Регулярное техническое обслуживание смесителя предлагает наиболее эффективный способ сократить время простоя производства. Ты можешь повысить надежность и сэкономить деньги поддерживая миксеры в хорошем состоянии. Промышленные миксеры, обслуживаемые в хорошем состоянии, работают плавнее и служат дольше.. Ежедневное внимание поможет вам обнаружить проблемы на ранней стадии, что означает меньшее количество поломок и более безопасную работу. Записи о техническом обслуживании показать, что миксеры при регулярном уходе работают лучше и потребляют меньше энергии. Следуя четкому контрольному списку технического обслуживания миксера, вы помогаете вашему производству оставаться стабильным и избегать дорогостоящих сюрпризов.

Кончик: Простой, Проактивные действия с вашими миксерами приводят к меньшему количеству простоев и лучшим результатам каждый день.

Ключевые выводы

Регулярное техническое обслуживание миксера предотвращает поломки., сокращает время простоя, и обеспечивает бесперебойную работу производства.

Ежедневно, еженедельно, и ежемесячные проверки помогают выявить проблемы на ранней стадии и продлить срок службы ваших миксеров..

Проактивный уход, как чистка и смазка, улучшает производительность смесителя и снижает затраты на ремонт.

Обучение персонала и ведение подробного учета технического обслуживания повышают надежность и помогают избежать дорогостоящих ошибок..

Использование экспертной поддержки и защита смесителей от пыли и повреждений еще больше снижают риски простоя..

Причины простоя

Общие проблемы

Вы сталкиваетесь со многими проблемами, которые могут привести к простою миксера.. Некоторые проблемы часто возникают в промышленных условиях.. Если вы знаете, что искать, вы можете предотвратить непредвиденные поломки и обеспечить бесперебойную работу вашего производства.

Механические проблемы, такие как несоосность вала вызывает вибрацию или скрежетание.

Посторонние предметы или неправильное расположение мешалки повреждают компоненты смесителя..

Засоренные вентиляционные отверстия приводят к проблемам с воздушным потоком и скоплению пыли., что может увеличить риск возникновения пожара.

Электрические проблемы, например, обрыв шнуров или изменение тока, сигнализировать о неисправностях в системе.

Износ коробки передач, уплотнение утечки, и коррозия резервуаров может привести к утечкам и загрязнению.

Износ лезвий снижает эффективность смешивания и может повлиять на качество продукта..

Необычные шумы часто означают износ подшипников или несоосность..

Чрезмерная вибрация может возникнуть из-за незакрепленных или изношенных деталей..

Изменения скорости могут быть результатом неисправных регуляторов скорости или двигателей..

Вы также можете увидеть такие проблемы, как неадекватное смешивание, загрязнение, или масштабирование. Эти проблемы снижают теплопередачу и производительность смешивания.. Если вы не часто чистите и проверяете свои миксеры, вы рискуете увеличить время простоя.

Вот таблица, в которой показаны некоторые распространенные причины., симптомы, и решения:

Общая причина | Симптомы | Превентивные меры/решения |

|---|---|---|

Недостаточное эмульгирование | Непоследовательная текстура, разделение фаз | Осмотрите и замените ротор-статор.; калибровать двигатель |

Сбой циркуляции насоса | Возврата товара нет, перегрев | Чистые трубопроводы; заменить уплотнения |

Чрезмерная вибрация или шум | Необычные шумы, вибрация | Выровняйте вал; безопасные крепления; заменить подшипники |

Перегрев | Неожиданные остановки, термовыключатели | Обеспечьте охлаждение; установить термодатчики |

Частые механические простои | Регулярные сбои, несовместимые циклы | Профилактическое обслуживание; обучение персонала |

Влияние плохого обслуживания

Плохое обслуживание приводит к увеличению простоев и снижению производительности.. Когда вы пропускаете регулярный уход, ваш миксер становится менее надежным. Вы тратите больше времени на решение проблем и меньше времени на создание. Это снижает доступность и производительность вашего оборудования..

Если ваш миксер работает медленнее или производит больше бракованных продуктов, общая эффективность вашего оборудования (ОЕЕ) капли. Например, если вы планируете проработать миксер восемь часов, но потеряете два часа на ремонт, время простоя увеличивается, а OEE падает. Вы также используете больше энергии и рискуете больше поломок.. Через некоторое время, плохое обслуживание может привести к увеличению затрат и снижению качества продукции..

