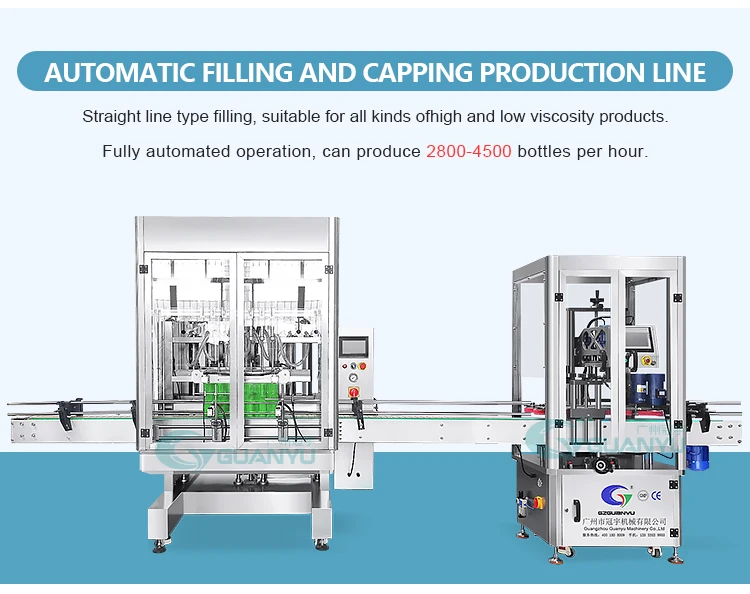

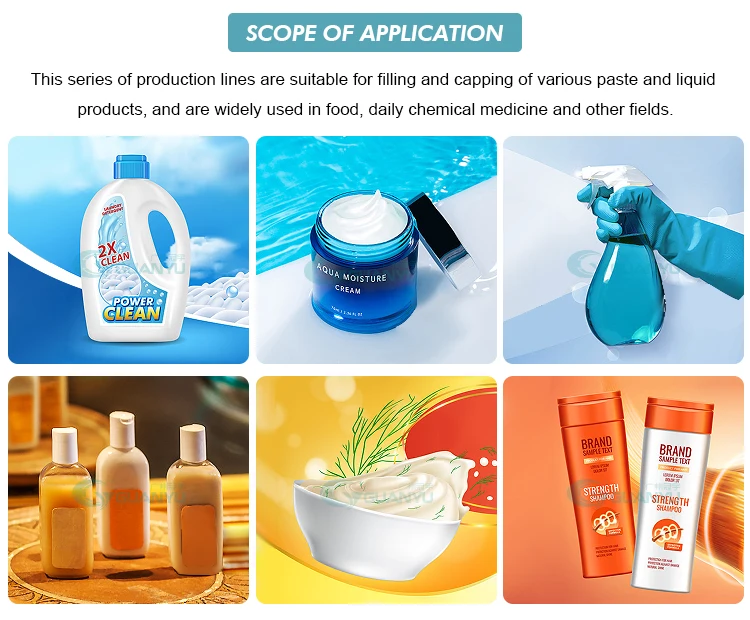

Автоматическая машина для розлива жидкого мыла в бутылки, линия для розлива и укупорки бутылочек для шампуня, крема и укупорки.

Описание продукции

Максимальная скорость заполнения: | Заполнение 200 мл, 2000~ 3000 ПК/час, Скорость будет отличаться, когда форма бутылки и размер шеи, а также образующий материал для наполнения и другие физические свойства |

Применимый размер диаметра бутылки: | 30-300(Мм) |

Применимый размер высоты бутылки: | 30-350(Мм) |

Доза заполнения: | 100~ 1000 мл (настраиваемое) |

Точность заполнения: | ±1% |

Напряжение: | 220V. / 380V (настраиваемый) |

Рабочее давление: | 0.6МПа |

Скорость ограничения: | 2000-3000 бутылки/час |

Нижний укрытие: | Ручная или вибрирующая тарелка |

Контроль сенсорного экрана

Панель управления сенсорным экраном делает его более удобным для настройки параметра. Он может заполнить жидкость, введя определенную диапазон заполнения,и визуальные рабочие данные помогают вам более точно заполнить жидкость.

Заполнение сопла

Наполнительная насадка с дизайном анти-плиты,Убедитесь, что производственная чистка 2/6/8 наполнение форсунки этой машины.

Световой датчик

Электрический глаз предназначен для обнаружения бутылок,предотвратить отсутствие или тратить бутылки. Он не заполнит жидкость, если бутылка не пройдет через,уменьшить производственную ошибку.

Автоматическое кормление

Заполняющая машина оснащена датчиком уровня жидкости. Когда материал в бункере ниже определенной позиции, Он будет автоматически подавать через систему кормления (Насос насоса/винтовой насос диафрагмы/ротор).

Контроль сенсорного экрана

Панель управления сенсорным экраном, Вы можете изменить время перекрытия, чтобы изменить стеснительность укрытия, с кнопкой аварийной остановки для обеспечения безопасности производства.

Заглушающая голова

Принять пластиковые колеса, нет вреда поверхности крышки при прикручивании крышки. Ширина может быть свободно отрегулирована, Uitable для множества различных форм/размеров бутылочных крышек

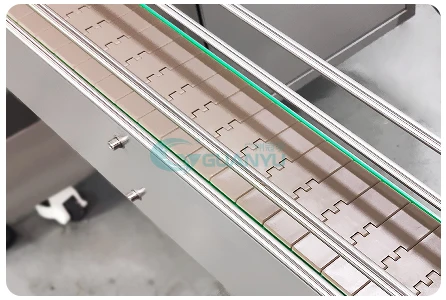

Конвейер

Эта машина оснащена автоматической конвейерной лентой, которое можно использовать с оборудованием для оборудования, такого как маркировочная машина для реализации автоматического производства и эффективного повышения эффективности работы.

Регулировка высоты

Регулируя ручку высоты, Рабочая высота может быть отрегулирована в соответствии с высотой бутылки. Это гарантирует, что машина может использоваться для столько же крышек бутылки, сколько

возможный.

возможный.

Отзывы

Пока нет отзывов.