What is an Emulsifier Machine?

Emulsifier machines play a crucial role in the production of a wide range of products, from food and cosmetics to pharmaceuticals and chemicals. These specialized Emulsifier Machines are designed to create stable emulsions by thoroughly mixing two or more immiscible liquids, such as oil and water.

The purpose of an Emulsifier Machine is to break down large droplets of one liquid into smaller, evenly dispersed droplets within another liquid, resulting in a homogeneous and stable mixture. This process is essential for creating products with desirable textures, appearances, and shelf-life.

There are several types of Emulsifier Machines available, each with its own unique features and capabilities. Some of the most common types include high-shear Emulsifier Machines, colloid mills, and ultrasonic Emulsifier Machines.

What are the differences between a high-shear and low-shear Emulsifier Machine?

High-shear Emulsifier Machines use a combination of high-speed rotation and specialized impellers to generate intense shear forces that quickly break down large droplets into smaller ones. This results in a finer emulsion with a more uniform particle size distribution. High-shear Emulsifier Machines are often used for producing low-viscosity emulsions, such as those found in personal care products and certain food applications.

In contrast, low-shear Emulsifier Machines rely on gentler mixing actions, such as slow-speed agitation or simple propeller blades, to create emulsions. These machines typically produce a coarser emulsion with a wider range of droplet sizes. Low-shear Emulsifier Machines are better suited for high-viscosity products, such as creams and ointments, where excessive shear could damage sensitive ingredients.

How Do Emulsifier Machines Work?

The emulsification process carried out by these Emulsifier Machines is based on the principles of fluid dynamics and surface chemistry. The key components of an Emulsifier Machine include the mixing chamber, the rotor-stator assembly, and various adjustable parameters such as speed, temperature, and processing time.

During the emulsification process, the two immiscible liquids (typically an oil and an aqueous phase) are introduced into the mixing chamber. The rotor-stator assembly then applies high shear forces to the mixture, breaking down the larger droplets of one liquid into smaller, evenly dispersed droplets within the other liquid. This is achieved through a combination of intense mechanical agitation, turbulence, and the creation of a high-pressure gradient within the chamber.

The adjustable parameters of the Emulsifier Machine, such as rotational speed, temperature, and processing time, can be carefully controlled to optimize the emulsification process for different product formulations and desired characteristics. By manipulating these parameters, manufacturers can achieve the desired droplet size, viscosity, and stability of the final emulsion.

Applications of Emulsifier Machines

Emulsifier Machines find widespread use in a variety of industries, each with its own unique requirements and specifications. Some of the key applications include:

Food and Beverage Industry

In the food and beverage sector, Emulsifier Machines are used to create stable emulsions for products such as mayonnaise, salad dressings, sauces, ice cream, and various dairy products. The emulsification process helps to achieve the desired texture, mouthfeel, and shelf-life of these products.

Cosmetics and Personal Care Products

Emulsifier Machines play a crucial role in the production of cosmetics and personal care products, such as lotions, creams, ointments, and sunscreens. The emulsification process ensures the uniform distribution of active ingredients, oils, and water-based components, resulting in products with desirable sensory properties and stability.

Pharmaceutical and Chemical Industries

In the pharmaceutical and chemical industries, Emulsifier Machines are used to create emulsions for drug delivery systems, ointments, and various specialty chemicals. The controlled emulsification process helps to improve the bioavailability, stability, and effectiveness of these products.

Choosing the Right Emulsifier Machine

Selecting the appropriate Emulsifier Machine for a specific application requires careful consideration of various factors, such as production volume, viscosity of the product, desired particle size, and the specific needs of the industry.

When choosing an Emulsifier Machine, it is essential to consult with experienced manufacturers and suppliers to ensure that the selected equipment meets the unique requirements of the application. They can provide guidance on the various machine types, their capabilities, and the most suitable configuration for the desired product.

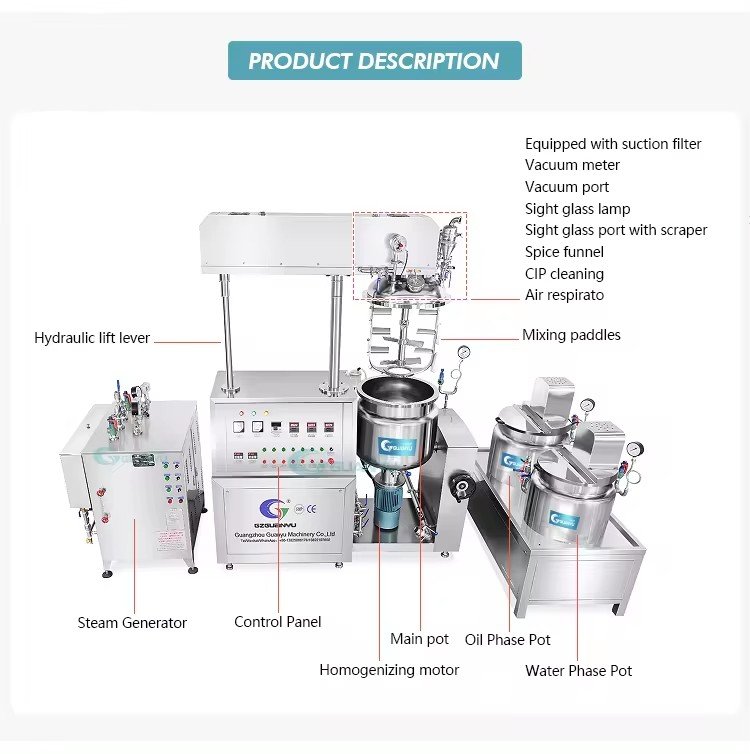

What are the different types of vacuum Emulsifier Machines?

