Escolher a melhor máquina misturadora de cosméticos é muito importante. Ajuda a decidir como os cosméticos serão feitos no futuro. As empresas precisam fabricar produtos que sejam sempre iguais. Eles também querem trabalhar mais rápido. O mercado global de misturadores homogeneizadores pode atingir USD 2.66 bilhão por 2033. As principais máquinas misturadoras de cosméticos da atualidade possuem controles inteligentes e mais automação. Eles também são limpos e seguros de usar. Essas máquinas funcionam para grandes fábricas e pequenas lojas. Misturar com cuidado é muito importante na fabricação de cosméticos. Isso garante que cada lote seja de alta qualidade.

Takeaways -chave

Escolher a máquina misturadora de cosméticos certa torna os produtos melhores e mais rápidos de fabricar. Novos designs de mixer usam tecnologia inteligente para misturar mais rápido e manter cada lote igual. Alguns misturadores funcionam melhor para pós, cremes, ou líquidos, então escolha um que corresponda ao seu produto. Misturadores fáceis de limpar e automatizados economizam tempo e ajudam a manter os produtos sempre seguros e iguais. Comprar boas máquinas economiza dinheiro mais tarde, pois gera menos desperdício e produz produtos melhores.

Visão geral das principais máquinas misturadoras de cosméticos

Tabela de comparação

Escolher a direita máquina misturadora cosmética pode realmente mudar a forma como os cosméticos são feitos. As empresas analisam como as máquinas funcionam bem, quanta energia eles usam, e quão boa é a mixagem. A tabela abaixo mostra como diferentes misturadores cosméticos funcionam com fluidos espessos e finos. Esses resultados ajudam as empresas a escolher o melhor equipamento de fabricação de cosméticos para o que precisam.

Métrica de desempenho | Fluidos de Baixa Viscosidade | Fluidos de alta viscosidade |

|---|---|---|

Redução de potência do eixo | Aproximadamente 50% | |

Aprimoramento de mixagem (Índices de mistura) | Até 20% | Até 20% |

Dica: As empresas devem considerar esses números ao escolher máquinas misturadoras de cosméticos. Se a potência do eixo for menor, a máquina usa menos energia. Índices de mistura mais altos significam que o produto é mais uniforme.

2025 Inovações

Equipamentos para fabricação de cosméticos em 2025 tem novos recursos e designs mais inteligentes. Muitos misturadores cosméticos agora usam tecnologia avançada de micromisturadores. Essas novas ideias ajudam os mixers a trabalhar mais rápido e melhor, mesmo quando o fluxo é lento. Por exemplo, o micromixer TDSPM usa formas 3D e aprendizado de máquina para melhorar a mixagem. Micromisturadores de arranjo de pilares se misturam 99% com pouca pressão necessária. Alguns mixers usam defletores ou canais espirais para funcionar bem em muitas situações.

Projeto de micromisturador | Recurso -chave | Eficiência de mistura |

|---|---|---|

Micromisturador TDSPM | 3Projeto D, aprendizado de máquina | Superior |

Micromixer Pillar-Array | Novas matrizes de pilares | |

Micromisturador Confuso | Múltiplos defletores | ~93% |

Micromixer de canal espiral | Canal espiral logarítmico | Até 90% |

Essas novas ideias ajudam os equipamentos de fabricação de cosméticos a obter melhores resultados. As empresas agora podem escolher tipos de misturadores cosméticos adequados aos seus produtos. Projetos melhores também ajudam a tornar os produtos mais rápidos e a manter cada lote de alta qualidade.

Importância das máquinas de mistura de cosméticos

Qualidade do Produto

Equipamento de fabricação de cosméticos é muito importante para fazer bons produtos. As empresas usam máquinas misturadoras avançadas para garantir que os produtos sejam sempre iguais. Essas máquinas podem controlar a velocidade, temperatura, e tempo de mistura muito bem. Isso ajuda as empresas a seguir regras rígidas de qualidade.

Estudos da indústria mostram algumas coisas importantes:

O mercado de misturadores e liquidificadores diz que os cosméticos são uma grande parte de suas vendas.

Os misturadores planetários podem misturar muitos tipos de produtos. Isso ajuda as empresas a fabricar produtos especiais para os clientes.

Os misturadores para cosméticos são simples de limpar. Eles também atendem às regras de segurança alimentar e cGMP, para que os produtos permaneçam limpos e seguros.

A automação e a IoT ajudam as empresas a trabalhar melhor e a verificar a qualidade com mais facilidade.

Misturadores automáticos proporcionam controle exato, o que é muito importante para fazer cosméticos.

Indústria 4.0 a tecnologia ajuda os mixers a trabalhar de maneira mais inteligente. Isso significa que menos tempo é desperdiçado e os produtos são melhores.

Grandes empresas fabricam equipamentos de fabricação de cosméticos para indústrias com regras rígidas. Essas máquinas ajudam as empresas a manter alta qualidade e seguir todas as regras.