Примечание: Регулярное техническое обслуживание поможет избежать простоев, уменьшить непредвиденные поломки, и пусть ваши микшеры работают наилучшим образом.

Сокращение времени простоя производства

Преимущества профилактического ухода

Вы можете сократить время простоя производства, приняв упреждающий подход к техническому обслуживанию миксера.. Когда вы действуете до того, как начнутся проблемы, вы обеспечиваете бесперебойную работу вашего оборудования и избегаете неожиданных остановок. Исследование McKinsey & Компания показывает, что структурированные программы технического обслуживания могут сократить время простоя оборудования до 50%. Это означает, что вы тратите меньше времени на устранение проблем и больше внимания уделяете эффективности производства..

Проактивный уход направлен на устранение коренных причин неисправности смесителя.. Вы не просто устраняете проблемы по мере их появления — вы предотвращаете их возникновение.. Многие отраслевые тематические исследования подчеркивают преимущества этого подхода.:

Вы устраняете основные причины выхода из строя оборудования, что помогает сократить время простоев и повысить долгосрочную надежность.

Регулярная очистка и проверка миксера предотвращает загрязнение и обеспечивает максимальную работу всех частей..

Передовые системы, как мониторинг состояния, поможет вам обнаружить неисправности на ранней стадии и даже позволит проводить удаленные проверки в сложных условиях.

Вы можете лучше планировать техническое обслуживание, а это значит меньше сюрпризов и меньше сбоев в вашем производственном графике.

Сочетание профилактического и профилактического обслуживания приводит к повышению производительности и уменьшению количества поломок..

Когда вы часто обслуживаете миксер, вы сокращаете время незапланированных простоев и обеспечиваете бесперебойную работу вашей производственной линии. Частый, хорошо спланированное техническое обслуживание также помогает вам находить закономерности в событиях простоя, чтобы вы могли предотвратить их повторение. Ваша команда становится более опытной в обнаружении проблем, что повышает общую производительность и надежность.

Преимущества стоимости и качества

Профилактическое обслуживание миксера не только сокращает время простоя. Это также помогает вам контролировать затраты и обеспечивать стабильное качество продукции.. В таблице ниже показано, как различные действия по техническому обслуживанию способствуют достижению ваших целей.:

Аспект технического обслуживания | Вклад в снижение затрат и стабильность качества |

|---|---|

Регулярное обслуживание оборудования | Предотвращает поломки, продлевает срок службы оборудования, снижает частоту замены, и обеспечивает соблюдение стандартов. |

Смазка, Калибровка, Инспекция | Уменьшает трение и снижение производительности, что приводит к экономии энергии и минимизации непредвиденных простоев. |

Очистка | Удаляет остатки, ухудшающие производительность, повышение эффективности. |

Острота лезвия и своевременная замена | Поддерживает эффективную обработку, уменьшает трение и время обработки, напрямую влияет на качество и стабильность продукта. |

Проактивная замена изношенных деталей | Предотвращает вторичное повреждение, поддерживает эффективность оборудования, сокращает время незапланированных простоев, и продлевает срок службы оборудования. |

Вы можете видеть, что каждый шаг вашего Регулярное техническое обслуживание помогает сократить время простоя производства и поддерживайте оптимальную производительность вашего микшера. Инструменты мониторинга и прогнозирования в реальном времени позволяют выявить проблемы на ранней стадии., что снижает затраты на ремонт и обеспечивает целостность вашей продукции. Когда вы сокращаете время простоя, вы также повышаете эффективность производства и достигаете поставленных целей с меньшими задержками..

Профилактическое обслуживание миксера

Вы можете сократить время простоя и обеспечить бесперебойную работу вашего оборудования, соблюдая план профилактического обслуживания миксера.. Регулярный график технического обслуживания поможет вам выявить проблемы на ранней стадии и избежать дорогостоящего ремонта.. Когда вы используете контрольный список обслуживания миксера, вы следите за тем, чтобы каждый важный шаг был выполнен. В этом разделе вы ежедневно получаете, еженедельно, и ежемесячные советы по техническому обслуживанию, которые помогут вам оптимизировать смеситель сухих ингредиентов и другие типы смесителей на вашем предприятии..

Советы по ежедневному обслуживанию

Ежедневный уход – основа профилактического обслуживания смесителя.. Всегда следует начинать и заканчивать смену быстрой проверкой и чисткой.. Это сохраняет миксер сухих ингредиентов в отличной форме и предотвращает накопление остатков..