Vacuum Emulsifier Machines are a specialized type of Emulsifier that operate under reduced atmospheric pressure. These machines are designed to create emulsions with reduced air content, resulting in products with improved stability, texture, and shelf-life.

Some common types of vacuum Emulsifier Machines include:

Vacuum homogenizers: These machines use a combination of high-speed rotor-stator assemblies and a vacuum system to create fine emulsions with minimal air incorporation.

Vacuum mixers: These machines employ slow-speed agitation under vacuum conditions to gently mix and emulsify ingredients, often used for high-viscosity products like creams and ointments.

Vacuum Emulsifier Machines with deaeration: These machines feature both high-shear emulsification and a vacuum system to remove air from the emulsion, producing a more stable and consistent product.

The choice of vacuum Emulsifier Machine will depend on the specific product requirements, desired emulsion characteristics, and the production volume.

Installation and Maintenance

Proper installation and maintenance of an Emulsifier Machine are crucial for ensuring its long-term performance and optimal product quality. Before installing the machine, it is essential to prepare the site, ensuring adequate space, utilities, and environmental controls are in place.

During the installation process, the Emulsifier Machine must be properly leveled, connected to power and utilities, and calibrated according to the manufacturer’s instructions. Thorough testing and validation should be conducted to ensure the machine is functioning as intended.

Ongoing maintenance of the Emulsifier Machine is also critical. This includes regular cleaning, inspection, and replacement of wear parts as per the manufacturer’s recommendations. Proper documentation and record-keeping of maintenance activities can help prevent unexpected breakdowns and ensure compliance with industry standards and regulations.

Regulatory Compliance and Safety

The use of Emulsifier Machines is subject to various industry standards and regulatory requirements, depending on the specific application and geographic location. Manufacturers and operators must ensure that their equipment and processes comply with relevant safety, quality, and environmental regulations.

Common industry certifications and standards for Emulsifier Machines include CE marking, FDA approval, and adherence to Good Manufacturing Practices (GMP) guidelines. Proper safety features, such as guards, emergency stops, and noise-reduction measures, must also be in place to protect operators and ensure a safe working environment.

Additionally, the disposal of waste generated during the emulsification process, as well as the environmental impact of the machine’s operation, should be carefully considered and addressed to minimize the ecological footprint of the manufacturing process.

Troubleshooting and Common Issues

Emulsifier Machines, like any complex machinery, can occasionally experience issues or malfunctions. Common problems may include inconsistent emulsion quality, excessive foaming, machine downtime, and wear or damage to internal components.

When troubleshooting an Emulsifier Machine, it is essential to follow a structured approach. This may involve reviewing operating parameters, inspecting for wear or damage, and consulting with the machine manufacturer or a qualified service technician. Maintaining detailed records of machine performance and any issues encountered can also aid in the diagnosis and resolution of problems.

Preventive maintenance, regular calibration, and adherence to best practices can help minimize the risk of common issues and ensure the long-term reliable operation of the Emulsifier Machine.

WOW just what I was searching for. Came here by searching for nordvpn coupons inspiresensation (92url.com) special coupon code

2024

Wonderful work! This is the kind of info that should be shared across the web.

Shame on the seek engines for no longer positioning this submit higher!

Come on over and consult with my web site . Thanks =)

My web-site Eharmony Special Coupon Code 2025

Hi there would you mind sharing which blog platform you’re using?

I’m planning to start my own blog soon but I’m having a difficult time deciding between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your design seems different

then most blogs and I’m looking for something completely unique.

P.S My apologies for getting off-topic but I had to ask!

Look into my webpage: vpn

It’s very easy to find out any topic on net as compared to books, as I found this piece of

writing at this web site. https://tinyurl.com/28555853 gamefly

These are actually fantastic ideas in about blogging.

You have touched some pleasant factors here. Any way keep up wrinting.

What is vpn connection https://tinyurl.com/2ytofo73

Generally I don’t learn post on blogs, however I would like to say that this write-up

very forced me to take a look at and do so! Your writing

taste has been amazed me. Thanks, very nice post.

Yes! Finally something about vpn.

These are in fact fantastic ideas in on the topic of blogging.

You have touched some fastidious things here. Any way keep up wrinting.

https://tinyurl.com/yneylc4d eharmony special coupon code 2025

When someone writes an piece of writing he/she maintains the plan of a user in his/her

mind that how a user can be aware of it. Therefore that’s

why this paragraph is amazing. Thanks! vpn https://www.highlandguides.com/