Misturando Desafios

Fazer cosméticos tem problemas especiais. Muitas receitas precisam de mistura cuidadosa porque os ingredientes têm texturas e espessuras diferentes. Alguns produtos, como cremes e loções, devem ser bem misturados para não se separarem. Os pós precisam ser misturados suavemente para não formarem grumos.

Os fabricantes também precisam pensar em:

Misturadores especiais que podem misturar lotes pequenos e grandes.

Máquinas fáceis de limpar, então os lotes não se misturam.

Equipamento que permite aos trabalhadores alternar rapidamente entre diferentes produtos.

O mercado de máquinas misturadoras, incluindo aqueles para cosméticos, está ficando maior. Isso significa que mais pessoas querem máquinas especiais que ajudem a fabricar bons produtos rapidamente. As empresas usam equipamento de fabricação de cosméticos para resolver esses problemas e fabricar produtos que os clientes desejam.

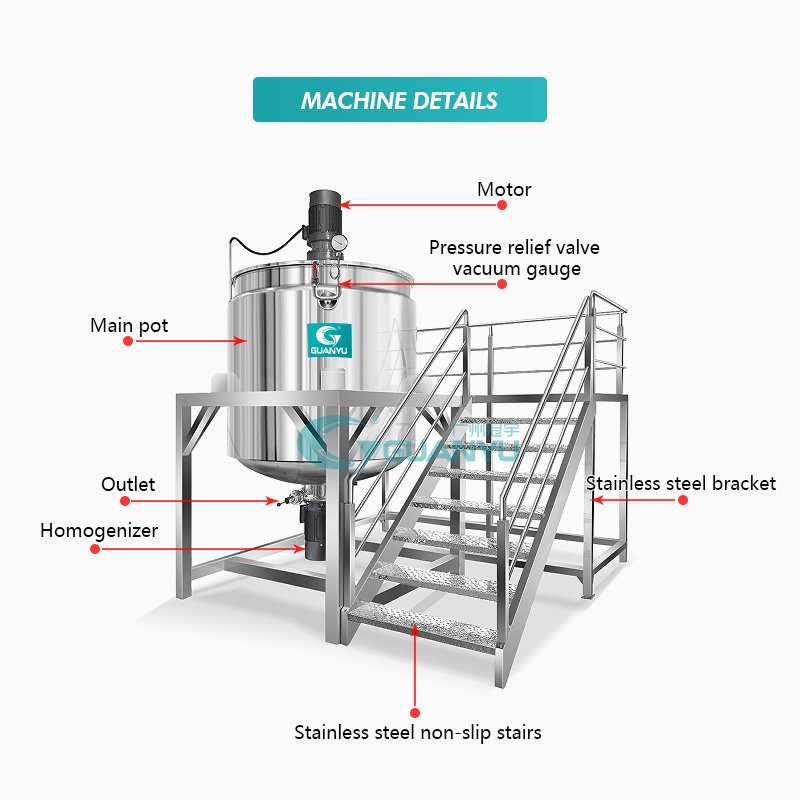

Misturador emulsionante a vácuo Guangzhou Guanyu

Características

Máquinas Co. de Guangzhou Guanyu., Ltda. é uma empresa bem conhecida em equipamentos cosméticos. O Misturador Emulsionante a Vácuo possui recursos especiais para mixagem cuidadosa e rápida. Ele usa mistura tripla, espumação a vácuo, e um sistema de homogeneização alemão. Você pode alterar a velocidade com um inversor de frequência de outro país. Isso ajuda a misturar muitos tipos de produtos. A batedeira pode usar aquecimento elétrico ou a vapor. Isso o torna bom para diferentes receitas. O tanque é brilhante e liso, que atende às regras GMP. Isso mantém os produtos seguros e limpos. O misturador pode levantar e inclinar, então a limpeza é simples. Guanyu também pode fazer com que o misturador se adapte às necessidades de cada cliente. Você pode escolher o tamanho do lote e o sistema de controle.

Especificações

Parâmetro | Detalhes |

|---|---|

CE, ISO9001:2000, Tuv | |

garantia | 1 ano (máquina & componentes principais) |

Faixa de volume | 15 eu- 1000 eu |

Poder | 4 quilowatts – 45 kW |

120V-480V | |

Velocidade do fuso | 1 – 6300 RPM |

Peso | 260 kg - 2500 kg |

Materiais | SUS304, SUS304L, SUS316, SUS316L |

Métodos de aquecimento | Elétrico ou a vapor |

Sistema de controle | Botão ou PLC |

Componentes do núcleo | Motor, engrenagem, vaso de pressão, caixa de velocidades, bombear, CLP, consequência, motor |

Limpeza | Polido espelhado, asséptico, Limpeza fácil |

Lugar de origem | Guangdong, China |

Aplicações

O Misturador Emulsificante a Vácuo é usado para muitos produtos cosméticos. Mistura cremes, loções, géis, pomadas, e soros. A mistura cuidadosa e o vácuo do misturador ajudam a fazer misturas suaves e estáveis. Também pode ser usado para medicina, comida, e produtos químicos diários. Isso o torna útil para muitos tipos de empresas.

