Introdução

A indústria de cuidados pessoais, particularmente o mercado de géis de banho, teve um crescimento significativo nas últimas décadas. À medida que aumentam as expectativas dos consumidores por produtos mais sofisticados e de alta qualidade, os fabricantes estão constantemente buscando métodos inovadores para melhorar seus processos de produção. Uma dessas inovações é o uso de recipientes de agitação na produção de géis de banho. Esses recipientes são essenciais para a formulação e consistência do produto final, garantindo que cada lote atenda a rigorosos padrões de qualidade. Este artigo investiga o papel crucial que os recipientes de agitação desempenham na produção de gel de banho, destacando seus benefícios, a tecnologia por trás deles, e seu impacto na qualidade do produto e na eficiência da fabricação.

O papel dos recipientes de agitação na produção de gel de banho

Agitando recipientes, também conhecidos como tanques de mistura ou tanques agitadores, são equipamentos essenciais na produção de géis de banho. Sua principal função é garantir que todos os ingredientes sejam bem misturados para obter uma solução homogênea.. Os géis de banho são formulações complexas que incluem surfactantes, hidratantes, fragrâncias, corantes, e conservantes. Conseguir uma mistura consistente destes ingredientes é crucial para a qualidade e desempenho do produto final.

Garantindo Homogeneidade

Um dos aspectos mais críticos da produção de gel de banho é a distribuição uniforme dos ingredientes.. Os recipientes de agitação são projetados para criar uma mistura consistente e homogênea, impedindo a separação de componentes. Esta uniformidade é essencial para manter a eficácia e estabilidade do gel de banho, garantindo que cada uso ofereça a mesma experiência de qualidade ao consumidor.

Controle de temperatura

Muitos ingredientes usados em géis de banho são sensíveis às mudanças de temperatura. Os recipientes de agitação são frequentemente equipados com sistemas de controle de temperatura que mantêm a temperatura ideal para mistura. Esta capacidade é particularmente importante para incorporar componentes sensíveis ao calor, como certas fragrâncias e ingredientes ativos, sem degradar sua eficácia.

Mistura Eficiente

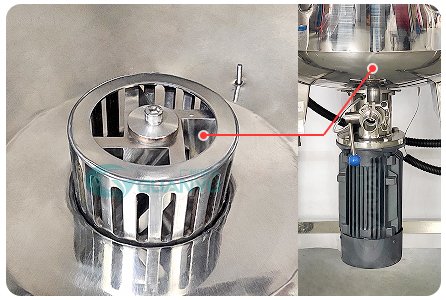

Os recipientes de agitação são projetados para lidar com a alta viscosidade das formulações de gel de banho. O uso de vários tipos de agitadores, como misturadores de turbina, misturadores de pá, e misturadores de âncora, garante que mesmo as formulações mais espessas sejam misturadas de forma eficiente. Esta eficiência não só melhora a qualidade do produto final, mas também reduz o tempo e os custos de produção.

Tecnologia por trás dos recipientes de agitação

A tecnologia utilizada nos recipientes de agitação evoluiu significativamente, incorporando recursos avançados que melhoram seu desempenho e confiabilidade. Os principais avanços tecnológicos incluem:

Agitadores de velocidade variável

Os recipientes de agitação modernos são equipados com agitadores de velocidade variável que permitem um controle preciso da velocidade de mistura. Esta flexibilidade é crucial para ajustar a intensidade da mistura com base na viscosidade da formulação e na etapa de produção. Por exemplo, velocidades mais altas podem ser usadas inicialmente para dispersar ingredientes sólidos, enquanto velocidades mais baixas são usadas durante os estágios finais para evitar aprisionamento de ar.

Sistemas de controle automatizados

A automação desempenha um papel significativo na produção moderna de gel de banho. Os recipientes de agitação são frequentemente integrados a sistemas de controle automatizados que monitoram e ajustam os parâmetros de mistura em tempo real. Esses sistemas garantem uma qualidade consistente do produto, mantendo condições ideais de mistura e reduzindo o risco de erro humano.

Projeto Sanitário

A higiene é uma prioridade máxima na produção de produtos de cuidados pessoais. Os recipientes de agitação são projetados com características sanitárias, como suave, superfícies polidas e CIP (Limpeza no local) sistemas, Para evitar contaminação. Estas características são essenciais para cumprir as regulamentações da indústria e garantir a segurança e a qualidade dos géis de banho..

Benefícios do uso de recipientes de agitação

O uso de recipientes de agitação na produção de gel de banho oferece inúmeros benefícios que contribuem para a eficiência geral e a qualidade do processo de fabricação.

