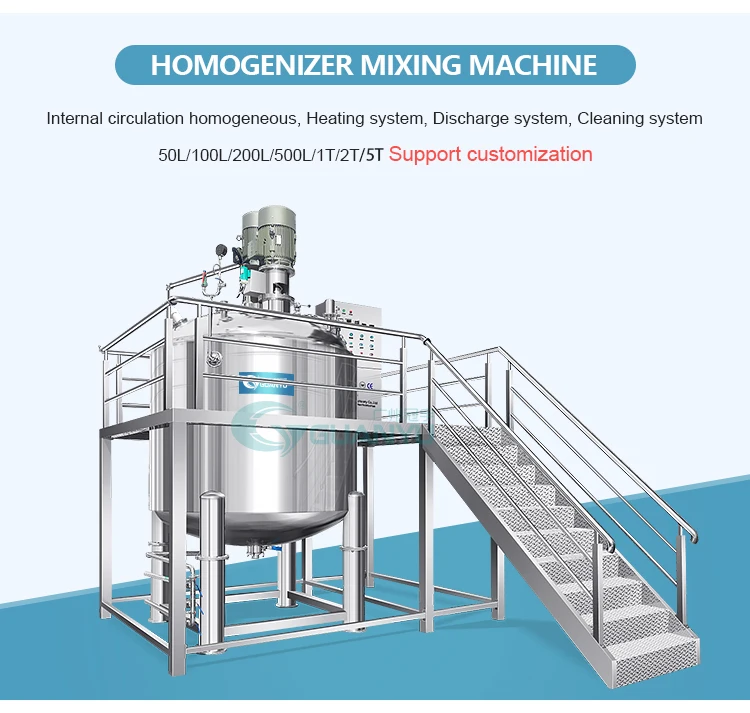

Creme elétrico de aquecimento elétrico a vácuo

Descrição dos produtos

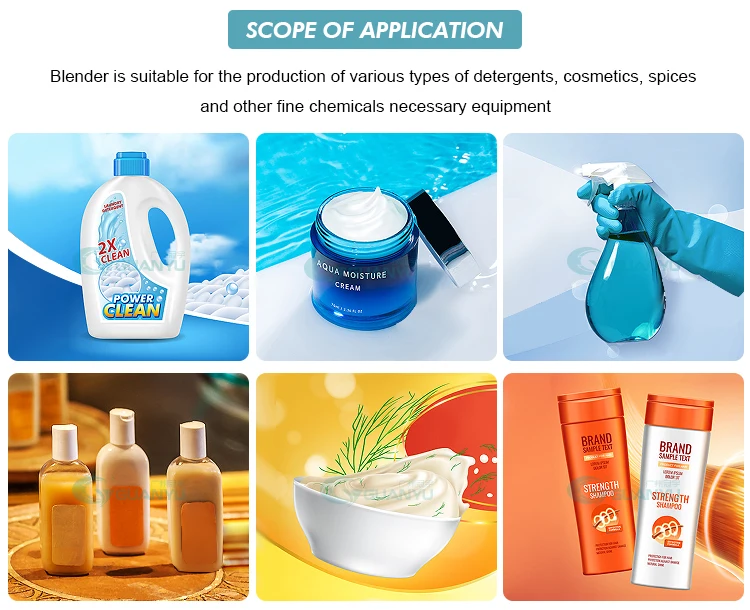

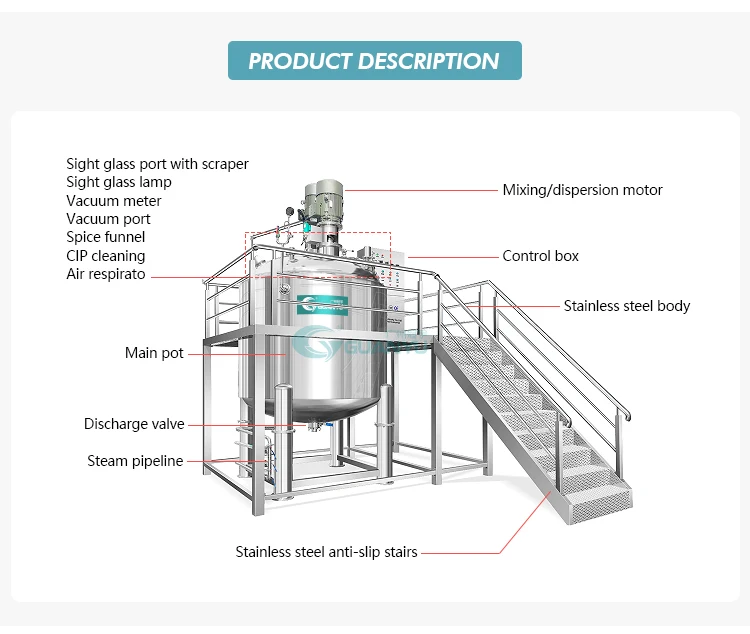

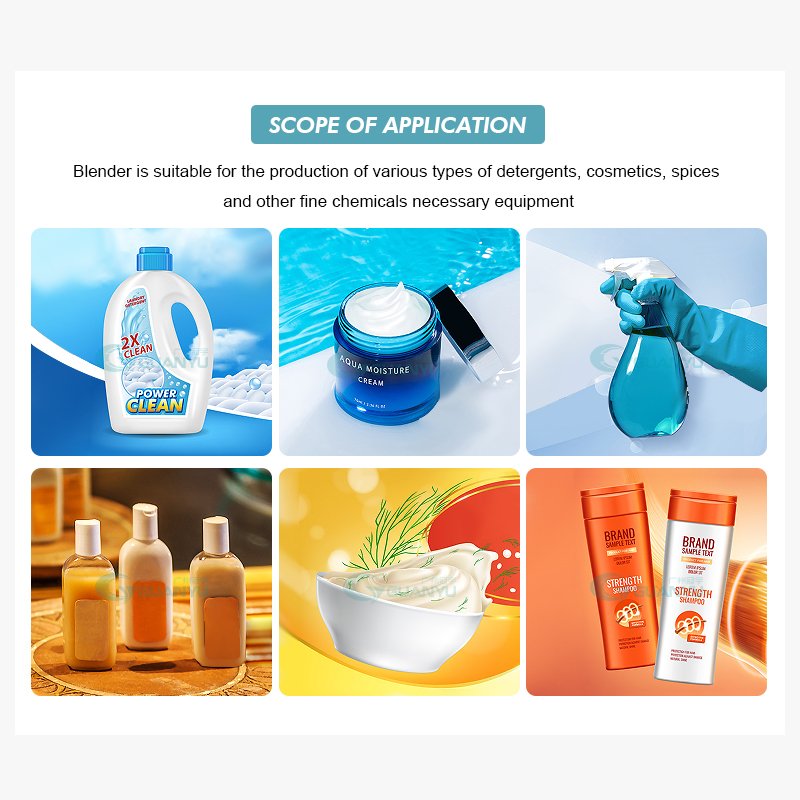

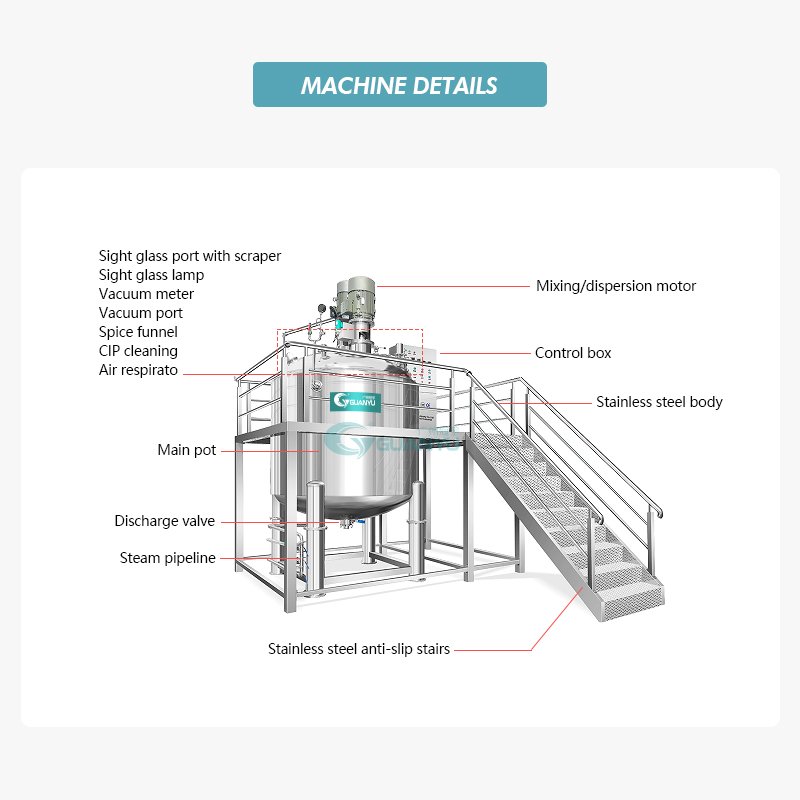

1,A mistura tripla adota o inversor de frequência importado para ajuste de velocidade,que podem atender a diferentes demandas tecnológicas.2, a estrutura homogeneizadora é feita através da tecnologia alemã. A máquina adota o efeito mecânico de ponta dupla aprimorada. A velocidade máxima de rotação emulsificante pode atingir 3500 rpm e a alta finura de cisalhamento pode atingir 0,2-5um.3, a malha de vácuo pode fazer com que os materiais atendam ao requisito de ser assetto . Os materiais a vácuo a vácuo sucking canavoid poeira.4, a tampa da caldeira principal pode adotar o sistema de elevação, É fácil de limpar e o efeito de limpeza é mais óbvio, a principal caldeira canadept tilting descarregando.5, o