SHAMPOO DE COMPRIMENTO DE MISTRA DE MISTRA DE MISTURA DE MISTURA DE MISTURA DE MISTÓRIA DE MÁQUIO DE MACHIA REAÇÃO DE MÁQUICA REAÇÃO COM MÁQUICA REAÇÃO QUÍMICA

Descrição dos produtos

Modelo | Eficaz | Poder de agitação e velocidade | Poder e velocidade homogêneos | Poder de aquecimento | |||

Capacidade | KW | R/min | KW | R/min | Aquecimento elétrico | Aquecimento a vapor | |

GY-50 | 50 | 0.75 | 0-65 | 3 | 3600 | 6KW | Conservação de energia de aquecimento a vapor e proteção ambiental, selecionado de acordo com a necessidade |

GY-100 | 100 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | |

GY-150 | 150 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | |

GY-200 | 200 | 1.5 | 0-65 | 3 | 3600 | 18KW | |

GY-300 | 300 | 1.5 | 0-65 | 3 | 3600 | 18KW | |

GY-500 | 500 | 2.2 | 0-65 | 4 | 3600 | 27KW | |

GY-1000 | 1000 | 4 | 0-65 | 7.5 | 3600 | 36KW | |

GY-1500 | 1500 | 4 | 0-65 | 11 | 3600 | 45KW | |

GY-2000 | 2000 | 5.5 | 0-65 | 11 | 3600 | Recomende o aquecimento a vapor | |

GY-3000 | 3000 | 7.5 | 0-65 | 15 | 3600 | ||

GY-5000 | 5000 | 11 | 0-65 | 22 | 3600 | ||

Os parâmetros apenas para referência, Todas as máquinas podem ser personalizadas de acordo. |

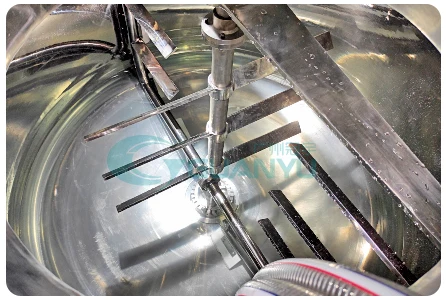

Mistura de remo

Regulação da velocidade de conversão de frequência 0-62r/min, A forma das lâminas será projetada de acordo com seus materiais.

Homogeneizador

Regulação da velocidade de conversão de frequência 0-3000R/min, Materiais de cisalhamento de alta velocidade na cabeça de cisalhamento homogêneo, para que os materiais estejam completamente quebrados e misturados!

Vácuo hermético

A falta do sistema de vácuo pode atender aos requisitos para o produto asséptico e de alto padrão.

Transporte

Equipado com uma plataforma de elevação, qual

pode ser usado para transportar materiais pesados

para a plataforma para a próxima operação.

pode ser usado para transportar materiais pesados

para a plataforma para a próxima operação.

Console

O painel de controle exibe e controla

a temperatura do equipamento, Mistura,

homogeneização, dados de pressão, etc.. em real

tempo.

( Controle opcional de PLC )

a temperatura do equipamento, Mistura,

homogeneização, dados de pressão, etc.. em real

tempo.

( Controle opcional de PLC )

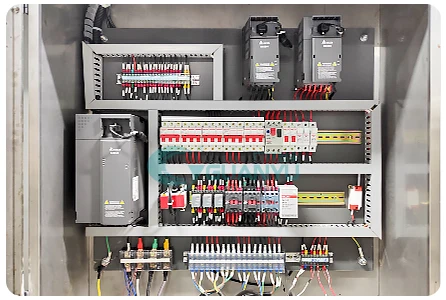

Caixa elétrica

Use uma marca de renome internacional

componentes para garantir a qualidade do

equipamento e vida útil mais longa

componentes para garantir a qualidade do

equipamento e vida útil mais longa

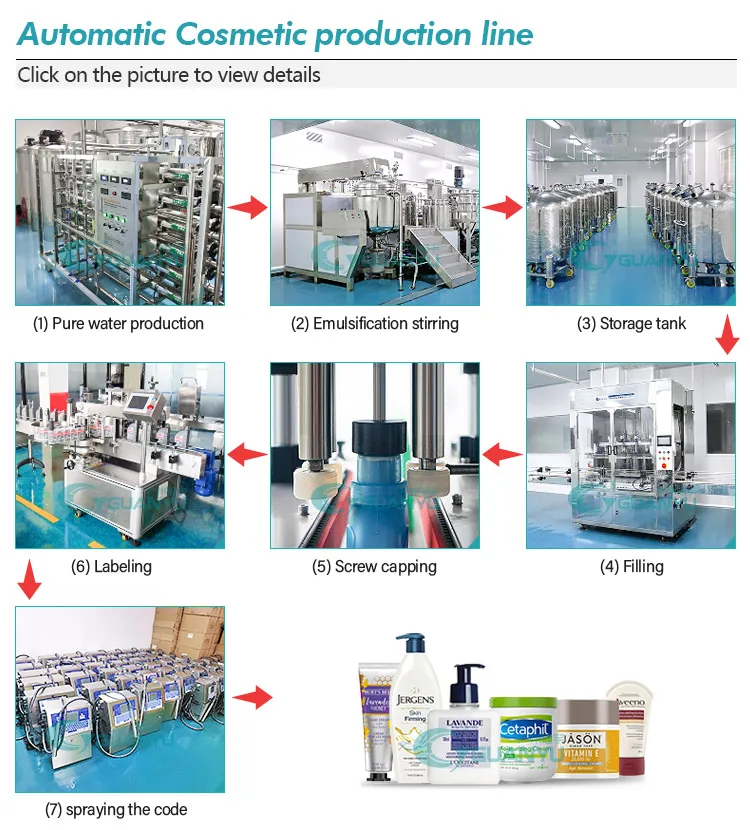

Serviço

Vamos projetar desenhos de acordo com o seu

requisitos e fornecer soluções de um funcionamento.

requisitos e fornecer soluções de um funcionamento.

Configuração do produto

Sobre nós

Processo de caso bem -sucedido

Certificações

Perguntas frequentes

Avaliações

Ainda não há comentários.