элемент | ценить |

Состояние | Новый |

Тип | Разливочная машина |

Пропускная способность машины | Другой, 2000Внедл, 3000Внедл |

Применимые отрасли | Еда & Фабрика напитков, Косметическая фабрика |

Расположение выставочного зала | Таиланд |

Приложение | Еда, Напиток, Химическая, Косметический |

Тип упаковки | Бутылки, Другой |

Упаковочный материал | Пластик, Стекло, Другой |

Автоматический класс | Автоматический |

Приводящий тип | Электрический |

Напряжение | 220V/380V |

Место происхождения | Китай |

Гуандун | |

Торговая марка | Гуанью |

Измерение(Д*Ш*В) | |

Масса | 1200КГ |

Гарантия | 1 Год |

Ключевые точки продажи | Высокая производительность |

Наполнительный материал | Пиво, Другой, Молоко, Вода, Масло, Сок, Жидкость, Вставить |

Точность заполнения | 99% |

Отчет о тестировании машин | Предоставил |

ВИДЕО ОТКРЫТИЕ-НЕПРАВИЧЕНИЕ | Предоставил |

Гарантия основных компонентов | 1 Год |

Основные компоненты | Сосуд давления, Насос, Другой, ПЛК |

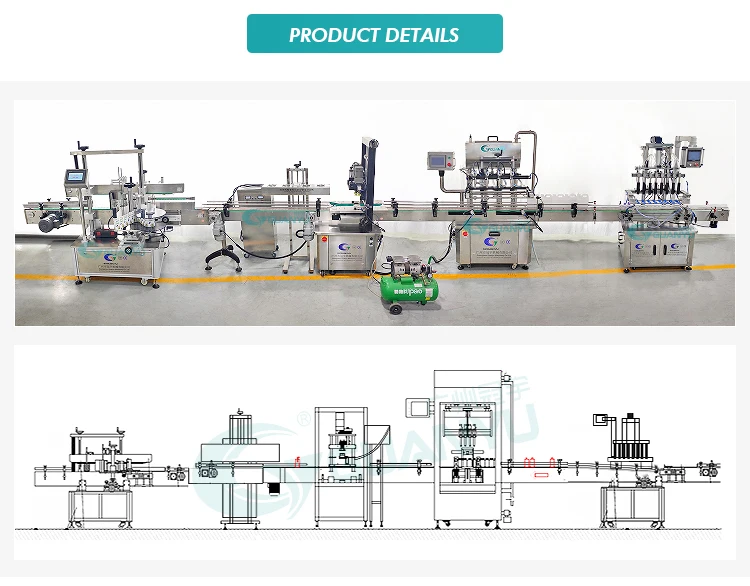

Название продукта | Filling Production Line |

Функция | Filling Capping Labeling |

Использование | Paste Cream Sauce Jam Lotion |

Ключевые слова | Automatic Filling Line |

Скорость заполнения | 1000-3000Внедл |

Материал | Нержавеющая сталь 304/316 |

Особенность | High Precision Filling Level |

Диапазон заполнения | 500-5000мл(Customisable) |

Контроль | PLC+ сенсорный экран |

Заполнение сопла | 2/4/6/8/10/12(индивидуально) |

Main Features(Negative ion dust removal machine):

1. Using precise double filtration, electrostatic ion generation ensures that no dust particles remain in the bottle.

2. Automatically store dust particles to ensure clean room air and operator health.

3. You can set the cleaning time according to your needs;

4. Use double (blow/inhale) mouthwash to remove dust from the bottle;

5. Use a precision filter (0.2один) to ensure the cleanliness of the air source;

6. It is suitable for assembly line operations, and can be matched with various assembly lines, with high efficiency

7. This machine can be used in beverage factories, food factories, chemical factories, cosmetics factories, pharmaceutical factories and other enterprises.

Основные функции (заполняющая машина):

1. Оборудование имеет сильную совместимость, и может быстро регулировать и заменить бутылки разных форм и спецификаций без замены деталей, который может соответствовать производственным требованиям множества сортов и спецификаций

2. ПЛК контроль ,операция с сенсорной бутылкой ,Простая и удобная работа.

3. Использование международных компонентов бренда., производительность и стабильность.

4. Пользователь может настроить диапазон заполнения, Материалов недостаточно в Хоппера, Компьютер даст сигнал питательного насоса

Addmaterial по уровню датчика. Когда материал заполнен, Насос будет останавливаться автоматически.

5. Корпус машины сделан 304 нержавеющая сталь, Легко чистить, Машина полная соблюдение требований GMP.

6. Перистальтическое насос или систему наполнения поршневого насоса, измерение точности, Удобные манипуляции.

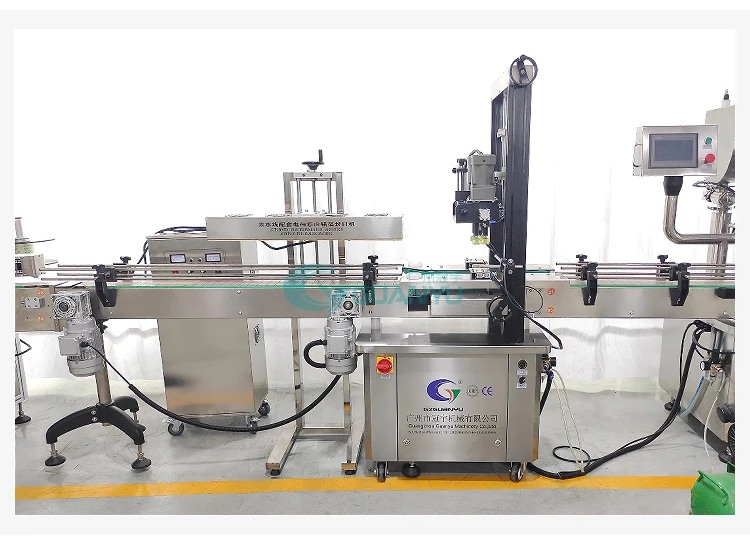

Основные функции (апппинг -машина):

1. Лифт крышки и вибрационный кормление могут быть выбраны в соответствии с формой крышки и типа крышки

2. Быстрая скорость задержки, регулируется из 0-45 бутылки/мин

3. Бутылки и крышки разных размеров могут поделиться машиной, настраивая или изменив несколько аксессуаров

4. Корпус резервуара оборудования не вращается, когда крышка ввинчивается, который избегает перемещения, рассеяние и возможное повреждение продуктов, содержащихся в резервуаре.

5. который применялся для разных крышек в разных материалах и в разных спецификациях.

6. который использует нож с 3-роллером. ,легко регулировать давление.

7. который применил для металлической крышки ,винтовой крышка , Перетока, сжатие крышка, и т. д…

Main Features(Labeling Machine):

1. Improve production efficiency, 20-60 части/мин

2. The whole machine is made of S304 stainless steel and high-grade aluminum alloy, which meets the production requirements of GMP

3. Controlled by PLC man-machine interface, data can be saved, and the data can be directly called when changing the bottle

4. This machine has the mechanism of bottle guiding, bottle dividing, маркировка, wheel leveling, counting and so on.

5. Wide range of application, labeling position, height and angle can be adjusted.

6. It can be connected to the conveyor belt to be used in the production line

Отзывы

Пока нет отзывов.