Prós

Dá o mesmo, mistura de alta qualidade para cosméticos.

Pode ser feito para atender necessidades especiais de produção.

Construído com aço inoxidável forte para uso prolongado.

Possui certificações importantes como ISO9001, CE, e TUV.

Oferece bom suporte após a compra, com garantia de um ano e ajuda vitalícia.

Possui controles inteligentes e é fácil de limpar para um trabalho rápido.

Contras

Modelos maiores precisam de mais espaço nas fábricas.

O preço é mais alto do que os mixers simples devido aos recursos extras.

Misturador PerMix V

Características

O Misturador PerMix V é bom em misturar rápido. Possui uma câmara em forma de V que despeja pós e grânulos. Isso ajuda a misturá-los de forma rápida e uniforme. O misturador usa dispersão de Taylor e dinâmica de fluxo Dean. Isso ajuda a misturar os ingredientes, fazendo pequenas alterações na mistura. O design garante que tudo esteja bem distribuído. Você pode alterar a proporção e a taxa de fluxo. Isso significa que o misturador funciona para muitos tamanhos de lote e produtos.

A mistura pode chegar até 90% em menos de 100 milissegundos.

O mixer funciona bem em testes e em uso real.

O processamento automatizado de imagens verifica e controla a qualidade da mistura.

Especificações

Parâmetro | Detalhes |

|---|---|

Câmara de mistura | Em forma de V, aço inoxidável |

Faixa de capacidade | 2 eu- 5000 eu |

Eficiência de mistura | Até 90% |

Poder | 0.5 quilowatts – 15 kW |

Faixa de velocidade | 10 – 30 RPM |

Sistema de controle | Manual ou CLP |

Limpeza | Fácil acesso, superfícies lisas |

Recursos de segurança | Intertravamento, Proteção de sobrecarga |

Aplicações

O PerMix V Mixer é usado para misturar pós e grânulos. É popular no indústria cosmética. As empresas usam-no para pós faciais, máscaras secas, e outros produtos em pó. O misturador também é usado na medicina, comida, e produtos químicos. Sua mistura suave mantém o produto seguro e o mesmo tamanho de partícula.

Prós

Mistura pós e grânulos de forma rápida e uniforme.

O design pode ser alterado para diferentes tamanhos de lote.

Testes de laboratório mostram melhor compactabilidade e resistência em produtos mistos.

Você pode fazer o mixer funcionar melhor alterando o tempo e o tipo.

A limpeza é fácil porque a câmara é lisa.

Contras

A batedeira não mistura líquidos ou pastas tão bem quanto pós.

Misturadores maiores precisam de mais espaço na fábrica.

A mixagem funciona melhor se você carregar e usar da maneira certa.

Misturador Planetário Yuxiang

Características

O Misturador Planetário Yuxiang mistura as coisas muito bem. Ele usa dois lâminas de mistura que gira e se move pela tigela. Isso ajuda a misturar todas as partes do lote. Você pode alterar a rapidez com que ele se mistura. Isso é bom para diferentes tipos de produtos. O misturador tem um motor forte e uma caixa de velocidades. Ele também possui recursos de segurança como proteção contra sobrecarga e parada de emergência. O misturador é feito de aço inoxidável. Isso o mantém limpo e evita a ferrugem.

Especificações

Parâmetro | Detalhes |

|---|---|

Faixa de capacidade | 5 eu- 1000 eu |

Velocidade de mistura | 10 – 120 RPM |

Poder | 1.5 quilowatts – 30 kW |

Material | SUS304 / SUS316L |

Sistema de controle | CLP ou manual |

Opção de aquecimento | Tigela encamisada (opcional) |

Limpeza | Desmontagem fácil, Opção CIP |

Segurança | Sobrecarga, parada de emergência |

Aplicações

As pessoas usam o misturador planetário Yuxiang para muitas coisas. É ótimo para misturar cremes, géis, e pastas. Muitas empresas de cosméticos o utilizam em loções e máscaras. Também funciona para comida, medicamento, e produtos químicos. O misturador pode lidar com lotes pequenos e grandes. Isso o torna útil para muitos trabalhos.

Prós

Mistura coisas grossas e pegajosas uniformemente.

Funciona para lotes pequenos e grandes.

A limpeza e a fixação são simples.

Tem boa segurança para os trabalhadores.

Permite alterar a velocidade para diferentes receitas.

Contras

O mixer é pesado e difícil de mover.

Custa mais do que simples misturadores.

Você precisa de trabalhadores treinados para usá-lo bem.

Misturador de entrada superior Raiden

Características

O Raiden Top Entry Mixer é construído para durar e funciona bem. Tem um 3 motor elétrico à prova de explosão de potência. Este motor dá ao mixer muita potência para trabalhos difíceis. Você pode alterar a velocidade para se adequar a diferentes produtos. O gabinete IP55 mantém respingos de água e poeira longe do motor. Isso torna o misturador seguro em muitas fábricas. O design de entrada superior mistura de cima usando uma hélice ou impulsor. Esta configuração é boa para tanques grandes e contêineres profundos. O misturador pode misturar fluidos espessos e finos. Isso o torna útil para muitos produtos cosméticos.