Ежедневный контрольный список:

Очищайте и дезинфицируйте все детали, контактирующие с пищевыми продуктами, после каждого использования.. Это предотвращает образование остатков и загрязнений..

Проверьте смеситель на наличие трещин., ржавчина, или износ смесительных рычагов и насадок.

Немедленно решайте любые обнаруженные проблемы, чтобы предотвратить дальнейший ущерб..

Затяните все ослабленные винты или болты..

Храните миксер в чистом, сухое место вдали от влаги и солнечных лучей.

Удаление пыли и мусора снаружи и внутри..

Осмотрите навесное оборудование на наличие повреждений и замените при необходимости..

Кончик: Тщательно очищайте миксер каждый день.. Этот простой шаг предотвращает большинство распространенных проблем и обеспечивает эффективную работу объемных миксеров..

Советы по еженедельному обслуживанию

Еженедельное плановое обслуживание — это нечто большее, чем ежедневные проверки.. Вам следует обратить внимание на признаки износа и убедиться, что все движущиеся части работают плавно.. Это помогает продлить срок службы ваших объемных миксеров и обеспечивает стабильность вашей производственной линии..

Еженедельный контрольный список:

Выполните визуальный осмотр всех внешних компонентов., включая двигатели, валы, и лезвия.

Затяните все незакрепленные детали и замените изношенные детали..

Очистите миксер изнутри и снаружи, используя подходящие чистящие инструменты.. Оборудование с цветовой маркировкой помогает предотвратить перекрестное загрязнение..

Смажьте все движущиеся части рекомендованной смазкой..

Проверьте уплотнения на предмет утечек или хрупкости и при необходимости замените их..

Проверьте соосность вала, чтобы предотвратить изгиб или деформацию..

Осмотрите приводные ремни и коробки передач на наличие трещин и потертостей..

Осмотрите лопасти и рабочие колеса на наличие стружки., изгибы, или коррозия.

Заменяйте масло в соответствии с рекомендациями, чтобы движущиеся детали оставались холодными и гладкими..

Проверьте навесное оборудование, такое как мешалки и скребки, на наличие повреждений..

Уровни производительности тестов, включая контроль скорости и температуры.

Контролируйте уровни вибрации, чтобы выявить дисбаланс или несоосность.

Осмотр электрических компонентов, включая проводку и двигатели.

Проверьте функции безопасности, такие как аварийное отключение и блокировки..

Отрегулируйте настройки скорости, чтобы оптимизировать миксер сухих ингредиентов и предотвратить плохое перемешивание..

Примечание: Ведите учет всех еженедельных работ по техническому обслуживанию. Это поможет вам отслеживать проблемы и планировать будущее профилактическое обслуживание..

Советы по ежемесячному обслуживанию

Ежемесячное плановое техническое обслуживание направлено на более глубокие проверки и долгосрочный уход.. Вы можете обнаружить ранние признаки износа или неисправности и принять меры до того, как проблемы возникнут..

Ежемесячный контрольный список:

Следите за движущимися частями, такими как мешалки и мешалки, на предмет чрезмерного износа..

Смажьте все движущиеся части в соответствии с инструкциями производителя..

Проверьте несоосность мешалок или миксеров..

Осмотр уплотнений и прокладок на наличие трещин., утечки, или носить.

Немедленно замените поврежденные уплотнения и прокладки..

Обеспечьте правильное выравнивание во время всех проверок..

Документируйте любые необычные результаты, чтобы помочь спланировать будущее обслуживание..

Проверьте выравнивание смесителя и проверьте прямолинейность вала..

Осмотрите крыльчатки на наличие сколов., питтинг, или трещины в сварных швах.

Просмотрите записи о техническом обслуживании, чтобы выявить закономерности и улучшить план текущего обслуживания..

Вызывать: Ежемесячные проверки помогут выявить скрытые проблемы в объемных миксерах и смесителях сухих ингредиентов до того, как они приведут к простою..

