5 Reator de laboratório de vidro de aço inoxidável, creme cosmético, homogeneização visual, loção emulsificante a vácuo, misturador

Descrição dos produtos

Nossas vantagens:

◭ 25 Anos: Guangzhou Guanyu Machinery Co.LTD está envolvido em pesquisa e fabricação de máquinas para medicina, alimentos e produtos químicos industriais para 25 anos.

◭ Nossa própria fábrica: Nossa fábrica tem 7000 metros quadrados, mais do que 100 trabalhadores, e 6 Linhas de produção de máquinas, incluindo fabricação de máquinas, polimento, e teste.

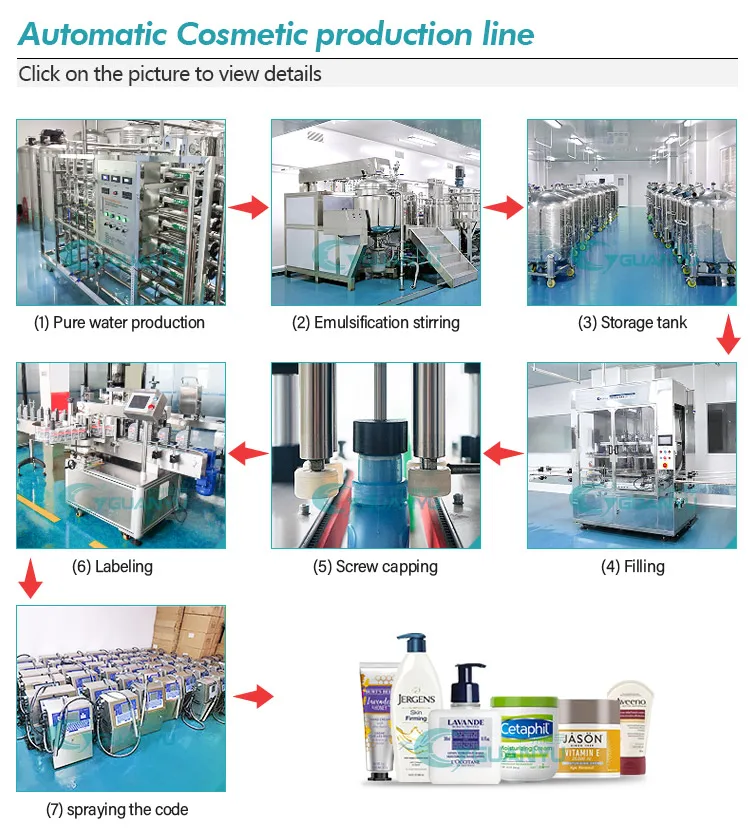

◭ Máquinas personalizadas: Nossos principais produtos incluem máquinas emulsificantes de vácuo fixas, homogeneizadores móveis, Todos os tipos de chaleiras agitadoras de reação.

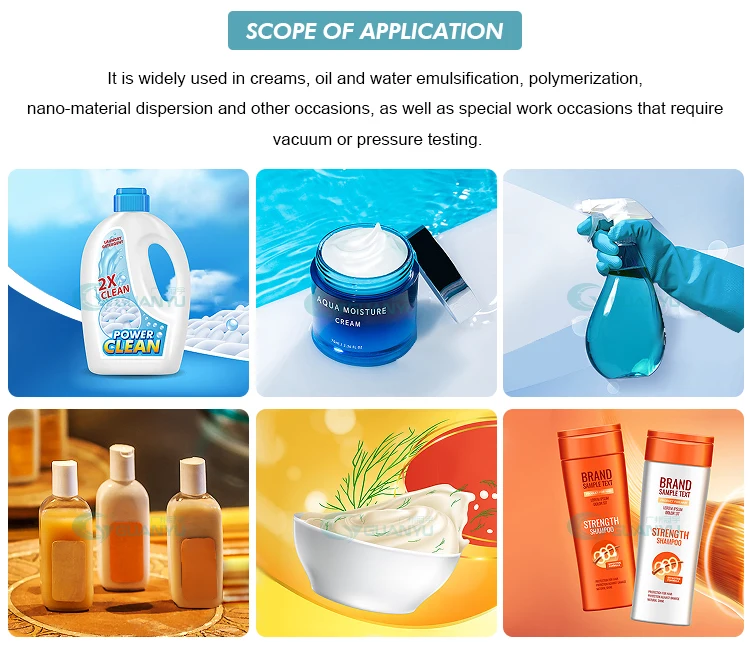

◭ Produtos aplicáveis: Eles são adequados para fazer creme, loção, produtos líquidos, incluindo creme para o rosto, pomadas, ketchup, maionese, Jam, sabonete, shampoo etc..

◭ Certificações: CE, GMP, UL e certificados de tecnologia patenteados.

Todas as máquinas são personalizadas para você!

◭ Nossa própria fábrica: Nossa fábrica tem 7000 metros quadrados, mais do que 100 trabalhadores, e 6 Linhas de produção de máquinas, incluindo fabricação de máquinas, polimento, e teste.

◭ Máquinas personalizadas: Nossos principais produtos incluem máquinas emulsificantes de vácuo fixas, homogeneizadores móveis, Todos os tipos de chaleiras agitadoras de reação.

