Модель | Объем(л) | Смешивающая сила (KW) | Скорость вращения смешивания (R/M) | гомогенизирующая сила(кВт) | гомогенизирующая скорость(об/мин) | Метод отопления |

GY-200 | 200 | 1.5 | 0~ 63 | 4.0 | 0~ 3200 | Паровое отопление или отопление Electirc |

GY-500 | 500 | 3.0 | 0~ 63 | 7.5 | 0~ 3200 | |

GY-1000 | 1000 | 4.0 | 0~ 63 | 11 | 0~ 3200 | |

GY-1500 | 1500 | 5.5 | 0~ 63 | 11-15 | 0~ 3200 | |

GY-2000 | 2000 | 7.5 | 0~ 63 | 15-15.8 | 0~ 3200 | |

GY-3000 | 3000 | 7.5-11 | 0~ 63 | 18.5-22 | 0~ 3200 | |

GY-5000 | 5000 | 11 | 0~ 63 | 18.5-22 | 0~ 3200 |

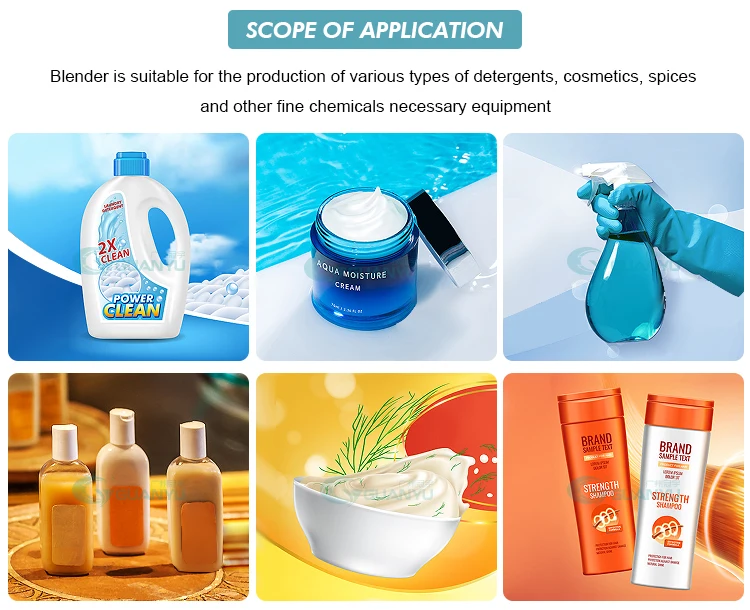

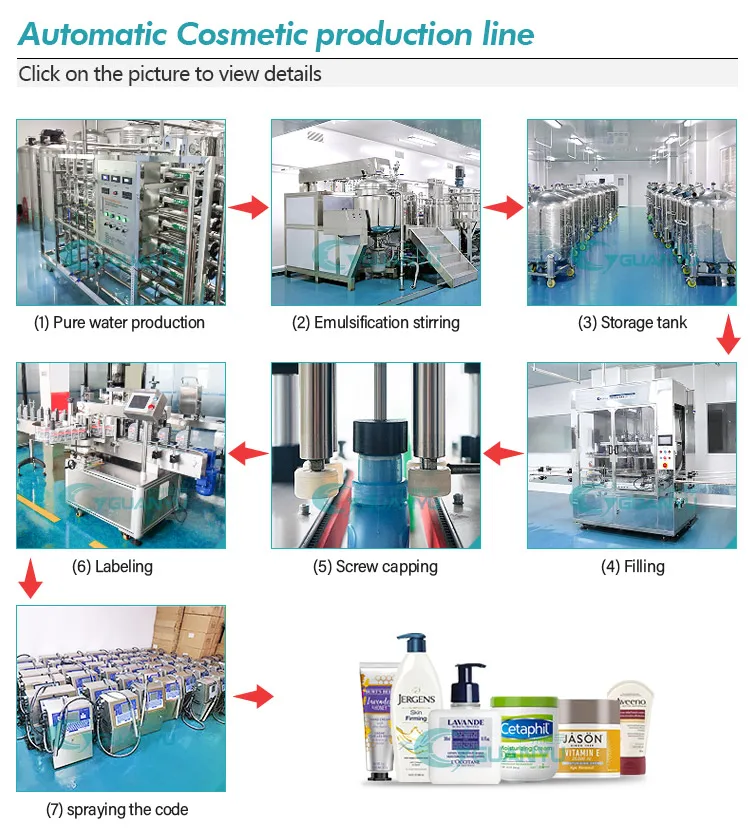

Выступления и функции

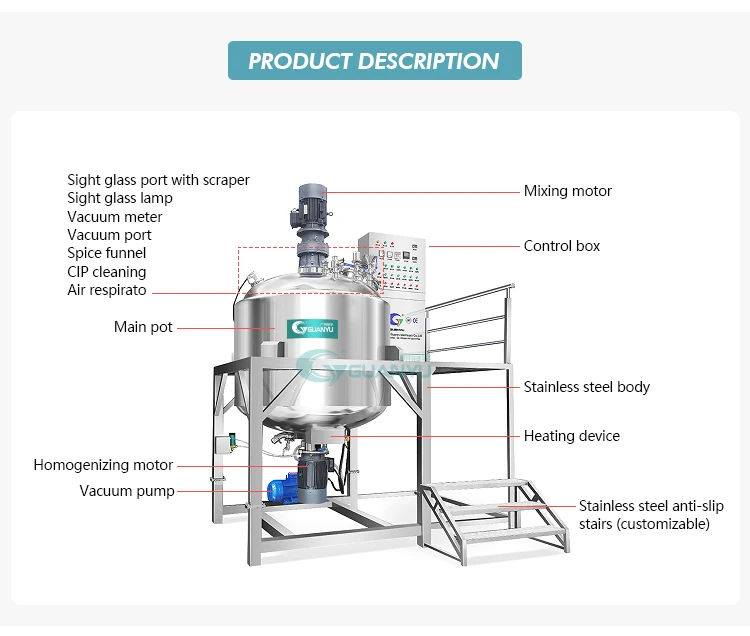

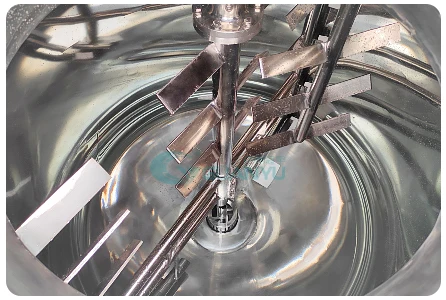

◭ Смешивание всестороннего скребки на стенах принимает частотный преобразователь для регулировки скорости , так высоко

качественные продукты различных процессов в соответствии с требованиями клиента.

◭ Диверсифицированный высокоскоростный гомогенизатор может мощно смешать твердое и жидкое сырье и может быстро растворить многие Indis

Растворимые материалы, такие как AES , Эза , LSA , и т. д.. Во время процесса производства жидких моющих средств, чтобы сэкономить энергосбережение

