps:

Quality Assurance (QA): Guanyu sets rules for suppliers to stop problems early.

Quality Control (QC): The team checks finished machines for mistakes before shipping.

Here are the steps Guanyu follows:

Pre-Production Inspections: They check samples and materials before making lots of machines.

In-Process Inspections: The team watches production to fix problems fast.

Pre-Shipment Inspections: Finished machines get checked to make sure they work well.

Container Loading Inspections: Guanyu makes sure machines are loaded safely and labeled right.

Guanyu helps you after you buy too. You get a two-year warranty and help for life. The service team helps with setup, training, and support. This keeps your factory working well and saves you time.

Tip: Picking a company with good after-sales help stops problems and keeps your business running.

Custom Making Machine

Sometimes you need a machine made just for you. Guanyu is great at making custom machines. You can ask for changes to the logo, packaging, graphics, or size. They also do small changes, drawing changes, sample changes, and full custom jobs. You only need to order one set to start.

Customization Option | Minimum Order |

|---|---|

Customized logo | |

Customized packaging | 1 set |

Graphic customization | 1 set |

Size Customized | 1 set |

Minor customization | N/A |

Drawing-based customization | N/A |

Sample-based customization | N/A |

Full customization | N/A |

You can work with Guanyu’s team to design your machine. The company listens to what you want and helps you get the right solution. This makes Guanyu a smart pick for companies who want to be different in cosmetics.

Note: Custom machines help you keep up with new trends and customer needs. You can stay ahead with equipment made just for you.

Vacuum Emulsifying Mixer Features

Advanced Technology

You want a vacuum emulsifier made with strong, safe materials. Most top machines use SUS316L or SUS304 stainless steel. These materials do not rust and last a long time. They are easy to clean. This helps keep your products safe and high quality.

Vacuum emulsifying mixers use new technology to help you make better cosmetics. The vacuum system keeps air out of the mix. This stops bubbles and oxidation. Your creams and lotions stay smooth and stable. High-shear homogenizers break down ingredients fast. You get a fine texture and even blend. The mixer emulsifier uses fast impellers and scrapers. Scrapers clean the tank walls so nothing sticks. You get a uniform mix every time.

Tip: Pick a mixer with high-shear homogenizers and a vacuum tank. This helps you make safe and high-quality products.

Here is a quick look at the main features:

Feature | Description |

|---|---|

SUS316L/SUS304 | Strong, does not rust, easy to clean |

Vacuum System | Keeps air out, stops bubbles and oxidation |

High-Shear Homogenizer | Breaks down ingredients for a smooth texture |

Scraper Function | Cleans tank walls, stops dead spots |

Smart Controls | Lets you change speed and temperature for each product |

Efficiency & Quality

You need a vacuum emulsifier that works well with thick mixtures. These mixers handle heavy creams and gels. You get stable emulsions and suspensions. The vacuum emulsifying mixer blends ingredients fast and evenly. You save time and energy.

Your creams have high stability and a fine texture.

The mixer emulsifier uses high shear for good mixing.

You can make many cream products quickly and with great quality.

The vacuum sealing system keeps your ingredients safe. It stops air from getting in and keeps your product fresh. You can trust these machines for special cosmetic needs.

Here is how a vacuum emulsifier helps you:

Equipment Type | Made for thick mixtures and mixing under vacuum. |

|---|---|

Mixing Mechanism | Uses fast impellers and homogenizers for even blending. |

Air Incorporation | Stops air from getting in, so no bubbles form. |

Scraper Function | Scrapers clean tank walls for a uniform mix. |

Application | Best for complex cosmetics, stable emulsions, and suspensions. |

The vacuum emulsifying mixer lets you control every step. You can change speed, temperature, and mixing time. This helps you meet strict quality rules. You get the same good results every time.

Note: Using a vacuum emulsifier with smart controls and strong materials helps you make safe, high-quality products. You can meet customer needs and follow industry rules with confidence.

Mixer Emulsifier Customization

Flexible Solutions

You need a mixer emulsifier that works for your special formulas. Guangzhou Guanyu gives flexible choices to cosmetics makers. Their team helps you make custom machines for creams and suspensions. You get help with setup and training. This makes sure your machines run well and your products are good.

Customization Aspect | Description |

|---|---|

Custom Machines | Guangzhou Guanyu provides custom machines tailored for specific cosmetic formulations. |

Design Assistance | Their team assists customers in designing machines that fit their unique formulas and packaging. |

Setup and Training | The company offers setup services and training for workers to ensure smooth operation of machines. |

You can pick from many mixer emulsifier models. The vacuum emulsifying mixer has a heating and cooling jacket. This lets you control the temperature. Good temperature control helps your products stay high quality. You can choose a vacuum cream mixer or the ZJR Series vacuum emulsifying mixer. These mixers use high-shear homogenizers for strong mixing. These choices help you get the same quality every time and make your work better.

