Misturador de detergente e shampoo homogeneizador para lavagem líquida, máquina para fazer tanque de mistura de sabão líquido químico

Configuração do produto

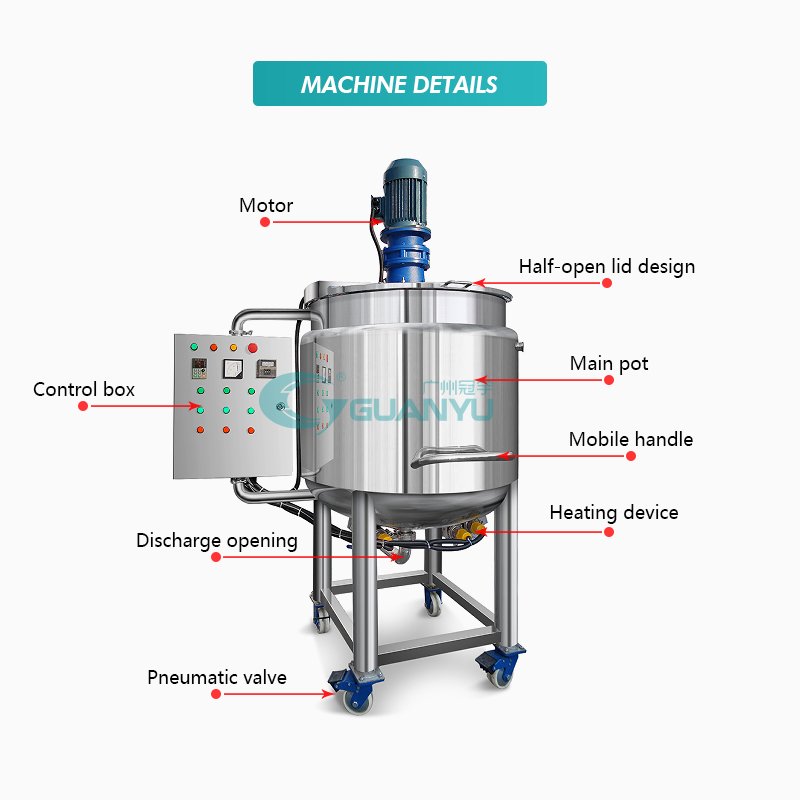

Podemos projetar os desenhos de acordo com seus requisitos | |

Volume do tanque | De 50L até 5000L ( Personalizado ) |

Material | 304 ou 316 Aço inoxidável |

Isolamento | Camada única ou com isolamento |

Tipo de cabeça superior | Top de prato, Top de tampa aberta, Top plana |

Tipo inferior | Fundo de prato, Fundo cônico, Fundo plano |

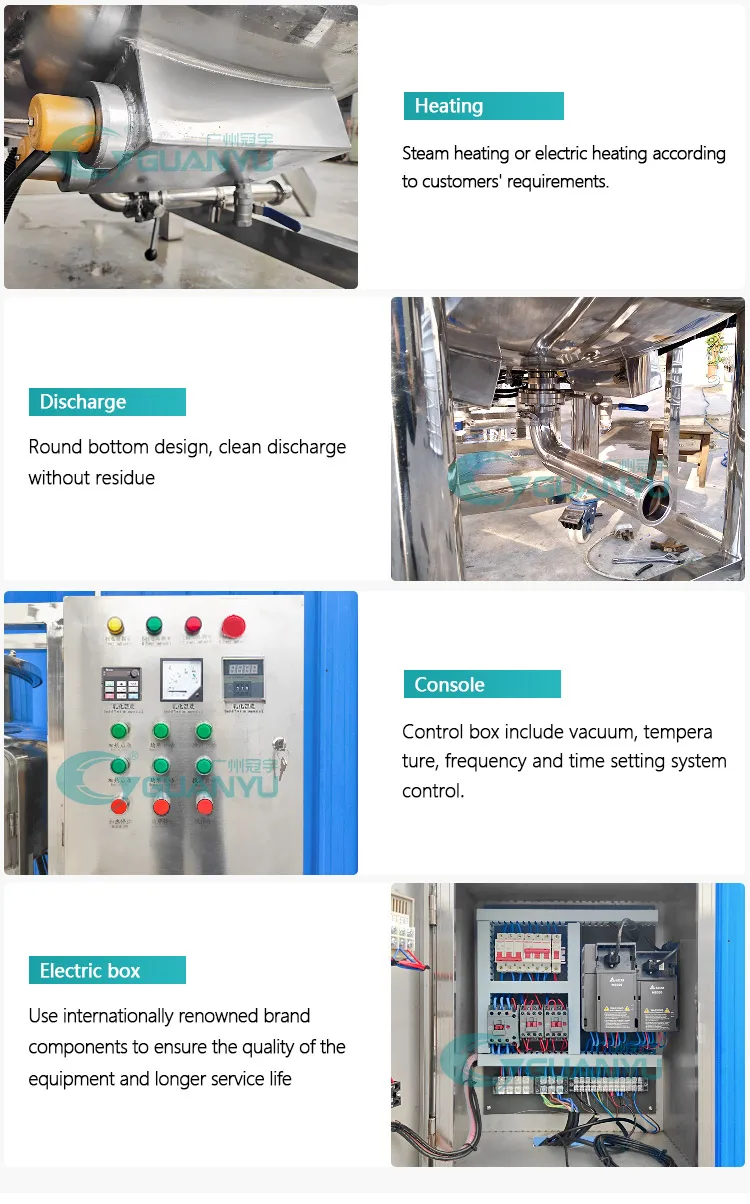

Maneira de aquecimento | Aquecimento a vapor ou aquecimento de eletricidade |

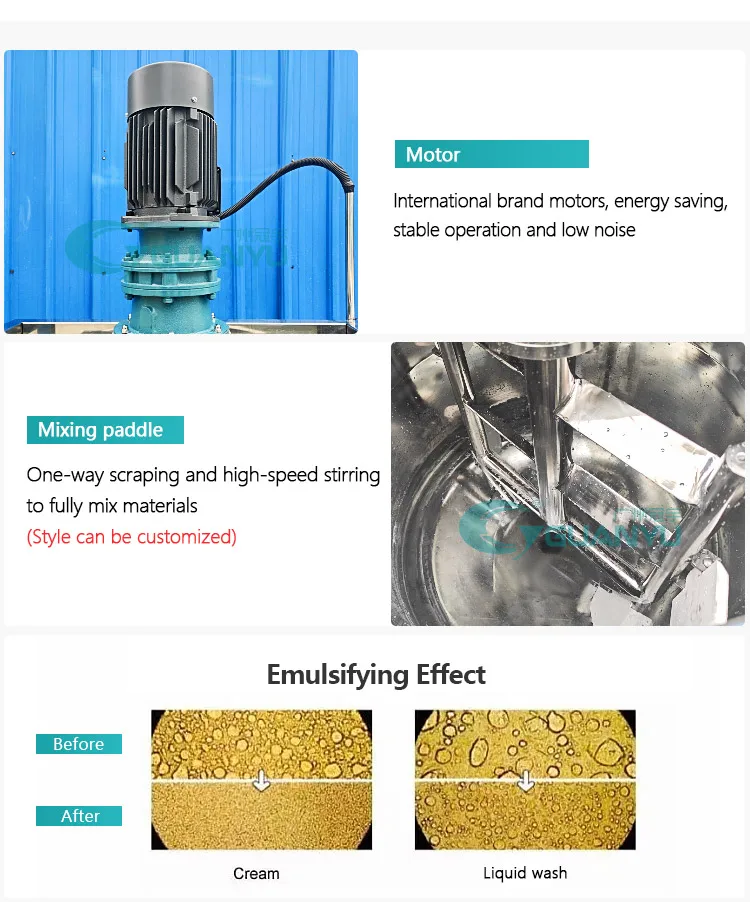

Tipo de agitador | Tipo de hélice, Tipo de âncora, Tipo de raspador, etc.. |

Poder | As superfícies internas e externas são polidas ou acabamento fosco ou fosco. |

Tensão | 415V/380V/3/50Hz, 220V/3/60Hz. |

Aplicativo | Comida, Bebida, farmácia, biológico |

mel, chocolate, álcool, indústria química etc. |

Performances e recursos-a mistura de raspagem de parede geral adota o conversor de frequência para ajuste de velocidade , para que produtos de alta qualidade de diferentes processos de acordo com os requisitos do cliente. ◭O homogeneizador diversificado de alta velocidade pode misturar poderosamente matérias-primas sólidas e líquidas e pode dissolver rapidamente muitos materiais indidissolúveis, como os AES , AESA , LSA , etc.. Durante o processo de produção de detergente líquido, a fim de economizar energia da Consumpion e o período de produção. O corpo da panela é soldado por placa de aço inoxidável de três camadas importada. O corpo do tanque e os tubos adotam polimento de luxo , que estão em conformidade com os requisitos de GMP.◭dinging to requisito do cliente , O tanque pode aquecer e resfriar materiais. O caminho do aquecimento, incluindo aquecimento a vapor e aquecimento elétrico. Fácil de descarregar , descarga direta inferior ou por bomba de transferência.

Avaliações

Ainda não há comentários.