Стол: Руководство по периодичности технического обслуживания миксера

Задача | Ежедневно | Еженедельно | Ежемесячно |

|---|---|---|---|

Очистить и продезинфицировать | ✔ | ✔ | ✔ |

Визуальный осмотр | ✔ | ✔ | ✔ |

Затяните болты и винты | ✔ | ✔ | ✔ |

Смазка | ✔ | ✔ | |

Проверьте уровень масла | ✔ | ✔ | ✔ |

Осмотр уплотнений и прокладок | ✔ | ✔ | |

Осмотр лезвий и насадок | ✔ | ✔ | ✔ |

Проверьте функции безопасности | ✔ | ✔ | |

Контролируйте вибрацию и выравнивание | ✔ | ✔ | |

Просмотр записей технического обслуживания | ✔ |

Вы всегда должны следовать графику регулярного технического обслуживания, который соответствует вашим производственным потребностям.. Высокообъемные среды, например, те, которые используют объемные миксеры, требуют строгой гигиены и документации. Очистка на месте (Прозрачный) системы, методы сухой чистки, и электростатическое распыление могут помочь поддерживать гигиену миксера и предотвратить загрязнение.. Программы обучения сотрудников и гигиены рук также играют большую роль в обеспечении безопасности и надежности ваших миксеров..

Дополнительные советы по уходу за миксером: Никогда не перегружайте миксер. Используйте правильные насадки для каждой работы. Храните смеситель сухих ингредиентов и объемные миксеры под защитными крышками, защищающими их от пыли и влаги..

Следуя этим шагам по профилактическому техническому обслуживанию миксера,, вы можете сократить время простоя, продлить срок службы оборудования, и обеспечить бесперебойную работу вашего производства.

Советы по обслуживанию компонентов

Поддержание каждой части вашего миксера в отличном состоянии поможет вам избежать простоев и получить наилучшие результаты от вашего оборудования.. Вам нужно сосредоточиться на тюленях, подшипники, ремни, лезвия, электрические системы, и коробки передач. Эти советы по техническому обслуживанию помогут вам продлить срок службы миксера и обеспечить бесперебойную работу производственной линии..

Уплотнения и подшипники

Уплотнения и подшипники защищают смеситель от утечек и механических повреждений.. Если вы позаботитесь об этих частях, вы можете предотвратить многие распространенные проблемы с промышленными и объемными миксерами.

Установите уплотнения с точное выравнивание и правильная посадка. Этот шаг предотвращает ранние сбои.

Выбирайте уплотнения, изготовленные из материалов, соответствующих вашей технологической жидкости и условиям эксплуатации.. Это уменьшает химический износ.

Осмотр уплотнений и подшипников на наличие трещин., носить, или смещение во время планового технического обслуживания.

Используйте тепловизионный анализ и анализ вибрации, чтобы выявить скрытые проблемы, не останавливая миксер..

Избегайте сухого хода. Всегда заливайте систему перед запуском, чтобы предотвратить перегрев и повреждение от трения..

Немедленно устраняйте вибрацию и дисбаланс, чтобы защитить уплотнения и подшипники..

Обучите свою команду правильным методам установки и обслуживания..

Содержите уплотнения в чистоте и заменяйте уплотнительные кольца или эластомеры, если вы видите затвердевание или трещины..

Поддерживайте правильную смазку для уменьшения трения и перегрева.

Следить за давлением и температурой оставаться в безопасных пределах.

Документируйте все работы по техническому обслуживанию и планируйте регулярные проверки..

Кончик: Выполнение этих шагов может уменьшить утечки и механические неисправности., помогая вам получить больше от смесителя сухих ингредиентов и объемных миксеров.

Ремни и приводные системы

Ремни и приводные системы передают мощность миксера. Если вы проверите и замените их вовремя, вы поддерживаете работу микшера с оптимальной производительностью.

Задача обслуживания | Частота |

|---|---|

Ежемесячно | |

Замена ремня | Каждый 10 годы (зависит от использования/модели) |

Смазка движущихся частей | Еженедельно |

Глубокая очистка | Ежеквартальный |

Проверка электрических частей | Ежемесячно |

Осмотрите ремни на наличие трещин, изнашивание, или признаки износа каждый месяц.

Заменяйте ремни примерно каждые 10 годы, или раньше, если вы видите повреждения.

Смазывайте движущиеся части еженедельно, чтобы предотвратить трение и износ..

Глубоко очищайте системы привода каждый квартал, чтобы удалить пыль и мусор..

Проверьте соосность ремней и шкивов, чтобы избежать неравномерного износа..

Ведите учет всех замен и проверок ремней в рамках планового технического обслуживания..

Примечание: Регулярные проверки и своевременная замена ремней помогают объемным миксерам и смесителям сухих ингредиентов работать без перебоев..

