картонажная машина для коробок, вид автоматизированного упаковочного оборудования, предназначенный для оптимизации процесса упаковки различной продукции в картонные коробки.. Эти машины широко используются во многих отраслях промышленности., включая фармацевтические препараты, косметика, еда, и потребительские товары, обеспечение безопасной и эффективной упаковки продуктов, начиная от бутылок, трубки, и флаконы в пакетики, блистерные упаковки, и другие формы.

Машина для картонирования коробок автоматизирует весь процесс картонирования., включая складывание коробок, вставка продукта, добавление вставок, таких как листовки или руководства, и надежно запечатываем коробку. В этой статье рассматривается работа, функции, преимущества, и применение этих машин, а также информацию о различных типах, доступных на рынке.

Принцип работы коробки Картонирующие машины

Машины для картонирования коробок выполняют ряд автоматизированных этапов, которые включают загрузку продукта., формирование коробки, и герметизация. Ниже приведены основные этапы этого процесса.:

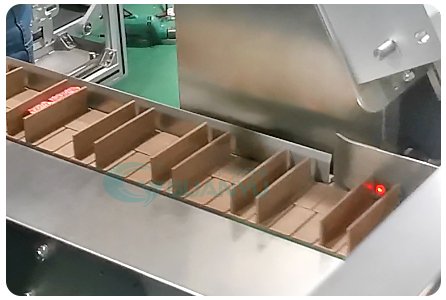

- Подача и открытие картонных коробок: Машина подает ровно, развернутые коробки из магазина или бункера в систему. Затем механическая рука или всасывающее устройство открывает коробки, придавая им желаемую форму.. Этот шаг гарантирует, что коробки правильно выровнены и готовы к заполнению..

- Вставка продукта: Продукт, что может быть бутылкой, трубка, или любой упакованный предмет, вставляется в открытую коробку. В зависимости от конфигурации машины, это можно сделать горизонтально или вертикально. В некоторых случаях, Дополнительный шаг может включать складывание брошюры или инструкции по эксплуатации и помещение ее в коробку вместе с продуктом..

- Запечатывание картона: После помещения продукта внутрь, машина запечатывает коробку, либо сложив и заправив клапаны, либо используя клей, например термоклей.. Некоторые машины предлагают варианты различных механизмов запечатывания в зависимости от конкретных требований к продукту или упаковке..

- Выгрузка картонной коробки: После того, как коробки заполнены и запечатаны, они автоматически выгружаются на конвейерную ленту или в систему вывода для дальнейшей обработки или упаковки..

Этот полностью автоматизированный процесс значительно сокращает ручной труд., минимизирует человеческую ошибку, и обеспечивает единообразие упаковки.

Основные характеристики коробки Картонирующие машины

Современная картонажная машина оснащена передовыми функциями, обеспечивающими высокую точность., адаптивность, и простота эксплуатации. Ниже приведены некоторые важные функции:

- Высокая автоматизация: Многие картонирующие машины сегодня имеют высокий уровень автоматизации., снижение необходимости ручного вмешательства. Они оснащены современным ПЛК. (Программируемый логический контроллер) системы, обеспечивающие бесперебойную работу и позволяющие настраивать различные параметры.

- Универсальность: Эти машины очень универсальны и могут обрабатывать широкий спектр типов продуктов и размеров коробок.. Будь то упаковка фармацевтических блистеров или косметических тюбиков., картонажная машина для коробок может адаптироваться к различным размерам и материалам.

- Скорость и эффективность: Высокоскоростные машины могут упаковывать несколько сотен коробок в минуту., в зависимости от размера и сложности изделия. Этот уровень эффективности необходим для крупномасштабных производственных сред..

- Системы обнаружения продуктов и картонных коробок: Многие машины оснащены датчиками и системами технического зрения, которые обеспечивают правильное размещение продукта и обнаруживают недостающие или смещенные элементы.. Это помогает предотвратить запечатывание и распространение дефектных коробок..

- Несколько вариантов уплотнения: Картонирующие машины часто предоставляют возможность запечатывания., например, защелкивающиеся застежки, клей уплотнители, или даже функции защиты от несанкционированного доступа, в зависимости от требований безопасности продукта.

- Удобный интерфейс: Большинство машин имеют интуитивно понятный человеко-машинный интерфейс. (HMI), что упрощает операторам контроль и настройку параметров по мере необходимости. Использование сенсорных экранов и подробных системных оповещений еще больше повышает удобство работы и эффективность..

- Прочная конструкция: Изготовлен из нержавеющей стали и других прочных материалов., эти машины спроектированы так, чтобы выдерживать суровые условия промышленного использования, сохраняя при этом гигиенические стандарты., особенно в фармацевтической и пищевой промышленности.

Типы картонационных машин

Существует два основных типа картонационных машин.: горизонтальный и вертикальный. Отличие заключается в том, как продукт вставляется в коробку..

- Горизонтальные картонажные машины: В этих машинах, продукты вставляются в коробку горизонтально. Горизонтальные картонирующие машины идеально подходят для таких продуктов, как тубы., флаконы, и бутылки, который легко помещается в коробку. Этот тип распространен в таких отраслях, как косметика и фармацевтика..

- Вертикальные картонажные машины: Вертикальные машины предназначены для вертикальной загрузки продукта в коробку.. Эти машины лучше подходят для таких продуктов, как пакеты., пакеты, или мешочки, который можно бросить в открытую коробку сверху. Вертикальные картонажные машины широко используются в пищевой промышленности и производстве напитков..