Especificações

Parâmetro | Detalhes |

|---|---|

Energia motora | 3 HP (À prova de explosão) |

Controle de velocidade | Variável |

Classificação do gabinete | IP55 (Resistente à água e poeira) |

Capacidade de mistura | Até 134 pés cúbicos |

Tipo de montagem | Montagem de placa (entrada superior) |

Elemento de mistura | Hélice/Impulsor |

Faixa de aplicação | Fluidos de baixa a alta viscosidade |

Aplicações

Muitas indústrias usam o misturador Raiden Top Entry. É comum em cosméticos misturar cremes, loções, e géis. O misturador também funciona em produtos químicos, comida, e fábricas de medicamentos. Seu motor forte e controle de velocidade ajudam a misturar coisas grossas e finas. O design de entrada superior é fácil de configurar em tanques grandes. As pessoas escolhem este mixer quando precisam sempre dos mesmos resultados.

Prós

Motor à prova de explosão mantém os trabalhadores seguros em locais de risco.

Você pode alterar a velocidade para diferentes trabalhos de mixagem.

O gabinete IP55 impede a entrada de poeira e água.

Pode misturar grandes lotes e muitos tipos de fluidos.

Simples de colocar em tanques já em uso.

Observação: O Raiden Top Entry Mixer é forte e seguro. É uma boa escolha para muitas fábricas.

Contras

O mixer é pesado e pode precisar de montagens especiais.

Pode não funcionar bem para lotes muito pequenos.

Não há testes públicos para mostrar quão bem funciona.

Misturador Rotor-Estator Silverson

Características

O Silverson Rotor-Stator Mixer é um misturador forte de alto cisalhamento. Ele usa um sistema rotor-estator para misturar as coisas muito bem. Este sistema faz zonas de mistura fortes. Ele quebra partículas e gotículas rapidamente. O misturador funciona com muitas viscosidades, então cabe em muitos trabalhos cosméticos. Você pode escolher diferentes cabeçotes rotor-estator para suas necessidades. Limpar o misturador é simples e você pode trocar os lotes rapidamente. Silverson possui misturadores para laboratórios e grandes fábricas. Isso significa que os resultados permanecem os mesmos quando você ganha mais. Os mixers possuem recursos de segurança e controles fáceis.

Especificações

Parâmetro | Detalhes |

|---|---|

Faixa de potência | 0.37 quilowatts – 75 kW |

Capacidade | 1 eu- 12,000 eu |

Velocidade do Rotor | Até 10,000 RPM |

Material | Aço inoxidável (grau alimentício e farmacêutico) |

Cabeças de mistura | Intercambiável (em geral, emulsor, desintegrando, ranhurado) |

Limpeza | CIP (Limpeza no local) e fácil desmontagem |

Opções de controle | Manual, digital, ou CLP |

Segurança | Proteção contra sobrecarga, parada de emergência |

Aplicações

Misturadores de alto cisalhamento Silverson são importantes na fabricação de cosméticos. Eles misturam cremes, loções, géis, e soros. O misturador espalha pós e mistura óleos com água. Isso torna os produtos suaves e estáveis. Muitas indústrias usam esses misturadores, como comida, medicamento, e produtos químicos. Em cosméticos, o misturador ajuda a fazer pequenas partículas e até texturas. Também ajuda a misturar produtos espessos e partículas minúsculas.

Prós

Mistura muitos produtos de forma rápida e uniforme.

A limpeza é fácil e você pode alterar os lotes rapidamente.

Funciona bem do laboratório à grande fábrica.

Bom suporte e testes no local ajudar os usuários.

Silverson permite que os clientes testem os mixers antes de comprar. Isso os ajuda a ver como o mixer funciona.

Contras

O misturador custa mais do que simples misturadores.

Altas velocidades podem usar mais energia às vezes.

Alguns empregos precisam que os trabalhadores aprendam como usá-los melhor.

Misturador de pó seco V Blender

Características

O Misturador de pó seco V Blender mistura pós suavemente, mas bem. Possui uma câmara em forma de V que gira e faz os pós caírem. Isso ajuda a misturá-los sem usar força forte. A mistura suave mantém seguros os materiais frágeis ou sensíveis ao calor. Você pode alterar a quantidade de pó colocada e a velocidade com que ela gira. Isso permite misturar lotes pequenos ou grandes. A batedeira possui travas de segurança e portas fáceis de abrir para limpeza. Muitos misturadores possuem revestimentos antiestáticos. Isso evita que o pó grude e facilita a limpeza. O V Blender pode ser usado com controles manuais ou automáticos. Isso significa que funciona em muitos tipos de fábricas.