Лезвия и мешалки

Лопасти и мешалки выполняют тяжелую работу в вашем миксере.. Часто очищайте и проверяйте их, чтобы обеспечить эффективность миксера сухих ингредиентов и объемных миксеров..

Удаляйте остатки материала с лезвий и барабана после каждого использования..

Промойте внутреннюю часть барабана и ножи водой, чтобы удалить мусор..

Используйте чистящий раствор (коммерческое средство или смесь воды и мягкого моющего средства) чтобы смягчить прилипший материал.

Пусть решение постоит 10-15 минуты.

Почистите лезвия и барабан жесткой щеткой., сосредоточение внимания на трудных местах.

Для жесткого наращивания, осторожно используйте долото или скребок.

Промойте все чистой водой.

Полностью высушите все детали, особенно стыки и щели.

Смажьте движущиеся части, такие как барабанные ролики и подшипники, после очистки..

Надежно соберите все снятые детали..

Храните миксер в сухом, крытое место, чтобы защитить его от повреждений.

Вызывать: Очищайте лезвия и мешалки после каждого использования.. Эта простая привычка обеспечивает бесперебойную и безопасную работу миксера для сухих ингредиентов и объемных миксеров..

Электрика и батареи

Безопасная и надежная электрическая система обеспечивает работу вашего миксера.. Вам необходимо часто проверять батареи и электрические детали..

Осмотр аккумуляторов и клемм на предмет коррозии.. Убедитесь, что все соединения затянуты.

Тестовые переключатели, огни, и контроль, чтобы подтвердить, что они работают.

Проверьте кнопки аварийной остановки и элементы управления безопасностью. для правильной работы.

Найдите поврежденные провода и проверьте сопротивление заземления..

Очистите электрические панели и соединения от пыли и мусора..

Проверьте электрическую систему, чтобы убедиться, что она соответствует стандартам производительности..

Проверьте напряжение аккумулятора и очистите клеммы в рамках планового технического обслуживания..

Тревога: Всегда отключайте питание перед работой с электрическими деталями.. Этот шаг обеспечит вашу безопасность.

Редукторы и смазка

Редукторы передают мощность и обеспечивают движение миксера. Хорошая смазка и регулярные проверки предотвращают преждевременный износ и поломки..

Меняйте масло после первого 500 часов или 4 недели использования.

После этого, менять масло каждые 2500 часа или каждые 6 месяцы.

Если температура масла превышает 150°F, меняйте масло чаще.

Используйте систему циркуляционного смазочного масла, если температура масла превышает 200°F..

Контролируйте состояние масла, проверяя цвет, толщина, и для любого мусора.

Используйте только смазочные материалы, одобренные производителем коробки передач..

Не смешивайте разные смазки.

Храните смазочные материалы в чистом, сухое место.

Осмотр уплотнений, передышки, муфты, и подшипники на износ.

Используйте инструменты для контроля температуры масла, уровень, вибрация, и шум.

Ведите подробный учет всех работ по смазке и техническому обслуживанию..

