A fully automated production line for liquid cleaning products is a sophisticated system designed to streamline the entire manufacturing process, from raw material handling to final product packaging. This advanced setup not only enhances efficiency but also ensures consistent quality and compliance with industry standards. ในบทความนี้, we will delve deeper into each component of the production line, exploring its functions, ข้อดี, and the role it plays in producing high-quality liquid cleaning products.

pictures about Production Line for Liquid Cleaning Products

The first stage of production involves the careful handling and mixing of raw materials.

- Ingredient Storage Tanks: These tanks are essential for storing liquid raw materials, such as surfactants, ตัวทำละลาย, และน้ำหอม. They ensure that ingredients are readily available and properly maintained. Typically constructed from stainless steel, these tanks are designed to prevent contamination and facilitate easy cleaning.

- Mixing Tanks/Stirring Tanks: Once the raw materials are prepared, they are transferred to mixing tanks. These tanks are equipped with advanced mixing technology, often including agitators that create uniform blends. Heating and cooling jackets can be utilized to maintain optimal temperatures, which is vital for chemical reactions in formulations. The efficient mixing process is crucial for achieving the desired consistency and effectiveness of the cleaning products.

- Weighing Systems: Precision is critical in the production of liquid cleaning products. Weighing systems ensure that each ingredient is added in the correct amount. Automated scales with digital displays can be integrated into the system, allowing for real-time monitoring and adjustments, thereby minimizing waste and ensuring consistency in every batch.

2. Conveying Systems

Efficient transportation of materials between different stages of production is vital.

- Pipes and Pumps: High-quality pipes and pumps are used to transfer blended liquids to the filling machines. These systems must be designed to handle the viscosity and chemical properties of the liquids, preventing leaks and ensuring safety.

- Conveyor Belts: Conveyor systems play a crucial role in moving bottles or containers through various stages of production. They are designed to reduce manual handling and facilitate smooth transitions from one station to another, improving overall workflow efficiency.

3. Filling Equipment

The filling stage is where the product is packaged into its final containers.

- เครื่องบรรจุ: The choice of filling machine depends on the product’s characteristics and the required accuracy. Options include piston pump fillers for viscous liquids, peristaltic pump fillers for sensitive formulations, and gravity fillers for low-viscosity liquids. Each type of machine is designed to maximize efficiency while minimizing spillage and waste.

- Multi-Head Filling Systems: To enhance productivity, multi-head filling systems can be implemented. These systems allow multiple bottles to be filled simultaneously, significantly increasing the throughput and reducing cycle times.

4. Sealing Equipment

Once the bottles are filled, sealing is essential to ensure product integrity.

- Sealing Machines: Various sealing machines are employed to secure the tops of bottles. Options include capping machines that apply screw caps, crimping machines for metal closures, and foil sealing machines for tamper-proofing. Each sealing method is chosen based on the specific requirements of the product and packaging.

- Automatic Cap Sorters: These machines streamline the capping process by organizing and positioning caps automatically onto bottles. This automation minimizes labor costs and reduces the risk of human error during capping.