corpo da caldeira é soldado com 3 placa SS importada de camada, O corpo e os tubos do tanque adotam o espelho polonês que atenda ao padrão GMP.6, de acordo com o requisito do processo, o corpo do tanque pode aquecer e resfriar o aquecimento elétrico.7, para garantir a estabilidade da máquina inteira, A máquina adota os aparelhos elétricos importados que podem atender aos contratos internacionais.

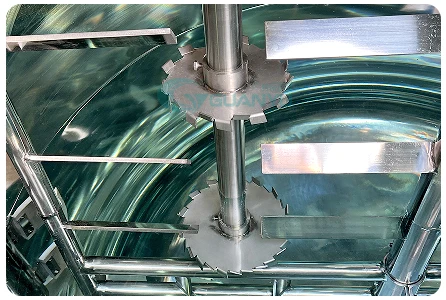

Mistura de remo

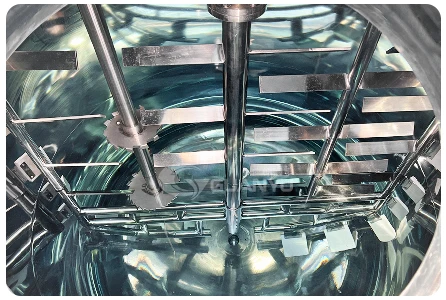

A regulação da velocidade de frequência variável é 0-62r/min, para que diferentes materiais possam ser misturados uniformemente. A forma da pá de mistura será projetada de acordo com seus materiais

Disperso

As serrilhas superior e inferior do disco de dispersão podem cisalhar, impacto, esmagar e dispersar materiais como tinta, pó seco e líquido sólido em alta velocidade, para obter uma mistura rápida, dissolução, dispersão e refinamento

Design de vedação

Design asséptico selado, Equipado com filtro de alimentação, Válvula de drenagem, espelho leve, espelho boca, essência Hopper, Limpeza de CIP, ar

respirador, usando os siemens, ABB e outros motores

respirador, usando os siemens, ABB e outros motores

Aquecimento

Aquecimento elétrico ou aquecimento a vapor podem ser selecionados, e o material é aquecido através do interclayer para alcançar o ideal

estado de agitação e emulsificação.

estado de agitação e emulsificação.

Console

A caixa de controle inclui configurações como cisalhamento homogêneo, mistura de regulação da velocidade de conversão de frequência,

tempo de trabalho, Extração de vácuo, aquecimento entre camadas, etc..

(O controle do PLC é opcional)

tempo de trabalho, Extração de vácuo, aquecimento entre camadas, etc..

(O controle do PLC é opcional)

Serviço

Use componentes de marca de renome internacional para garantir a qualidade do equipamento e uma vida útil mais longa

Avaliações

Ainda não há comentários.