A câmara em forma de V tomba bem os pós

A velocidade e o nível de preenchimento podem ser alterados

O revestimento antiestático ajuda na limpeza

Fechaduras de segurança e portas fáceis de abrir

Especificações

Parâmetro | Detalhes |

|---|---|

Faixa de capacidade | 5 eu- 5000 eu |

Velocidade rotacional | 10 – 45 RPM |

Material | Aço inoxidável ou acrílico |

Nível de preenchimento | 35% – 65% |

Limpeza | Fácil acesso, revestimento antiestático |

Sistema de controle | Manual ou CLP |

Segurança | Intertravamentos, Proteção de sobrecarga |

Aplicações

As pessoas usam o misturador de pó seco V Blender para misturar pós secos e grânulos. É frequentemente usado em cosméticos para pós faciais e blushes.. A mistura suave mantém o tamanho e a textura do pó iguais. Isto é importante para bons produtos cosméticos. Medicamento, comida, e empresas químicas também usam este misturador. Isso os ajuda a obter combinações uniformes.

Prós

Mistura pós secos e grânulos uniformemente

A mistura suave mantém os ingredientes seguros

Limpeza e cuidado são simples

Funciona para lotes pequenos ou grandes

Pode ser alterado para diferentes trabalhos

Os testes mostram que o V Blender mixa melhor que outros mixers. Isso é verdade quando você carrega de ambos os lados. Os cientistas usaram testes de laboratório e modelos de computador para verificar isso. Eles observaram como estava a mistura com fotos e Curvas RSD. O V Blender se saiu melhor nesses testes.

Contras

Não funciona com líquidos ou pastas pegajosas

Lotes grandes podem demorar mais para serem misturados

Você deve carregá-lo com cuidado para obter melhores resultados

Estudos em medicina mostram tempo de mistura ajuda a controlar quão uniforme é a mixagem. Os cientistas descobriram que nível de enchimento e velocidade mudar o quão bem ele se mistura. Verificar amostras e usar dados ajuda a manter os mesmos resultados.

Misturador Cosmético Industrial

Características

Misturadores cosméticos industriais usar novas tecnologias para misturar as coisas de forma rápida e uniforme. Muitos têm mistura centrífuga planetária, que faz forças fortes. Essas forças ajudam a quebrar as partículas e tornar o produto suave. Os misturadores são feitos com peças de aço inoxidável. Isso os torna fáceis de limpar e duram muito tempo. Alguns mixers permitem definir a velocidade e o tempo para cada lote. Você pode fazer isso com controles especiais. Recursos de segurança como intertravamentos e proteção contra sobrecarga mantêm os trabalhadores seguros.

Especificações

Parâmetro | Detalhes |

|---|---|

Faixa de capacidade | 10 eu- 2000 eu |

Tecnologia de mistura | Centrífuga planetária, alto cisalhamento |

Material | Aço inoxidável (grau alimentício e farmacêutico) |

Faixa de velocidade | 10 – 3000 RPM |

Sistema de controle | Manual, digital, ou CLP |

Limpeza | CIP (Limpeza no local), desmontagem fácil |

Segurança | Intertravamentos, Proteção de sobrecarga |

Aplicações

Misturadores cosméticos industriais são usados em muitos lugares. As empresas os utilizam para fazer cremes, loções, e emulsões. Eles também ajudam a fazer géis e soros com texturas suaves. As fábricas usam esses misturadores para lotes pequenos e grandes. Outras indústrias como medicina, comida, e os produtos químicos também os usam. Os misturadores ajudam a tornar os produtos sempre iguais e economizam tempo.

Prós

Torna as misturas uniformes e estáveis para bons produtos.

Funciona para lotes pequenos e grandes.

Fácil de limpar e cuidar, então menos espera.

O aço inoxidável mantém as coisas limpas e fortes.

Controles especiais ajudam a tornar o processo exato e repetível.

Misturadores funcionam bem em cosméticos, medicamento, e comida.

Os fabricantes dizem que esses misturadores ajudam a tornar os cuidados com a pele suaves e duradouros. Estudos mostram melhor qualidade do produto e mais controle sobre o processo.

Contras

Custa mais no início do que misturadores simples.

Alguns misturadores precisam de trabalhadores treinados para usá-los bem.

Grandes misturadores precisam de mais espaço na fábrica.

Misturador homogeneizador de bancada

Características

Misturadores homogeneizadores de bancada misturam bem, mas são pequenos. Eles têm um motor forte e um sistema rotor-estator rápido. Você pode alterar a velocidade para diferentes produtos. Esses misturadores cabem em bancadas de laboratório ou mesas pequenas. Muitos têm controles digitais para Mistura. Recursos de segurança como proteção contra sobrecarga e desligamento automático mantêm pessoas e máquinas seguras. Você pode desmontá-los rapidamente, então a limpeza é fácil.

Dica: Os misturadores homogeneizadores de bancada são ótimos para equipes que testam rapidamente novas fórmulas cosméticas.

