Стандартная машина для изготовления жидкого мыла для ванн, косметический лосьон, крем-гель, паста, емкость для перемешивания, промышленное смесительное оборудование

Конфигурация продукта

Название элемента | Стандартная машина для изготовления жидкого мыла для ванн, косметический лосьон, крем-гель, паста, емкость для перемешивания, промышленное смесительное оборудование |

Пункт №. | Тренажерный зал-2000 |

Материал | SUS316L/SUS304 |

Гарантийная служба | 1 год |

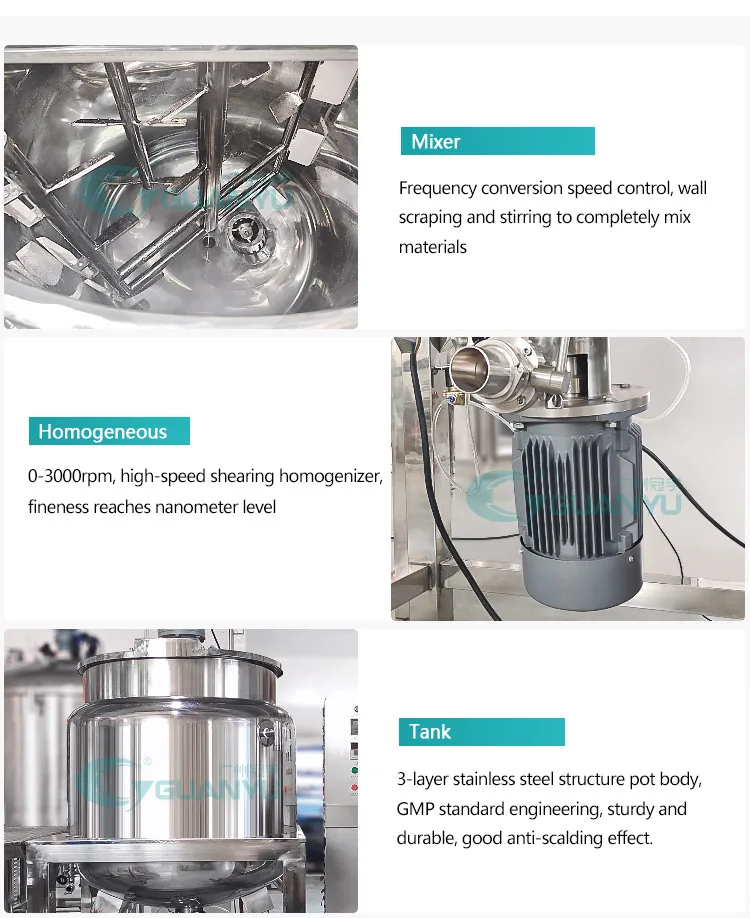

Метод смешивания | В одну сторону (двунаправленный) рассеяние типа рамы скребки |

Гомогенный режим | Нижняя циркуляция |

Открытие пути | Боковая циркуляция |

Несущий | С японским НСК |

Уплотнения | С Германией Бергман |

Параметры перемешивания | With Siemens Motor 7.5KW,Mitsubishi Inverter, Скорость 0-63 преподобный / мин |

Однородные параметры | With Siemens Motor 15-18.5KW,Mitsubishi Inverter, Скорость 0-3600 преподобный / мин |

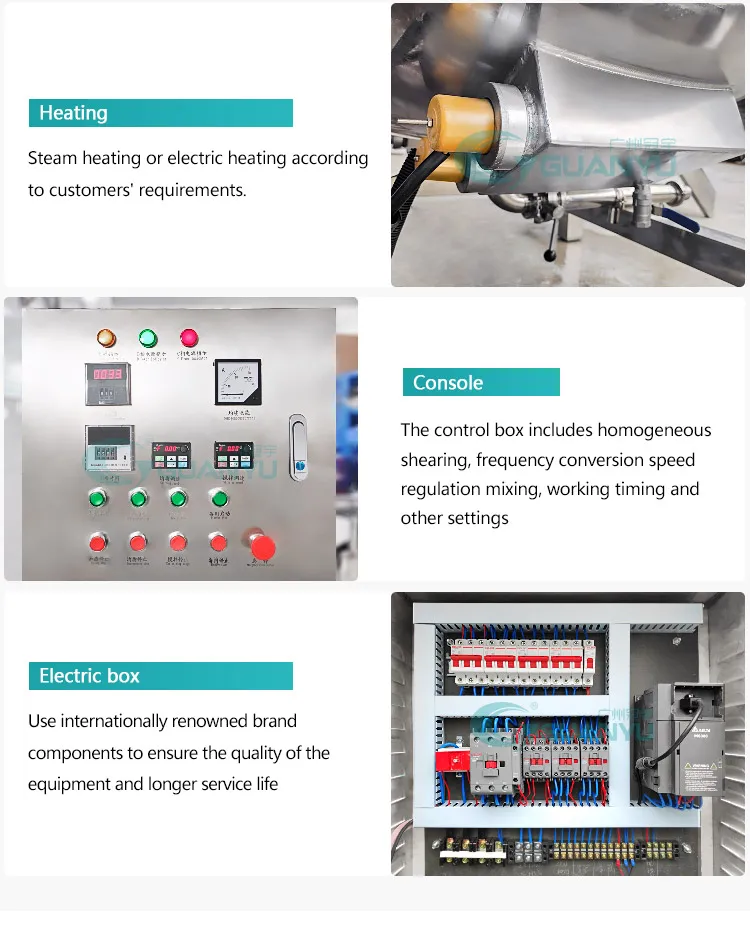

Электрические компоненты | Электрический / Паровое отопление |

Метод отопления | Электрическое/паровое отопление |

1. Эта компания производит вакуумные эмульгирующие сорта разнообразны, в том числе однородные точки системы на однородные под однородными, как внутри, так и внешней циркуляции однородной, система смешивания и двусторонняя перемешивание одностороннего движения, лента перемешивает;Система подъема разделена на одноцилиндровый и двойной цилиндр, и может быть настроен по запросу клиента.