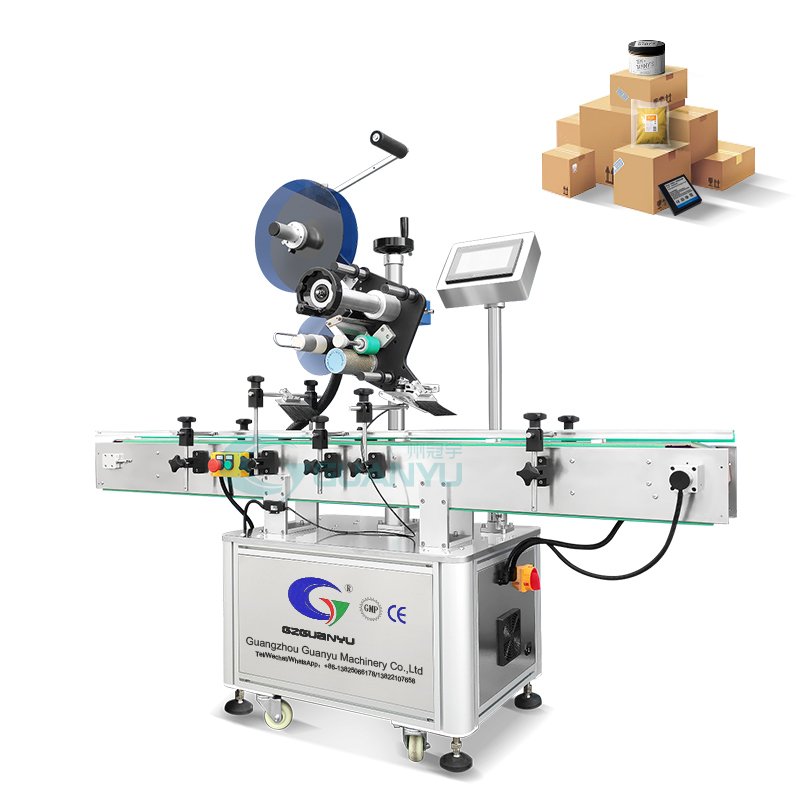

5. Labeling and Coding Equipment

Proper labeling and coding are crucial for compliance and branding.

- Labeling Machines: Automatic labeling machines apply labels to containers quickly and accurately. Different types of labeling machines are available, including those specifically designed for round bottles or flat containers. These machines ensure that labels are applied consistently and correctly, enhancing the product’s professional appearance.

- Coding Machines/Inkjet Printers: These devices print essential information, such as production dates, batch numbers, and expiration dates, directly onto the bottles. This coding is crucial for traceability and compliance with regulatory standards.

6. อุปกรณ์บรรจุภัณฑ์

After sealing and labeling, products need to be packaged for shipment.

- Shrink Wrapping Machines: Shrink wrapping machines apply plastic film around finished bottles, providing an additional layer of protection. This packaging method not only secures the product but also enhances shelf appeal.

- เครื่องบรรจุกล่อง: These machines automatically package individual bottles into cartons for distribution. This automated process improves efficiency and ensures that products are securely packaged for transport.

- Case Sealers: ในที่สุด, case sealers are employed to seal cardboard boxes containing multiple cartons of the product. This step is crucial for ensuring that products remain intact during shipping and handling.

7. Inspection Equipment

Quality control is an integral part of the production process.

- Level Detectors: These devices check the liquid levels in bottles to ensure they meet the specified requirements. Maintaining consistent fill levels is essential for product quality and customer satisfaction.

- Weight Check Machines: Automated weight check systems verify that each bottle contains the correct amount of product. This ensures compliance with regulatory standards and helps prevent financial losses due to underfilled containers.

- Visual Inspection Systems: These systems use cameras and sensors to inspect labels, แมวน้ำ, and overall bottle appearance. By identifying defects, manufacturers can maintain high-quality standards and avoid customer complaints.

8. อุปกรณ์เสริม

To support the production line, several auxiliary systems are needed.

- Air Compressors: Air compressors provide the necessary pneumatic power for various equipment in the production line, enhancing efficiency and reducing energy consumption.

- เหล็กกล้า (ทำความสะอาดสถานที่) Systems: Hygiene is paramount in the production of cleaning products. CIP systems facilitate the thorough cleaning of production line components without disassembling equipment, ensuring compliance with health and safety regulations.

บทสรุป

A fully automated production line for liquid cleaning products incorporates a wide range of specialized equipment designed to ensure efficiency, คุณภาพ, and safety throughout the manufacturing process. Each component, from raw material handling to final packaging, plays a critical role in delivering high-quality cleaning products to the market. This advanced system not only enhances productivity but also ensures consistency and compliance with industry standards, making it an essential setup for modern manufacturing facilities.

By leveraging technology and automation, manufacturers can meet increasing consumer demand while maintaining high standards of quality and safety. As industries continue to evolve, the integration of innovative solutions within the production line will be crucial in addressing future challenges and opportunities in the liquid cleaning products market.

Loto288. I am feeling lucky, so give it a shot. Maybe, just maybe, your numbers come up! loto288. Could change your life!

777jilipg is classic! Love the selection of Jili and PG games. Lots of familiar options, and that makes me happy. Give it a spin for sure! 777jilipg

คุณช่วยระบุเนื้อหาบทความของคุณให้เจาะจงมากขึ้นได้ไหม? หลังจากที่ได้อ่านมันแล้ว, ฉันยังคงมีข้อสงสัยอยู่บ้าง. หวังว่าคุณจะสามารถช่วยฉันได้.

บทความของคุณช่วยฉันได้มาก, มีเนื้อหาที่เกี่ยวข้องเพิ่มเติมอีกไหม? ขอบคุณ!