Especificações

Parâmetro | Detalhes |

|---|---|

Faixa de capacidade | 0.2 eu- 10 eu |

Poder | 0.2 quilowatts – 2 kW |

Faixa de velocidade | 3,000 – 30,000 RPM |

Material | Aço inoxidável (peças de contato) |

Sistema de controle | Digitais ou manuais |

Limpeza | Desmontagem sem ferramentas |

Segurança | Sobrecarga, desligamento automático |

Aplicações

Laboratórios e pequenos produtores usam misturadores homogeneizadores de bancada para muitos trabalhos. Eles misturam cremes, loções, e soros para cosméticos. Esses misturadores também ajudam com amostras em testes de medicamentos e alimentos. O equipamento faz bem, emulsões e dispersões estáveis. Os pesquisadores usam esses misturadores para fazer novos produtos e melhorar os antigos.

Prós

O tamanho pequeno economiza espaço em laboratórios e áreas de trabalho.

A alta velocidade torna as misturas suaves e uniformes.

Limpeza e cuidado são simples.

Você pode alterar a velocidade de muitos produtos.

A configuração rápida ajuda as equipes a trabalhar mais rapidamente.

Contras

Só é possível misturar pequenos lotes de uma só vez.

Não é bom para materiais muito grossos.

Pode ser necessário misturar muitos lotes pequenos para grandes necessidades.

Misturador homogeneizador portátil

Características

Misturadores homogeneizadores manuais são fáceis de usar e movimentar. Eles são bons para pequenos trabalhos e trabalhos de laboratório. Esses misturadores possuem um sistema rotor-estator de alta velocidade. Este sistema quebra as partículas e mistura as coisas rapidamente. Você pode colocar o mixer em recipientes diferentes. Isso ajuda a economizar tempo ao trocar lotes. Muitos misturadores permitem alterar a velocidade de cada produto. São leves e possuem alças que cabem na sua mão. Isso os torna simples de usar por um longo tempo. Alguns misturadores possuem recursos de segurança como proteção contra sobrecarga e protetores contra respingos.

Dica: Os misturadores homogeneizadores portáteis são ótimos para testes rápidos e pequenos lotes em laboratórios de cosméticos.

Especificações

Parâmetro | Detalhes |

|---|---|

Faixa de capacidade | 50 mL – 5 eu |

Poder | 100 – 800 C |

Faixa de velocidade | 5,000 – 35,000 RPM |

Material | Eixo/lâmina de aço inoxidável |

Sistema de controle | Manual ou digital |

Peso | 1 – 3 kg |

Limpeza | Eixo destacável, enxágue fácil |

Segurança | Proteção contra sobrecarga, protetor contra respingos |

Aplicações

Os misturadores homogeneizadores portáteis ajudam de muitas maneiras na cosmética. Eles misturam cremes, loções, soros, e géis em pequenas quantidades. As equipes os utilizam para testar novas fórmulas antes de criar lotes maiores. Os laboratórios usam esses misturadores para preparar amostras e verificar se os produtos são iguais. Eles também são usados para ensino e treinamento em ciências cosméticas..

Prós

Fácil de transportar e usar

Rápido de configurar e limpar

Bom para misturar pequenos lotes e amostras

A velocidade pode ser alterada para cada produto

Economiza dinheiro para laboratórios e novas empresas

Contras

Funciona apenas para lotes pequenos

Não é bom para lotes grossos ou grandes

Usar à mão pode deixá-lo cansado se usado por muito tempo

Misturador de montagem superior

Características

Misturadores de montagem superior são fortes e trabalham em muitos lugares. Eles ficam em cima de tanques ou embarcações. Um motor gira um eixo com impulsores para misturar de cima. Você pode alterar a velocidade para se adequar a diferentes produtos. Isso ajuda os trabalhadores a escolher a rapidez com que misturam. O mixer é simples de colocar e tirar. Alguns mixers mostram velocidade e torque em uma tela. Peças de segurança como proteção contra sobrecarga e botões de parada mantêm as pessoas seguras.

Dica: Os misturadores de montagem superior são bons para linhas de produção novas ou antigas.

Especificações

Parâmetro | Detalhes |

|---|---|

Tipo de montagem | Entrada principal (flange ou braçadeira) |

Faixa de potência | 0.5 quilowatts – 22 kW |

Comprimento do eixo | 500 milímetros – 3000 mm |

Tipos de impulsor | Hélice, turbina, ou âncora |

Faixa de velocidade | 50 – 1800 RPM |

Material | Aço inoxidável (304/316eu) |

Sistema de controle | Manual ou CLP |

Segurança | Sobrecarga, parada de emergência |

Aplicações

Misturadores de montagem superior são usados em muitos trabalhos. Eles misturam líquidos, Rodas, e semissólidos. Em cosméticos, eles misturam cremes, géis, e loções. Outras empresas os utilizam para alimentação, produtos químicos, e medicina. Esses misturadores funcionam em tanques pequenos ou grandes. Isso os torna bons para muitos tipos de produção.