2. Тройное смешивание. Управление скоростью преобразователя импортируемой частоты, может соответствовать различным требованиям процесса;

3. Гомогенная структура немецких технологий, Использование импортированного эффекта двойного механического уплотнения, Эмульгирующая скорость может достигать 4200 об/мин, Наибольшая максимальная тонкость сдвига может достичь 0.2 5 один;

4. Вакуумная деаэрация для достижения асептических требований, и использует вакуумные материалы, Особенно для порошкового материала с использованием вакуумного всасывания, чтобы избежать плавания пыли в небе;

5. Главный горшок может выбрать подъемное устройство, удобная очистка, Эффект очистки более значитель, корпус горшка может выбрать сброс разрядов;

6. Корпус горшка принял три слоя импорта сварки пластины из нержавеющей стали, резервуары и трубопроводы для полировки зеркала, Полное соблюдение требований GMP;

7. В соответствии с технологическими требованиями, нагревание и охлаждающий материал резервуара, пара и электрический нагрев два метода нагрева в основном включают в себя;

8. Для обеспечения более стабильного управления машиной стабильно, Использование импортных электрических приборов, может полностью соответствовать международным стандартам;

2. Тройное смешивание. Управление скоростью преобразователя импортируемой частоты, может соответствовать различным требованиям процесса;

3. Гомогенная структура немецких технологий, Использование импортированного эффекта двойного механического уплотнения, Эмульгирующая скорость может достигать 4200 об/мин, Наибольшая максимальная тонкость сдвига может достичь 0.2 5 один;

4. Вакуумная деаэрация для достижения асептических требований, и использует вакуумные материалы, Особенно для порошкового материала с использованием вакуумного всасывания, чтобы избежать плавания пыли в небе;

5. Главный горшок может выбрать подъемное устройство, удобная очистка, Эффект очистки более значитель, корпус горшка может выбрать сброс разрядов;

6. Корпус горшка принял три слоя импорта сварки пластины из нержавеющей стали, резервуары и трубопроводы для полировки зеркала, Полное соблюдение требований GMP;

7. В соответствии с технологическими требованиями, нагревание и охлаждающий материал резервуара, пара и электрический нагрев два метода нагрева в основном включают в себя;

8. Для обеспечения более стабильного управления машиной стабильно, Использование импортных электрических приборов, может полностью соответствовать международным стандартам;

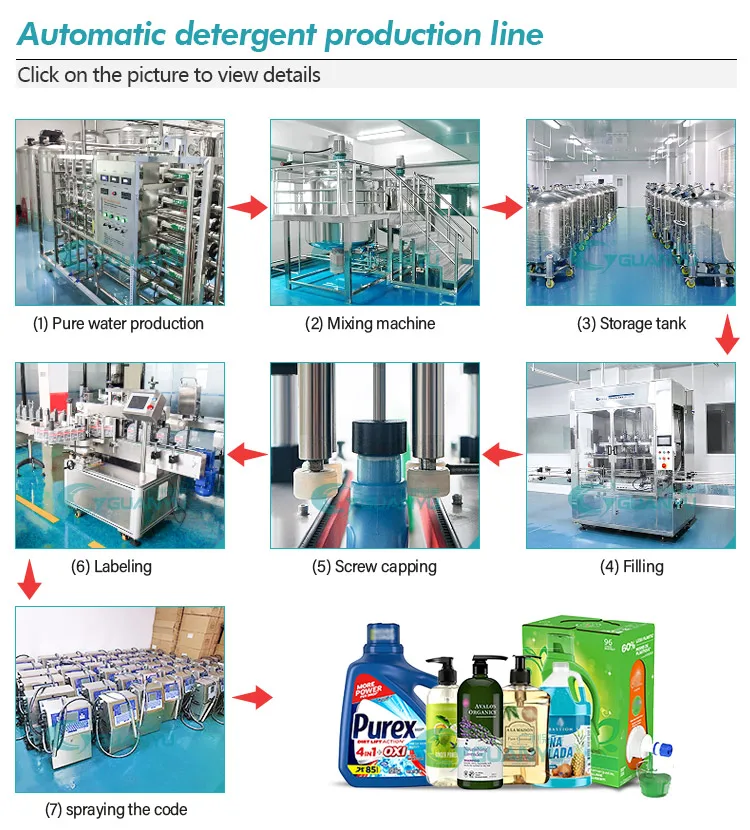

Конфигурация продукта

О нас

Успешный процесс рассмотрения дела

Сертификаты

Часто задаваемые вопросы

Отзывы

Пока нет отзывов.