Melhor qualidade do produto

Os recipientes de agitação garantem que todos os ingredientes sejam bem misturados, resultando em um produto uniforme e de alta qualidade. Esta consistência é crucial para manter a reputação da marca e satisfazer as expectativas dos consumidores.. A capacidade de controlar com precisão os parâmetros de mistura também permite que os fabricantes ajustem as formulações, criando géis de banho com propriedades sensoriais e desempenho aprimorados.

Maior eficiência de produção

A mistura eficiente reduz o tempo de produção e minimiza o desperdício. Os recipientes de agitação são projetados para lidar com grandes volumes de produto, permitindo que os fabricantes produzam géis de banho a granel sem comprometer a qualidade. O uso de sistemas de controle automatizados agiliza ainda mais o processo de produção, reduzindo a necessidade de intervenção manual e aumentando o rendimento.

Economia de custos

Os ganhos de eficiência alcançados com o uso de recipientes agitadores se traduzem em economia de custos para os fabricantes. Tempos de produção reduzidos, menor consumo de energia, e a minimização do desperdício contribuem para reduzir os custos operacionais. Adicionalmente, a capacidade de produzir consistentemente, produtos de alta qualidade reduzem o risco de recalls dispendiosos e retrabalho de produtos.

Segurança e conformidade aprimoradas

Recipientes de agitação com projetos sanitários e sistemas de controle automatizados ajudam os fabricantes a cumprir as regulamentações do setor e os padrões de segurança. Estas características reduzem o risco de contaminação e garantem que o processo de produção atenda aos rigorosos requisitos da indústria de cuidados pessoais.. Mantendo altos padrões de higiene e segurança, os fabricantes podem proteger seus funcionários e consumidores.

Estudo de caso: Implementando recipientes de agitação na produção de gel de banho

Para ilustrar o impacto dos recipientes de agitação na produção de gel de banho, considere o caso de uma empresa de cuidados pessoais de médio porte que decidiu atualizar suas instalações de fabricação. O objetivo da empresa era melhorar a qualidade do produto e aumentar a capacidade de produção para atender à crescente demanda do mercado..

Desafios Iniciais

Antes da atualização, a empresa enfrentou vários desafios, incluindo qualidade de produto inconsistente, longos tempos de produção, e altos custos operacionais. O equipamento de mistura existente teve dificuldades para lidar com a alta viscosidade das formulações de gel de banho, levando a mistura inadequada e falhas frequentes de lote. Adicionalmente, o controle manual dos parâmetros de mistura resultou em variações entre lotes.

A solução

A empresa investiu em recipientes misturadores de última geração, equipados com agitadores de velocidade variável e sistemas de controle automatizados. Esses recipientes foram projetados especificamente para produtos de alta viscosidade e apresentavam projetos sanitários para garantir a conformidade com os padrões de higiene.

Resultados

A implantação dos novos recipientes agitadores proporcionou melhorias significativas no processo produtivo:

- Consistência: Os sistemas de controle automatizado garantiram que cada lote fosse misturado em condições ideais, resultando em qualidade consistente do produto. A empresa relatou uma redução significativa nas falhas de lote e recalls de produtos.

- Eficiência: As eficientes capacidades de mistura dos novos recipientes reduziram os tempos de produção em 30%, permitindo que a empresa aumente sua produção sem adicionar turnos ou pessoal adicional.

- Economia de custos: A redução do tempo de produção e do desperdício levou a uma 20% diminuição dos custos operacionais. A empresa também se beneficiou do menor consumo de energia devido ao design eficiente dos recipientes de agitação.

- Crescimento do mercado: Com melhor qualidade do produto e maior capacidade de produção, a empresa conseguiu expandir sua presença no mercado e atender à crescente demanda por seus géis de banho.

Conclusão

O uso de recipientes de agitação na produção de gel de banho é um divisor de águas para os fabricantes que buscam melhorar a qualidade do produto e a eficiência da produção. Esses recipientes garantem a mistura completa dos ingredientes, manter condições ideais de temperatura, e reduzir tempos e custos de produção. Ao integrar recursos avançados, como agitadores de velocidade variável e sistemas de controle automatizados, os recipientes de agitação fornecem a precisão e a confiabilidade necessárias para produzir géis de banho de alta qualidade de forma consistente.

À medida que as expectativas dos consumidores continuam a evoluir, os fabricantes devem investir em tecnologias inovadoras para se manterem competitivos. Os recipientes de agitação representam um investimento crítico para qualquer empresa que pretenda melhorar os seus processos de produção e fornecer ao mercado produtos de gel de banho de qualidade superior.. Os benefícios da melhoria da qualidade do produto, maior eficiência, economia de custos, e a segurança aprimorada tornam os recipientes de agitação uma ferramenta indispensável na moderna indústria de cuidados pessoais.

Your point of view caught my eye and was very interesting. Obrigado. I have a question for you.

Your point of view caught my eye and was very interesting. Obrigado. I have a question for you.