Prós

Simples de configurar e corrigir

Adapta-se a muitos tamanhos e formatos de tanques

Mistura materiais grossos e finos

Permite alterar a velocidade para melhor controle

Feito de aço inoxidável forte

Contras

Os tanques podem precisar de alterações para adicionar o misturador

Não é o melhor para materiais muito grossos

O eixo pode ser muito curto para tanques profundos

Comparação de máquinas misturadoras de cosméticos

Desempenho

O desempenho é muito importante na hora de escolher equipamento de fabricação de cosméticos. Misturadores de alto cisalhamento misturam cremes, loções, e géis de forma rápida e uniforme. Muitas fábricas escolhem essas máquinas porque trabalham com produtos grossos e finos. A melhor máquina misturadora de cosméticos mistura mais rápido e mantém os produtos sempre iguais. Alguns misturadores de cosméticos possuem controles inteligentes para garantir que cada lote corresponda. As equipes de controle de qualidade usam essas máquinas para atender regras rígidas nas fábricas.

Tipo de misturador | Faixa de tamanho de lote | Velocidade de mistura | Melhor para |

|---|---|---|---|

Mixers de cisalhamento alto | Pequeno a grande | Rápido | Cremes, emulsões |

Misturadores Planetários | Médio a Grande | Moderado | Géis, pastas |

Misturadores V | Pequeno a grande | Gentil | Pós, misturas secas |

Dica: Misturadores de alto cisalhamento são melhores para produtos suaves e estáveis.

Características

Equipamentos de fabricação de cosméticos têm muitos recursos úteis agora. Algumas máquinas possuem telas sensíveis ao toque e configurações que você pode programar. Outros são fáceis de limpar e possuem desligamentos de segurança. Muitas máquinas de mistura de cosméticos permitem alterar a velocidade e a temperatura. Você também pode escolher opções que atendam às suas necessidades. Esses recursos ajudam as empresas a economizar tempo e cometer menos erros.

Os controles programáveis ajudam a obter sempre os mesmos resultados

Superfícies fáceis de limpar agilizam a troca de produtos

Os intertravamentos de segurança mantêm os trabalhadores seguros

A flexibilidade do tamanho do lote permite produzir mais ou menos produto

Preço

O preço muda dependendo do tipo de máquina misturadora cosmética e suas características. Os misturadores básicos de alto cisalhamento custam menos, mas têm menos opções. Grandes máquinas com mais automação custam mais dinheiro. As empresas devem pensar no valor total, como suporte e garantia. Comprar boas máquinas pode economizar dinheiro mais tarde, evitando quebras e fabricando produtos melhores.

Tipo de misturador | Faixa de preço (USD) |

|---|---|

Misturadores de bancada | $2,000 – $10,000 |

Misturadores industriais | $15,000 – $80,000 |

Sistemas Automatizados | $50,000 – $200,000+ |

Observação: Gastar dinheiro em bons equipamentos de fabricação de cosméticos ajuda a fabricar produtos melhores e um trabalho mais rápido.

Escolhendo máquinas de mistura de cosméticos

Tamanho do lote

Os fabricantes precisam escolha misturadores que se encaixem o tamanho do lote. Laboratórios pequenos usam misturadores de bancada ou portáteis para lotes pequenos. Grandes fábricas precisam de máquinas industriais para grandes quantidades. Escolher o misturador certo para o tamanho do lote evita o desperdício. Também ajuda a produção a funcionar sem problemas.

Dica: Sempre verifique o menor e o maior tamanho de lote que uma máquina pode suportar antes de comprá-la.

Complexidade da Fórmula

Alguns produtos cosméticos são fáceis de fazer. Outros precisam de mistura especial. Receitas difíceis com pós, Óleos, e ativos precisam misturadores de alto cisalhamento ou planetários. Esses misturadores misturam tudo uniformemente. Receitas fáceis podem usar misturadores básicos. Os fabricantes devem analisar suas receitas antes de escolher uma máquina.

Necessidades de textura

A textura é importante ao misturar cosméticos. Cremes, géis, e todos os soros precisam de misturas diferentes. Misturadores de alto cisalhamento fazem cremes suaves e sem grumos. Os misturadores V são bons para misturar pós. Os fabricantes devem testar os misturadores para descobrir qual deles oferece a melhor textura.

Limpeza & Manutenção

A limpeza fácil economiza tempo e mantém os produtos seguros. Muitas máquinas possuem sistemas de limpeza no local ou podem ser desmontadas sem ferramentas. Fazer manutenção regular evita avarias. Isso mantém a fábrica funcionando bem. Os fabricantes devem escolher máquinas que sejam fáceis de limpar.

Procure máquinas com superfícies lisas e peças de fácil acesso.

Verifique se a máquina possui certificados de limpeza.

Automação

A automação ajuda as fábricas a trabalhar mais rápido e a cometer menos erros. Muitas máquinas novas possuem controles e sensores que você pode programar. Mixers automatizados podem assistir o tempo, velocidade, e temperatura. Isso torna o processo mais confiável e fácil de repetir.

