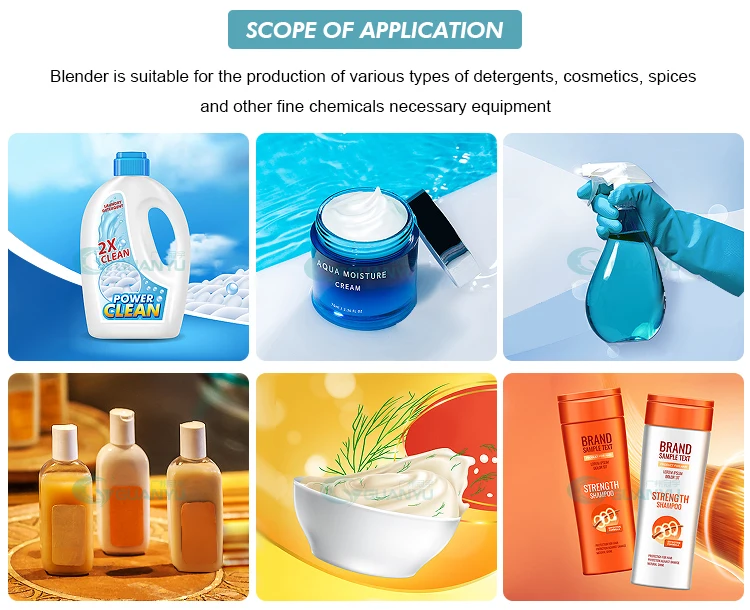

Индивидуальная 5000L жидкая мощная смесительная машина для производства моющих средств.

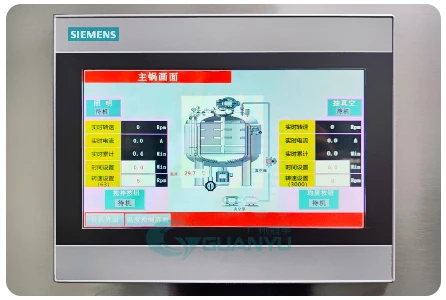

Функции:1. Материал контактной части SUS316L из нержавеющей стали SUS316L, Внутри и снаружи оборудования находятся с зеркальной полировкой и добраться до GMP.. Все трубопроводы и параметр контролируются автоматически. И электрическое устройство, которое импортируется из зарубежной страны,Как Сименс ,Schneider и т. Д. 3. Эмульгирующий бак с системой очистки CIP,Это делает уборку легкой и эффективной.4. Эзульгификация танка принимает третичную агитирующую систему, и во время эмульгирования ,Вся обработка находится в вакуумной среде, Таким образом, он может не только устранить Spume, созданный при обработке эмульгирования ,но также может избежать ненужного загрязнения.5. Гомогенизатор принимает самую передовую технологию,Он может получить идеальный эмульгирующий эффект. Скорость высокого эмульгирования составляет 0-3600R/мин., и скорость низкого смешивания составляет 0-63R/мин.

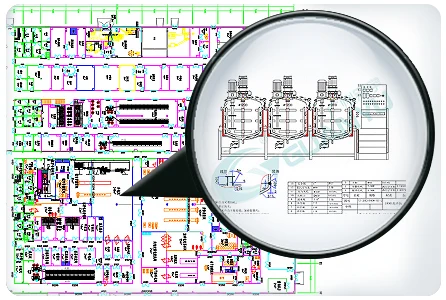

Модель | Объем(л) | Смешивание силы(кВт) | Скорость вращения смешивания(об/мин) | Гомогенизирующая сила(кВт) | Гомогенизирующая скорость вращения(об/мин) | Метод отопления |

Тренажерный зал | 200 | 1.5 | 0~ 63 | 4.0 | 0~ 3200 | Паровое отопление или электрическое отопление |

Тренажерный зал | 500 | 3.0 | 0~ 63 | 7.5 | 0~ 3200 | |

Тренажерный зал | 1000 | 4.0 | 0~ 63 | 11 | 0~ 3200 | |

Gym-1500 | 1500 | 5.5 | 0~ 63 | 11-15 | 0~ 3200 | |

Тренажерный зал-2000 | 2000 | 7.5 | 0~ 63 | 15-18.5 | 0~ 3200 | |

Тренажерный зал | 3000 | 7.5-11 | 0~ 63 | 18.5-22 | 0~ 3200 | |

Тренажерный зал | 5000 | 11-15 | 0~ 63 | 18.5-22 | 0~ 3200 |

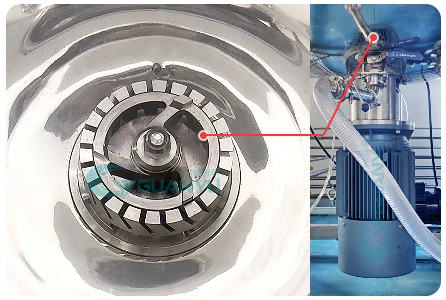

Смешивающая лопасть

Гомогенизатор

Регламент скорости преобразования частоты 0-3200R/мин, однородная режущая головка для высокоскоростной резки материалов, так, чтобы материалы полностью разбились и перемешались!

◭ Смешивание всестороннего скребки на стенах принимает частотный преобразователь для регулировки скорости , так что высококачественные продукты распределенных процессов в соответствии с требованиями клиента.

Вакуумные насосы

Пластин и рама теплообменника

Материал подъемник

Пневматический клапан

Консоль

Услуга

1..Кто мы?

Отзывы

Пока нет отзывов.