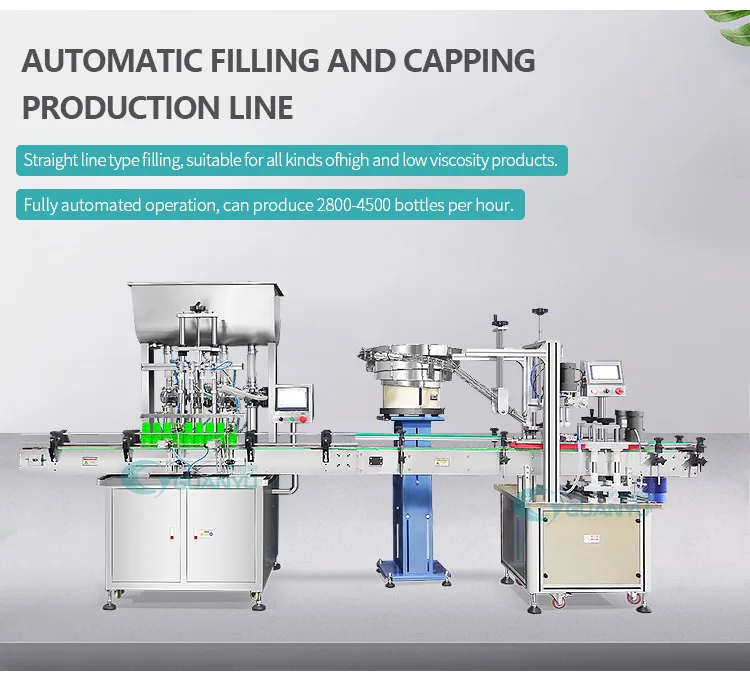

Максимальная скорость заполнения | Заполнение 200 мл, 2000~ 3000 ПК/час, Скорость будет отличаться, когда форма бутылки и размер шеи и наполненный материал, образующий и другое физическое свойство |

Применимый размер диаметра бутылки | 30-300(Мм) |

Применимый размер высоты бутылки | 30-350(Мм) |

Доза заполнения | 100~ 1000 мл (настраиваемое) |

Точность заполнения | ±1% |

Напряжение | AC220V, Одиночная фаза, 50/60Гц |

Власть | 1.0КВт |

Рабочее давление | 0.6МПа |

Программа управление | PLC+сенсорный экран интерфейс Man-Machine |

Скорость ограничения | 2000-3000 бутылки/час |

Нижний укрытие | Ручная или вибрирующая тарелка |

Машины направление | слева направо |

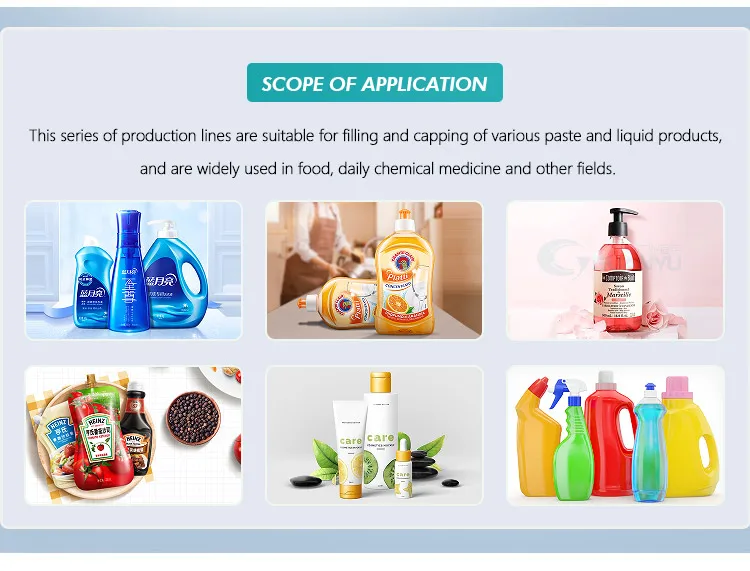

Основные функции (заполняющая машина):

1、Оборудование имеет сильную совместимость, и может быстро регулировать и заменить бутылки разных форм и спецификаций без замены деталей, который может соответствовать производственным требованиям множества сортов и спецификаций.

3、Использование международных компонентов бренда., производительность и стабильность、Пользователь может настроить диапазон заполнения, Материалов недостаточно в Хоппера, Компьютер даст сигнал питательного насоса Toaddmaterial по уровню датчика. Когда материал заполнен, насос будет останавливаться автоматически.5、Корпус машины сделан 304 нержавеющая сталь, Легко чистить, Машина полная соблюдение требований GMP.6、Перистальтическое насос или систему наполнения поршневого насоса, измерение точности, Удобные манипуляции.

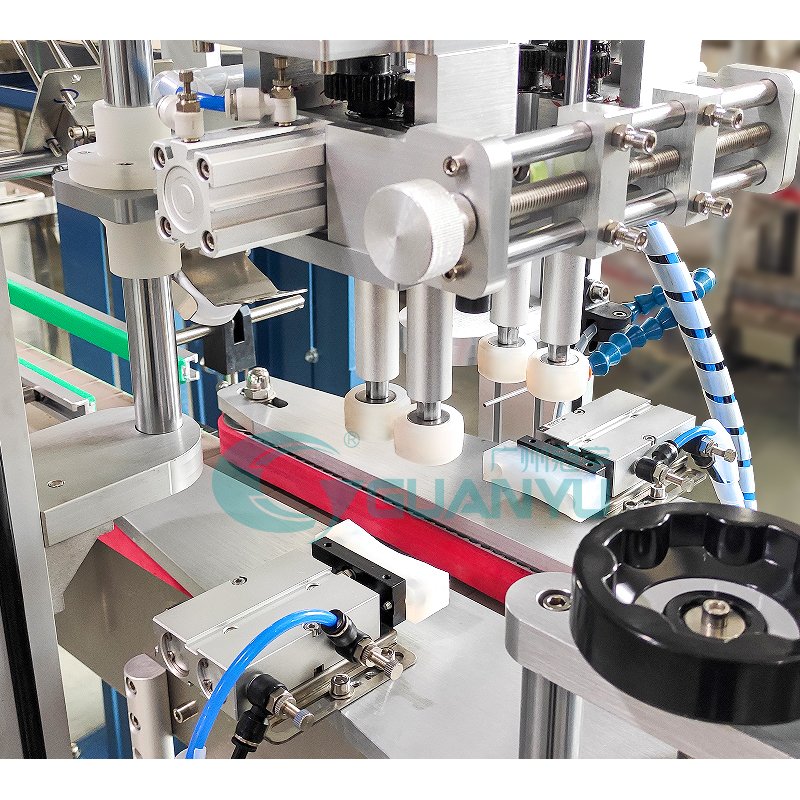

Основные функции (апппинг -машина):

2.Которые могут соответствовать упаковочной линии.3. Экран и работа кнопок может быть необязательными. 4. Что применяется для разных крышек в разных материалах и в разных спецификациях.5. Что применяет идентификационная кручение головы., Устройство перекрытия не может повредить крышку. ,это легко регулировать давление. ,винтовой крышка , Перетока, сжатие крышка, и т. д…

Отзывы

Пока нет отзывов.