Observação: A automação pode ajudar as empresas a fabricar mais produtos sem precisar de mais trabalhadores.

Necessidades de mistura cosmética & Equipamento

Combinando equipamentos com metas de produção

Os fabricantes precisam escolher equipamento de fabricação de cosméticos que se adapta aos seus objetivos. Cada fábrica tem suas próprias necessidades. Isso depende dos produtos que eles fabricam, quanto eles ganham, e o que os clientes desejam. Algumas empresas fabricam pequenos lotes de produtos especiais. Outros precisam fazer muitos produtos o tempo todo. O equipamento certo ajuda as fábricas a trabalhar melhor e mantém a mesma qualidade.

Ao escolher equipamentos de fabricação de cosméticos, as pessoas deveriam pensar em algumas coisas:

Tamanho do lote: Misturadores pequenos são bons para laboratórios ou marcas pequenas. Misturadores grandes são melhores para fazer muitos produtos.

Tipo de Produto: Cremes, géis, e pós cada um precisa do seu próprio máquinas de mistura.

Escalabilidade: Equipamentos devem permitir que a empresa cresça mais tarde. Os sistemas modulares ajudam as fábricas a crescer com mais facilidade.

Costumização: Algumas empresas precisam de máquinas feitas de acordo com suas próprias receitas ou embalagens.

Se o sistema atende às necessidades da empresa, o trabalho vai mais rápido. Há menos desperdício e menos tempo quando as máquinas não estão funcionando. As empresas com o equipamento certo podem mudar rapidamente quando surgem novas tendências.

Considerações sobre ROI

Retorno do investimento (ROI) é muito importante na hora de escolher o equipamento. As empresas devem pensar no preço agora e na economia depois. Bons equipamentos para fabricação de cosméticos podem custar mais no início. Mas economiza dinheiro porque funciona bem e não quebra com frequência.

Alguns fatores importantes de ROI são:

Fator | Impacto é ROI |

|---|---|

Eficiência energética | Reduz custos operacionais |

Automação | Reduz despesas trabalhistas |

Durabilidade | Prolonga a vida útil do equipamento |

Flexibilidade | Suporta lançamentos de novos produtos |

Uma boa produção ajuda as empresas a ganhar mais dinheiro. Quando as fábricas funcionam melhor, mais produtos chegam às lojas mais rapidamente. Equipamentos personalizados também ajudam as empresas a acompanhar o que os clientes desejam. Pensando no custo, crescimento, e necessidades personalizadas, as empresas garantem que seus equipamentos as ajudem a crescer por um longo tempo.

Escolher a máquina misturadora de cosméticos certa ajuda uma empresa a ter um bom desempenho. Cada máquina é adequada para diferentes tamanhos de lote e produtos. Algumas máquinas funcionam melhor para determinados trabalhos ou necessidades de automação. Os fabricantes devem escolher equipamentos que se adequem ao que desejam fabricar agora e no futuro. Eles também devem pensar em como seus negócios podem crescer.

Para obter os melhores resultados, converse com fornecedores e peça demonstrações ao vivo. Você também pode obter ajuda de especialistas antes de comprar qualquer equipamento. Planejar com antecedência ajuda a garantir que seus produtos cosméticos sejam bem feitos e que sua fábrica funcione perfeitamente por um longo tempo.

Perguntas frequentes

Qual é o principal benefício de usar um misturador emulsificante a vácuo em cosméticos?

UM misturador emulsificante a vácuo torna cremes e loções suaves. O vácuo remove bolhas de ar da mistura. Isso melhora a textura e ajuda o produto a durar mais. As empresas usam esta máquina para obter sempre os mesmos resultados.

Com que frequência os fabricantes devem limpar as máquinas misturadoras de cosméticos?

Os fabricantes precisam limpar suas máquinas após cada lote. A limpeza muitas vezes impede os germes e mantém os produtos seguros. Muitos misturadores são feitos para serem fáceis de limpar ou possuem sistemas que se limpam sozinhos. Isso ajuda os trabalhadores a terminar a limpeza mais rapidamente.

Um misturador pode lidar com pós e líquidos??

Alguns misturadores, como planetário ou tipos de alto cisalhamento, pode misturar pós e líquidos. Mas as empresas devem sempre verificar se o misturador se adapta aos seus produtos. Eles precisam ver o que a máquina pode fazer antes de usá-la.

Quais certificações são importantes para equipamentos de fabricação de cosméticos?

As empresas devem procurar a ISO9001, CE, e certificações TUV. Mostram que o equipamento é seguro e atende às normas de qualidade para cosméticos.

Explorando novos locais. Qualquer amor por sclub88bet aqui? Boa seleção, probabilidades decentes? Qualquer informação apreciada. sclub88bet

JetXcasino é minha escolha para uma sessão de jogo rápida e emocionante! A interface é suave, e estou sempre encontrando novos jogos para experimentar. Recomendo dar uma olhada para se divertir e se divertir jetxcasino.