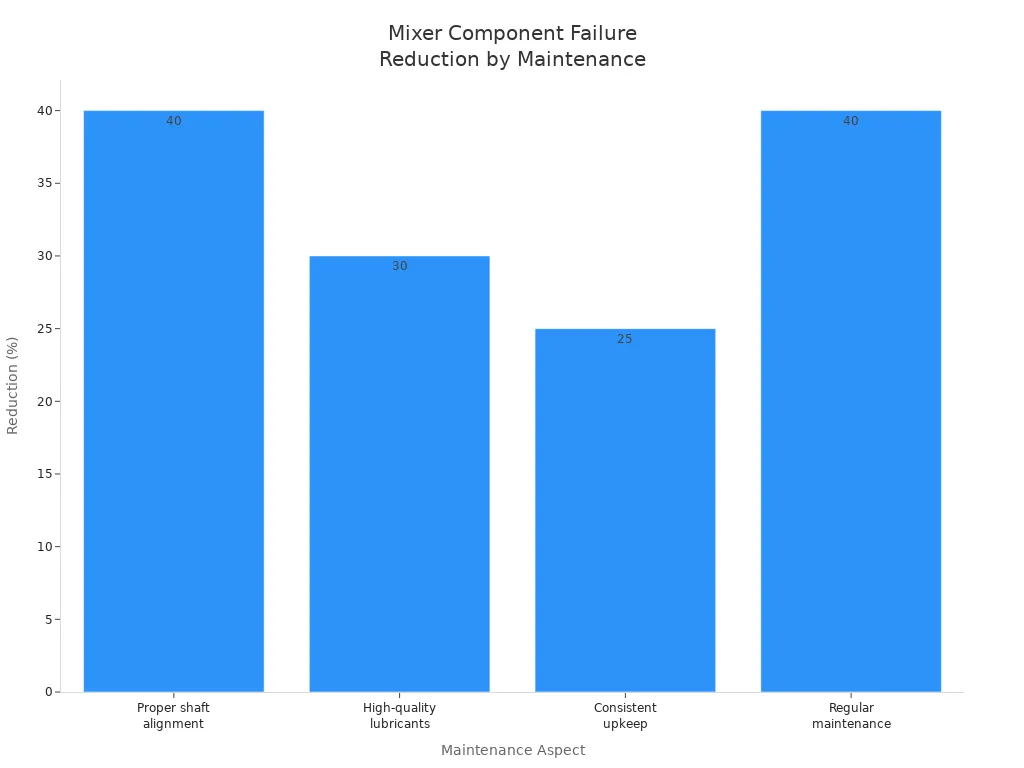

Кончик: Использование высококачественных смазочных материалов и соблюдение установленного графика может уменьшить износ до 30% и снизить риск поломок.

Регулярное техническое обслуживание и технологии прогнозирования помогают обнаружить проблемы до того, как они приведут к простою.. Датчики могут отслеживать вибрацию, температура, и качество масла в реальном времени. Такой подход позволяет планировать ремонт тогда, когда это лучше всего подходит для вашего производства., не тогда, когда случается поломка. Прогностическое обслуживание может сократить поломки на 70% и снизить затраты на 25%. Вы храните свои миксеры, включая смесители сухих ингредиентов и объемные смесители, бегают в своих лучших проявлениях.

Советы по обслуживанию: Придерживайтесь графика производителя для каждой детали.. Эта привычка может снизить риск отказа компонентов почти на 40% и сократить время простоя вдвое. Вы продлите срок службы миксера и сохраните надежность производственной линии..

Рекомендации по сокращению времени простоя

Обучение персонала

Вы можете сократить время простоев, инвестируя в обучение персонала.. Когда ты обучить операторов правильному использованию миксера, вы снижаете риск простоев и аварий. Хорошо обученный персонал рано выявляет проблемы и быстро реагирует в чрезвычайных ситуациях.. Вам следует перенимать знания от опытных работников прежде чем они уйдут на пенсию. Научите свою команду выравнивать оборудование и использовать правильную смазку.. Сосредоточьтесь на навыках устранения неполадок, чтобы ваши сотрудники могли устранять мелкие проблемы, не дожидаясь помощи извне.. Объедините практическую практику с уроками в классе, чтобы развить как практические, так и теоретические навыки.. Регулярное обучение позволяет всем быть в курсе последних событий и помогает избежать простоев, вызванных человеческим фактором..

Кончик: Используйте контрольные списки и курсы повышения квалификации, чтобы оттачивать навыки технического обслуживания., особенно для задач, которые случаются не часто.

Записи о техническом обслуживании

Хранение подробные записи технического обслуживания помогает выявить закономерности и повторяющиеся проблемы с микшером. Когда вы регистрируете каждый ремонт и проверку, вы создаете историю, показывающую причины простоев. Вы можете использовать эту информацию, чтобы скорректировать свой план обслуживания и запланировать техническое обслуживание до того, как возникнут проблемы.. Хорошие записи также помогут вам управлять запасными частями и соблюдать стандарты безопасности.. Например, производитель продуктов питания увеличил время безотказной работы, просматривая журналы и планируя капитальный ремонт до того, как возникнут поломки.

Отслеживайте все ремонты, инспекции, и замена деталей.

Регулярно просматривайте записи, чтобы выявить тенденции..

Используйте данные для планирования будущего обслуживания и сокращения времени простоя.

Экспертная поддержка

Консультации специалистов по обслуживанию смесителей дает вам доступ к расширенным стратегиям устранения неполадок и профилактическим мерам.. Эксперты предлагают аудиты и индивидуальные планы, которые помогут вашему оборудованию работать с максимальной эффективностью.. Они могут обучить ваш персонал, выполнить ремонт на месте, и предлагать обновления. Эта поддержка поможет вам избежать экстренных вызовов и незапланированных простоев.. Квалифицированные специалисты также повышают безопасность, своевременно обнаруживая опасности и продлевая срок службы вашего миксера..