Production Scale

How much you make decides which mixer emulsifier you need. If you make small batches, use a vacuum emulsifying tank with 20L or 30L size. For bigger jobs, pick a vacuum homogenizer mixer with 200L size. Figure out how much you make each day to choose the right size. Planning for growth is smart. If you buy a mixer that is big enough now, you will not need to upgrade soon.

Different models work for different amounts you make.

Picking the right mixer emulsifier keeps your creams and suspensions stable.

High-shear homogenizers help you keep good quality no matter the size.

Tip: When your mixer matches your production size, you can always make good products and keep your customers happy.

User Feedback & Support

Real Experiences

It is important to know what users think about Guangzhou Guanyu mixers. Many people who make cosmetics say good things about these machines.

One customer said, “My Guanyu mixer always works. Every batch is perfect.”

The Vacuum Emulsifying Mixer is great for making smooth creams and lotions.

You can change the settings for each recipe. This helps you keep every batch high quality.

Many users talk about the strong after-sales support. You get help when you need it. This keeps your production going and your products good.

You can count on these mixers for creams and suspensions. The machines help you reach the quality your customers want.

Service & Warranty

Guangzhou Guanyu gives you peace of mind with service and warranty. You get a two-year warranty and help for life. Their team answers questions any time, day or night. If you need help, they send videos or an engineer to your place.

Warranty Duration | Maintenance Type | Additional Support |

|---|---|---|

2 Years | Lifetime | 24/7 consulting, solution videos, on-site engineer support if needed |

When you look at after-sales support, Guanyu is ahead:

Feature | Guangzhou Guanyu | Competitors |

|---|---|---|

International Service Points | More than 5 | Fewer or none |

Customer Service Availability | Limited hours | |

Pre-shipment Testing | Careful with customer videos | May not offer testing |

Picking a mixer with strong support helps you keep your products good and your business running well.

Vacuum Emulsifier Future Trends

Smart Controls

In 2025, vacuum emulsifying mixers will have more smart controls. These new features make it easier to make cosmetics. You do not have to work as hard. The machines are more accurate too. Many mixers now have a PLC control system. You can use a touch screen to change settings. This is helpful if your hands are dirty from work. Automatic valves and suction systems move things in and out of the mixer. You do not need to open or close anything by hand. You can also save recipes for each product. This lets you make the same cream or lotion again with one touch.

Feature | Description |

|---|---|

PLC Control System | Lets you change all settings on a touch screen. |

Automatic Pneumatic Valves | Moves pipes and fittings for you. |

Automatic Suction | Pulls materials into the main pot without manual work. |

Automatic Discharge | Empties finished products automatically. |

Intelligent Recipe System | Saves and recalls settings for each product you make. |

Tip: Smart controls help you work faster and make fewer mistakes. You can focus on quality and creativity.

Sustainability

You want machines that use less energy and last longer. New vacuum emulsifying mixers save more power than old ones. They have strong parts that do not break easily. You will not need to buy new machines often. You also pay less for energy. Many mixers now have special heating and cooling systems. These use less energy. Some mixers can even reuse water or steam.

Every batch has the same good quality

You can work fast and waste less

Each product uses less energy

Feature | Benefit |

|---|---|

Vacuum Technology | Uses less energy while mixing and blending |

Efficient Heating/Cooling | Cuts down on power needed for temperature control |

Condensate Recovery Systems | Reduces waste and improves overall efficiency |

Guangzhou Guanyu and other top brands keep adding smart and green features. These machines help your business grow and protect the planet at the same time.

You should pick Guangzhou Guanyu and other top mixers in 2025. These mixers help you make smooth and stable products with no air bubbles. You can use them for many different formulas. The design keeps things clean and makes cleaning simple. Automation and monitoring give you better control over your work. Always watch for new trends. Mixer technology will keep changing how you make cosmetics.

FAQ

What materials do vacuum emulsifying mixers use?

These mixers are made from SUS316L or SUS304 stainless steel. These metals do not rust. They help keep your products safe.

How does Guangzhou Guanyu support you after purchase?

You get a two-year warranty.

You can get maintenance for life.

The team helps set up your machine and trains you.

Can you customize a mixer for your formula?

Option | Available? |

|---|---|

Logo | ✅ |

Packaging | ✅ |

Size | ✅ |

Full Custom | ✅ |

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.info/ka-GE/register-person?ref=ILE8IH9H

Hey! Just checked out codeqq88, and honestly, it’s pretty solid. Found some interesting stuff there. Definitely worth a look if you’re looking for something new. Check it out: codeqq88

4rabet is my go-to for Cricket betting, especially IPL. Great platform and reliable. If you’re not sure, check this official or fan link: 4rrabet

Heard about ph365betsignup. The signup process seems straightforward enough. If you’re looking for a new betting site, you might want to check them out. Check their signup process here: ph365betsignup

Downloaded the ph350app earlier today. The user interface is clean and it does what it says on the tin. Recommend it if you need a simple and reliable app. Download now: ph350app

Just downloaded the 73bet app – runs smooth as butter! Seriously, the interface is clean, and finding my favorite games was a breeze. Definitely worth checking out! Play responsibly everyone! Check it out for yourself at: 73betappdownload