◭ Produtos aplicáveis: Eles são adequados para fazer creme, loção, produtos líquidos, incluindo creme para o rosto, pomadas, ketchup, maionese, Jam, sabonete, shampoo etc..

◭ Certificações: CE, GMP, UL e certificados de tecnologia patenteados.

Todas as máquinas são personalizadas para você!

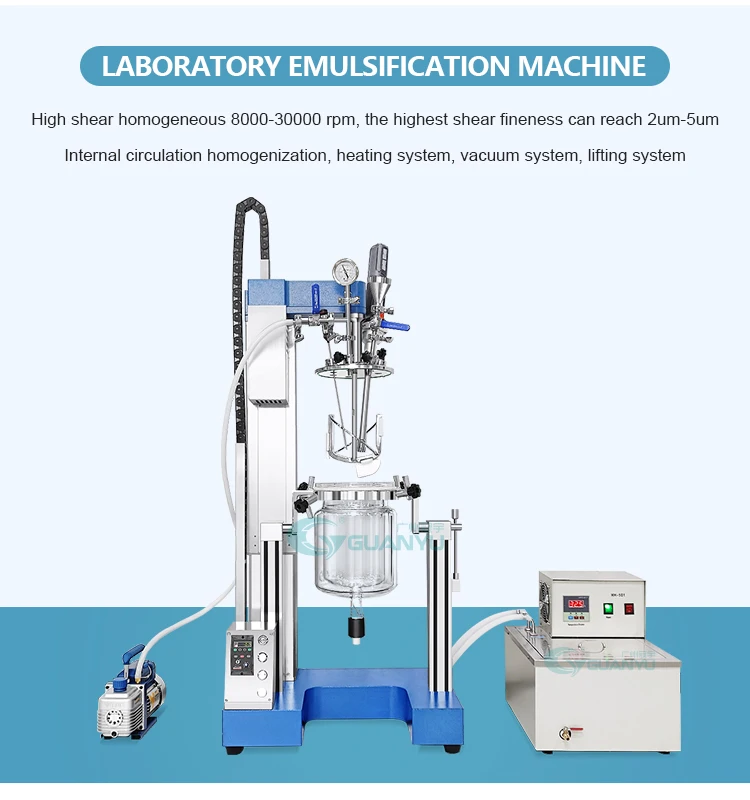

5 Litro de vidro aço inoxidável reator laboratório cosméticos creme homogeneização visual emulsificador lition vácuo emusifying mxier

5 Litro de vidro aço inoxidável reator laboratório cosméticos creme homogeneização visual emulsificador lition vácuo emusifying mxier

Fonte de energia | 220V (pode ser personalizado) |

Vácuo final | -0.08MPA |

Velocidade de agitação | 0-200 RPM |

Velocidade homogeneizadora | 8000-30000 RPM |

Temperatura de trabalho | 120 |

Eu posso | Vidro opcional ou aço inoxidável |

Capacidade | Opcional 1L/5L/10L |

Conjunto

1: Motor importado da Alemanha

2: Medidor de pressão de vácuo

3: Funil de alimentação

4: Medidor de teste de temperatura em tempo real

2: Medidor de pressão de vácuo

3: Funil de alimentação

4: Medidor de teste de temperatura em tempo real

Homogeneizador

1: Cisalhamento homogêneo de alta velocidade,8000-30000 RPM

2: Detecção de temperatura em tempo real por sonda de temperatura

3: Nenhum canto morto raspando e mexendo, 0-200 RPM

2: Detecção de temperatura em tempo real por sonda de temperatura

3: Nenhum canto morto raspando e mexendo, 0-200 RPM

1.A placa de raspagem de politetrafluroetileno atende ao corpo da ranhura de mistura e raspa o material de viscosidade na parede da caldeira.

2.O homogeneizador é instalado no fundo da caldeira para aumentar a energia do motor de maneira mais completa e fortemente. Durante algumas produções, pode exercer efeito homogeneizador totalmente.

3.Rotor da curva isotática de equilíbrio da poder,Rubbing.Centrifugal para garantir que o creme requintado e liso; Polimento de espelho do corpo e superfície do tubo de caldeira 300emsh(Grau de saneamento) Acordo com a regulamentação química e GMP diária.

Painel de controle

Controle de mixagem (regulação de velocidade infinita),

controle do sistema de elevação,

controle do sistema de vácuo

controle do sistema de elevação,

controle do sistema de vácuo

Bombas a vácuo

Adotando sucção a vácuo para materiais em pó para evitar o vôo de poeira. Também pode evitar a formação de bolhas após mistura em alta velocidade, e é usado para remover bolhas, atendendo aos requisitos de higiene e esterilidade

Dispositivo de aquecimento

Usando bombas de água de alta qualidade como energia circulante, o problema da temperatura irregular da água está resolvido. temperatura

faixa de controle: temperatura ambiente +5~100°C

faixa de controle: temperatura ambiente +5~100°C

Chaleira de reação de vidro

O processo de reação de agitação, homogeneização, emulsificação, dispersão, e a mistura de materiais pode ser observada em tempo real através de uma chaleira de vidro

Avaliações

Ainda não há comentários.