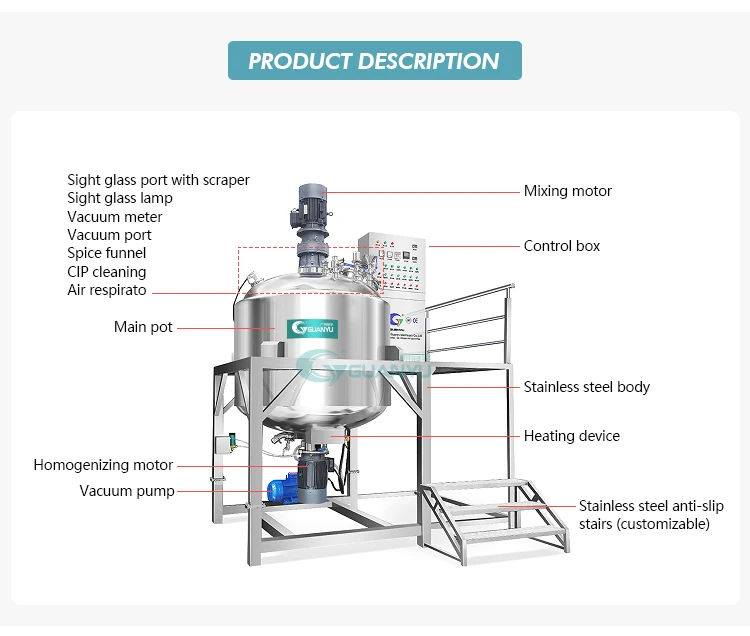

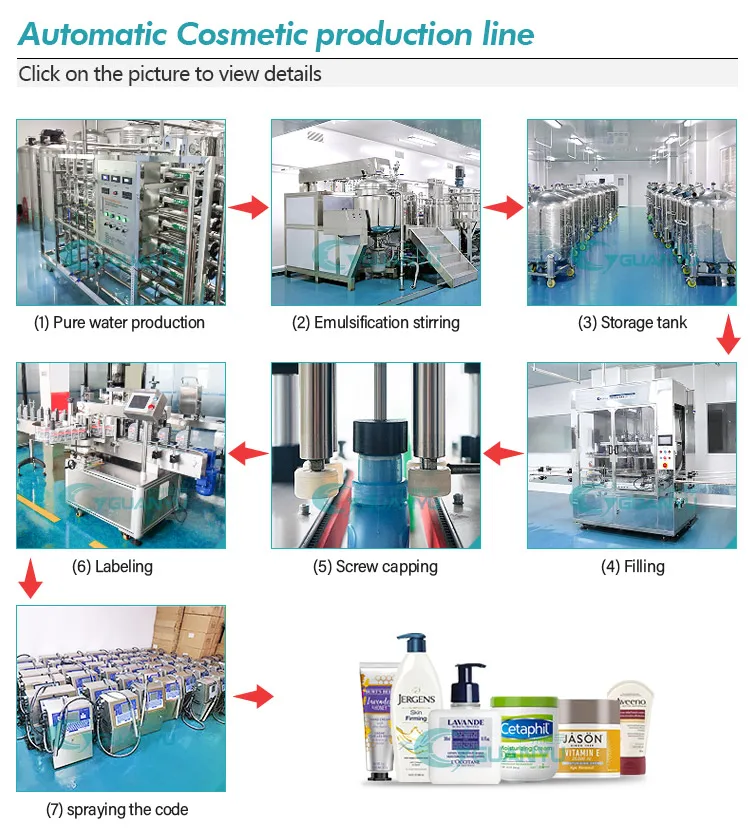

2000L Vacuum Homogenizing double jacket Stainless Steel High-speed Shearing Mixing Emulsifying Tank Machine cosmetic cream

Описание продукции

Модель | Объем(л) | Blending power(kw) | Blending rotation speed(r/m) | homogenizing power(кВт) | homogeniziing speed(об/мин) | heating method |

GY-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | steam heating or electirc heating |

GY-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GY-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GY-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GY-2000 | 2000 | 7.5 | 0~63 | 15-15.8 | 0~3200 | |

GY-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GY-5000 | 5000 | 11 | 0~63 | 18.5-22 | 0~3200 |

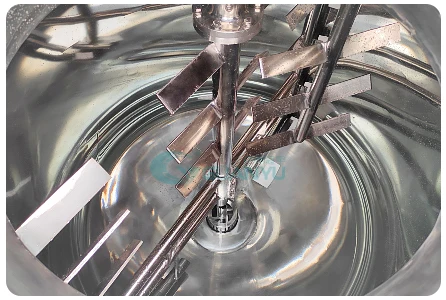

Смешивающая лопасть

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

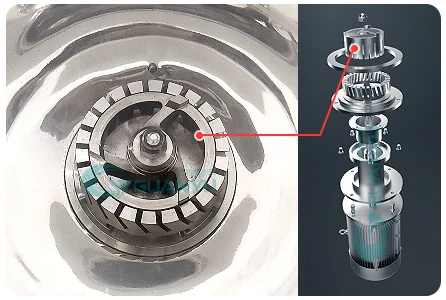

Гомогенизатор

Frequency conversion speed regulation 0-3200r/min, однородная режущая головка для высокоскоростной резки материалов, так, чтобы материалы полностью разбились и перемешались!

Vacuum Pumps

Under the vacuum environment, the emulsification pot can discharge foam when the materials are mixed, thus improving the quality of the materials to be treated. Vacuum deaeration process can ensure the sterility of materials

Discharge

The round bottom of the pot is designed to make the bottom discharge cleaner and reduce the residue of materials

(if necessary, a discharge pump can be equipped to directly extract materials)

(if necessary, a discharge pump can be equipped to directly extract materials)

Консоль

The control box includes settings such as homogeneous shearing, frequency conversion speed regulation mixing,

working timing, vacuum extraction, interlayer heating, и т. д..

(PLC control is optional)

working timing, vacuum extraction, interlayer heating, и т. д..

(PLC control is optional)

Услуга

Используйте компоненты всемирно известных брендов, чтобы обеспечить качество оборудования и более длительный срок службы.

Отзывы

Пока нет отзывов.