и сократить период производства.

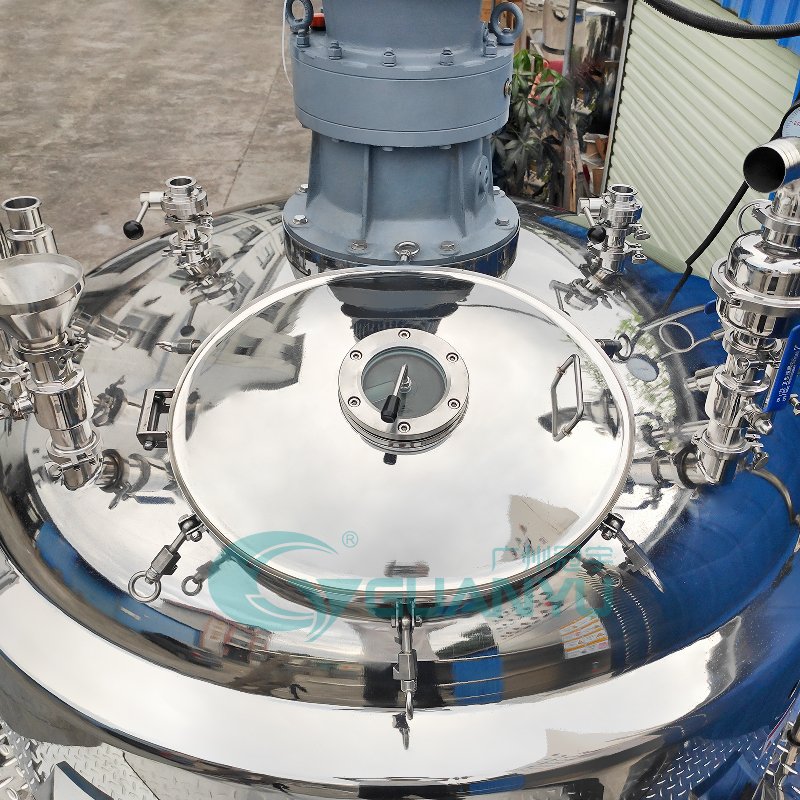

◭ Корпус горшка сварка импортной трехслойной пластиной из нержавеющей стали. Корпус резервуара и трубы принимают полировку рукавица , который

Полностью соответствует требованиям GMP.

◭cording по требованиям клиента , Танк может нагревать и прохладные материалы. Нагревание, включая нагревание парового и электричество

обогрев. Легко разряжать , нижний прямой разряд или переносным насосом.

Смешивающая лопасть

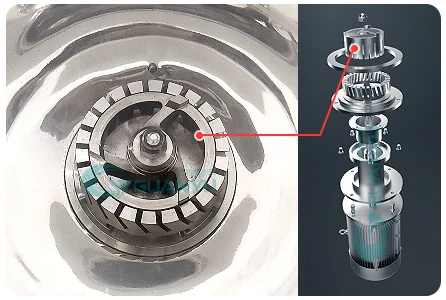

Гомогенизатор

Регламент скорости преобразования частоты 0-3200R/мин, однородная режущая головка для высокоскоростной резки материалов, так, чтобы материалы полностью разбились и перемешались!

Вакуумные насосы

Увольнять

(При необходимости, Выходной насос может быть оборудован для непосредственного извлечения материалов)

Консоль

Рабочая время, экстракция вакуума, Межслойное отопление, и т. д..

(Управление ПЛК необязательно)

Услуга

Используйте компоненты всемирно известных брендов, чтобы обеспечить качество оборудования и более длительный срок службы.

Отзывы

Пока нет отзывов.