Некоторые продвинутые модели могут сочетать в себе как вертикальные, так и горизонтальные функции., предлагая большую гибкость для производителей, которым необходимо упаковывать разнообразную продукцию.

Применение картонационных машин

Машины для картонирования коробок нашли широкое применение в ряде отраслей промышленности., там, где эффективная и последовательная упаковка имеет решающее значение. Ниже приведены некоторые ключевые приложения:

- Фармацевтические препараты: В фармацевтической промышленности, необходимость в точной и гигиеничной упаковке имеет первостепенное значение. Картонажные машины для упаковки таблеток, капсулы, флаконы, и блистерные упаковки, часто с инструкцией внутри коробки. Машины обеспечивают соблюдение строгих нормативных стандартов упаковки..

- Косметика и уход за собой: Упаковка для косметики и средств личной гигиены, такие как кремы, лосьоны, и зубная паста, требует эстетической привлекательности и аккуратной упаковки. Картонирующие машины обеспечивают плавную и эффективную упаковку этих продуктов., поддержание визуальной идентичности бренда.

- Еда и напитки: Картонирующие машины используются для упаковки различных пищевых продуктов., от замороженных блюд и закусок до пакетиков чая и кофе. В этой отрасли, машины гарантируют, что упаковка защищена от несанкционированного вскрытия и загрязнения.

- Потребительские товары: Картонирующие машины также используются для упаковки потребительских товаров, таких как электроника., предметы домашнего обихода, и игрушки. Эти машины помогают защитить товары во время транспортировки и привлекательно представить их на полках магазинов..

Преимущества использования картонажной машины

Использование машин для картонирования коробок дает ряд преимуществ., включая:

- Повышенная производительность: Автоматизация приводит к ускорению производственных циклов, позволяя производителям производить больше единиц продукции в час, чем ручной труд когда-либо мог. Возможность непрерывной работы с минимальным вмешательством человека делает картонажные машины незаменимыми для производственных сред с высокими требованиями..

- Экономическая эффективность: Хотя картонирующие машины представляют собой первоначальные инвестиции, они могут привести к долгосрочной экономии за счет снижения затрат на рабочую силу, минимизация отходов упаковки, и улучшение пропускной способности.

- Согласованность и контроль качества: Автоматизированные машины обеспечивают стабильное качество упаковки., гарантируя, что каждая коробка заполнена, запечатанный, и маркированы в соответствии с точными спецификациями. Это исключает риск человеческой ошибки и повышает удовлетворенность клиентов..

- Снижение отходов материалов: Картонирующие машины предназначены для оптимизации использования упаковочных материалов., сокращение отходов. Точное складывание, склеивание, и процессы резки помогают производителям максимально эффективно использовать свои ресурсы.

- Повышенная безопасность: Для выполнения опасных или повторяющихся задач требуется меньше работников, картонирующие машины могут помочь снизить травматизм на рабочем месте и создать более безопасную среду для сотрудников..

Заключение

Машины для картонирования коробок произвели революцию в упаковочной промышленности, внедрив высокий уровень автоматизации., эффективность, и точность. Благодаря их способности обрабатывать широкий спектр продуктов и типов упаковки., они незаменимы в таких отраслях, как фармацевтика., косметика, еда, и потребительские товары. Инвестируя в высококачественную картонационную машину, предприятия могут значительно улучшить свои производственные процессы, обеспечить стабильное качество, и сократить эксплуатационные расходы, и все это при соблюдении современных требований к упаковке.

Машины для картонирования коробок играют жизненно важную роль в современных производственных линиях., обеспечение таких продуктов, как косметика, фармацевтика, и продукты питания эффективно упаковываются для распределения. В отраслях, требующих точного обращения, особенно при работе с чувствительными ингредиентами, такими как химикаты в пищевых добавках и витаминах, надежность упаковочных решений имеет важное значение. Правильно спроектированные картонирующие машины помогают сохранить целостность продукта во время упаковки.. Для получения дополнительной информации о высококачественных химических решениях, дополняющих эффективные производственные линии., вы можете посетить Синорайт широкий спектр предложений.

Привет! Signed up on 188jilicomlogin, and now I can say that the login process was smooth, so very nice. I wonder if they have some promotions for new customers? Only time will tell 188jilicomlogin

Been playing on neu88net for a while now. Pretty decent, honestly. Game selection is solid and I haven’t had any major issues withdrawing. Could be better, but it’s worth checking out. neu88net

Спасибо, что поделились. Я прочитал много ваших сообщений в блоге, прохладный, твой блог очень хорош.

Спасибо, что поделились. Я прочитал много ваших сообщений в блоге, прохладный, твой блог очень хорош. https://accounts.binance.com/en-ZA/register-person?ref=B4EPR6J0

Спасибо за то, что поделились. Я беспокоюсь, что мне не хватает творческих идей. Ваша статья вселяет во меня надежду. Спасибо. Но, У меня есть вопрос, Вы можете помочь мне?

Bet07, just signed up. Seems like a solid platform and good potential. Will check back here in a week to drop a real review. Might be worth checking out if you’re on the fence: bet07

I’ve been trying my luck at ganamaxcasino, and it’s pretty sweet. The site is easy to navigate, and they got a good variety of games. Стоит проверить, trust me. Access it here ganamaxcasino.

p9999gamedownload is a solid place for game downloads. Quick and easy, no crazy hoops to jump through. I like it. Get the newest version at p9999gamedownload.