Получите единый источник технической поддержки и обслуживания.

Используйте профилактические программы для сокращения времени простоя и затрат..

Положитесь на советы экспертов при обновлении и обеспечении соответствия требованиям..

Охрана окружающей среды

Защита миксера от пыли и мусора сокращает время простоя и повышает безопасность.. Использовать пылезащитные крышки и герметичные бункеры чтобы пыль не попадала в воздух. Регулярно очищайте миксер и рабочую зону с помощью нестатические метлы и заземленные контейнеры. Установите системы пылеулавливания для улавливания частиц, находящихся в воздухе.. Когда моешь оборудование, выключите питание и избегайте распыления воды на чувствительные детали.. Системы взрывоподавления и сертифицированное оборудование, нравиться Смесители ATEX или IECEx, добавить еще один уровень защиты в рискованных средах.

Плановое техническое обслуживание в непиковые часы во избежание срыва производства.

Используйте интеллектуальные системы мониторинга, чтобы предсказать, когда ваш микшер потребует внимания..

Содержите свое рабочее место в чистоте, чтобы ограничить скопление пыли и снизить риски..

Примечание: Экологический контроль и интеллектуальное планирование помогают сократить время простоев и обеспечить безопасность и надежность миксера..

Вы можете сократить время простоя производства, сделав обслуживание миксера ежедневной привычкой.. Когда вы следуете чек-листу и тренируете свою команду, вы видите меньше поломок и лучшие результаты. Учреждения, ориентированные на регулярный уход за миксером поддерживать свои миксеры в рабочем состоянии на протяжении десятилетий, экономить деньги, и повысить эффективность.

Часто смазывайте движущиеся части и проверяйте соосность..

Отслеживайте ключевые показатели эффективности, такие как OEE и среднее время восстановления чтобы измерить успех.

Начните сегодня и наблюдайте, как сокращается время простоя и повышается качество вашей продукции..

Часто задаваемые вопросы

Как часто нужно чистить миксер?

Вы должны чистить миксер после каждого использования.. Ежедневная очистка предотвращает накопление остатков и обеспечивает безопасность вашего оборудования.. Регулярная очистка помогает избежать загрязнения и обеспечивает бесперебойную работу производственной линии..

Какие признаки указывают на то, что ваш миксер нуждается в обслуживании??

Ищите странные звуки, вибрация, утечки, или медленное перемешивание. Эти признаки означают, что ваш миксер требует внимания. Быстрые действия помогут вам предотвратить простои и обеспечить правильную работу вашего оборудования..

Можно ли сократить время простоя с помощью простых проверок??

Да. Вы можете сократить время простоя, проверяя уровень масла., стяжные болты, и проверяем лезвия каждый день. Эти простые шаги помогут вам выявить проблемы на ранней стадии и поддерживать миксер в хорошем состоянии..

Почему важно обучение персонала для обслуживания миксера?

Обучение персонала научит вашу команду выявлять проблемы и быстро их устранять.. Обученные работники помогут вам избежать ошибок и обеспечить безопасную работу миксера.. Хорошая подготовка приводит к меньшему количеству поломок.

Какие записи следует вести при обслуживании миксера?

Ведите журнал всех ремонтов, инспекции, и замена деталей. Используйте таблицы для отслеживания дат и действий. Хорошие записи помогут вам спланировать будущее техническое обслуживание и сократить время простоев..

**хранилище разума**

Mind Vault — это формула когнитивной поддержки премиум-класса, созданная для взрослых. 45+. Он тщательно разработан, чтобы помочь сохранить ясное мышление.

**гл про**

гл про это натуральная пищевая добавка, предназначенная для поддержания сбалансированного уровня сахара в крови и снижения тяги к сладкому..

**дышать**

дышать — это настойка на растительной основе, созданная для улучшения работы легких и улучшения качества дыхания..

Я не думаю, что название вашей статьи соответствует содержанию, лол.. Просто шучу, главным образом потому, что у меня возникли некоторые сомнения после прочтения статьи.

SVV388211, now that’s a mouthful! Wonder what makes them different from the original SVV388? Gotta investigate! Check out svv388211

Heard some good things about xbet100. Thinking of giving it a shot. Anyone have any experiences? I’m curious and a little excited. Find out at xbet100