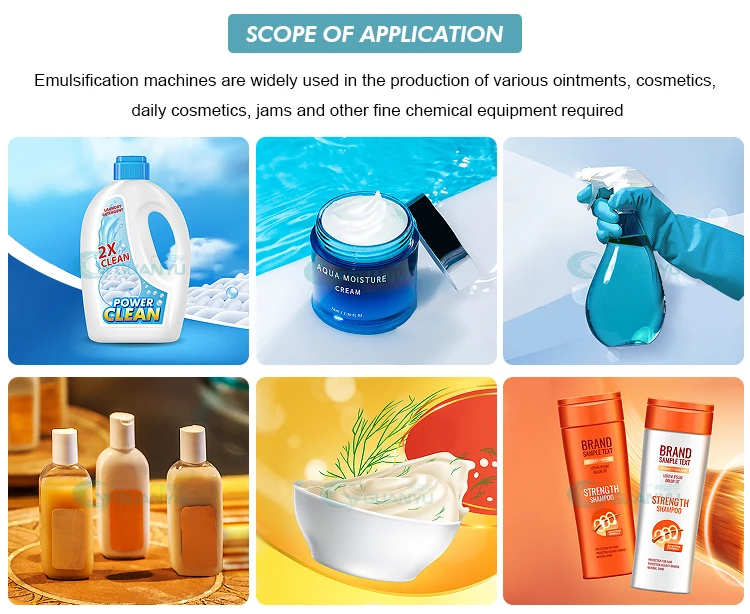

Вакуумная эмульгирующая машина, вакуумный гомогенизирующий эмульгирующий блендер, смеситель для косметического крема , крем для кожи,лосьон

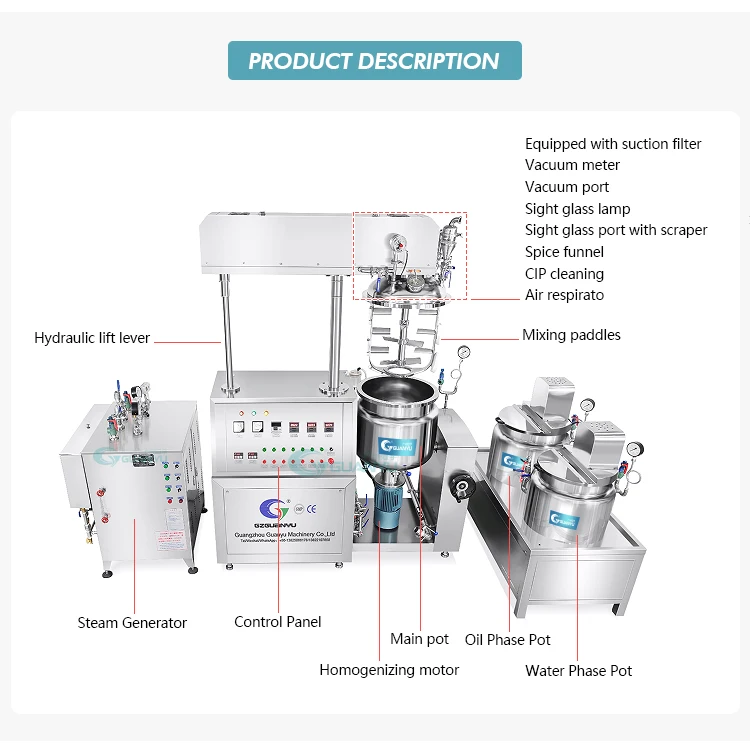

Описание продукции

Смешивающая лопасть

Регулирование скорости переменной частоты составляет 0-62R/мин, так что разные материалы можно смешать равномерно. Форма смешанного весла будет спроектирована в соответствии с вашими материалами

Гомогенизатор

Регламент скорости преобразования частоты 0-3200R/мин, однородная режущая головка для высокоскоростной резки материалов, так, чтобы материалы полностью разбились и перемешались!

Обогрев

Электрический нагрев или пара -нагревание может быть выбрано, и материал нагревается через межслойщик для достижения идеала

состояние перемешивания и эмульгирования.

состояние перемешивания и эмульгирования.

Масляно-водяной горшок

Резервуар для водной фазы и нефтяной фазовой резервуары предварительной системы предварительно разогревают и рассеивают сырье, затем вырваться

их до главного танка, и начать однородное смешивание, чтобы эмульгировать материалы

их до главного танка, и начать однородное смешивание, чтобы эмульгировать материалы

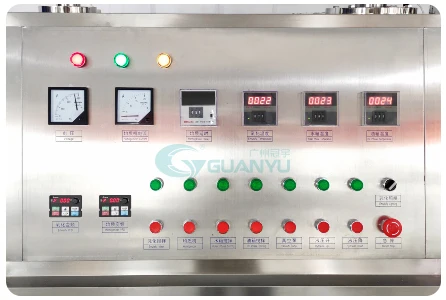

Консоль

Компания управления включает в себя настройки, такие как однородная сдвиг, Смешивание скорости конверсии частоты смешивание,

Рабочая время, экстракция вакуума, Межслойное отопление, и т. д..

(Управление ПЛК необязательно)

Рабочая время, экстракция вакуума, Межслойное отопление, и т. д..

(Управление ПЛК необязательно)

Услуга

Используйте компоненты всемирно известных брендов, чтобы обеспечить качество оборудования и более длительный срок службы.

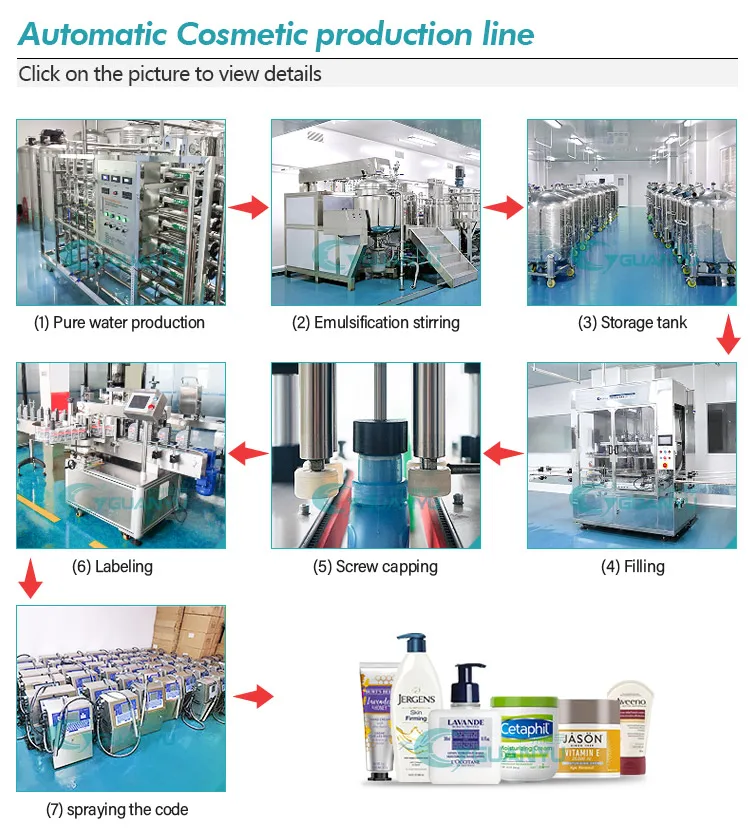

The Industrial Cosmetic Mixer Composition:Vacuum Homogenizer emulsifying mixer machine Vacuum Homogenizer emulsifying mixer machine is mainly composed of water pot,Масляная банка,emulsifying pot, вакуумная система, lifting system(необязательный) ,electric control system(PLC is optional) and operation platform, etc.Vacuum Homogenizer Usage and Application:Our industrial food mixer is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, foodindustry, краска и чернила, нанометровые материалы, нефтехимическая промышленность, printing and rubber, electrics and electronics and finechemical industry etc., the emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Отзывы

Пока нет отзывов.