500L jaqueta tanque de mistura de aquecimento para soros homogeneizador misturador sabão líquido que faz a máquina combinação máquina de mistura

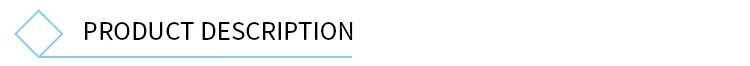

Velocidade de mistura | Velocidade variável 0 ~ 63rpm |

Velocidade homogeneizadora | Velocidade variável 0 ~ 3500rpm |

Marca de motor | Siemens/Abb |

Conversor | Siemens/Mitsubishi/Delta |

Controlador de temperatura | Omron/chnt/delixi/etc. |

Tipo de controle | Manual do botão PLC/elétrico |

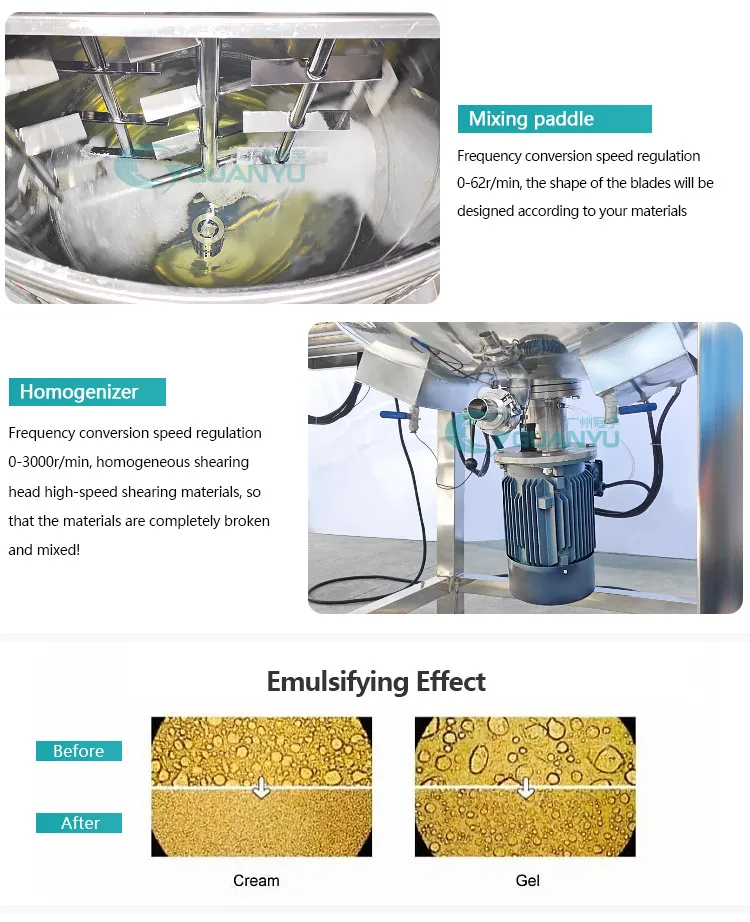

Material | Aço inoxidável 316/304/304 |

Método de aquecimento | Aquecimento elétrico/aquecimento a vapor |

Método de resfriamento | Tap água/água do resfriador |

Capacidade | 50~ 5000l(Projetado personalizado) |

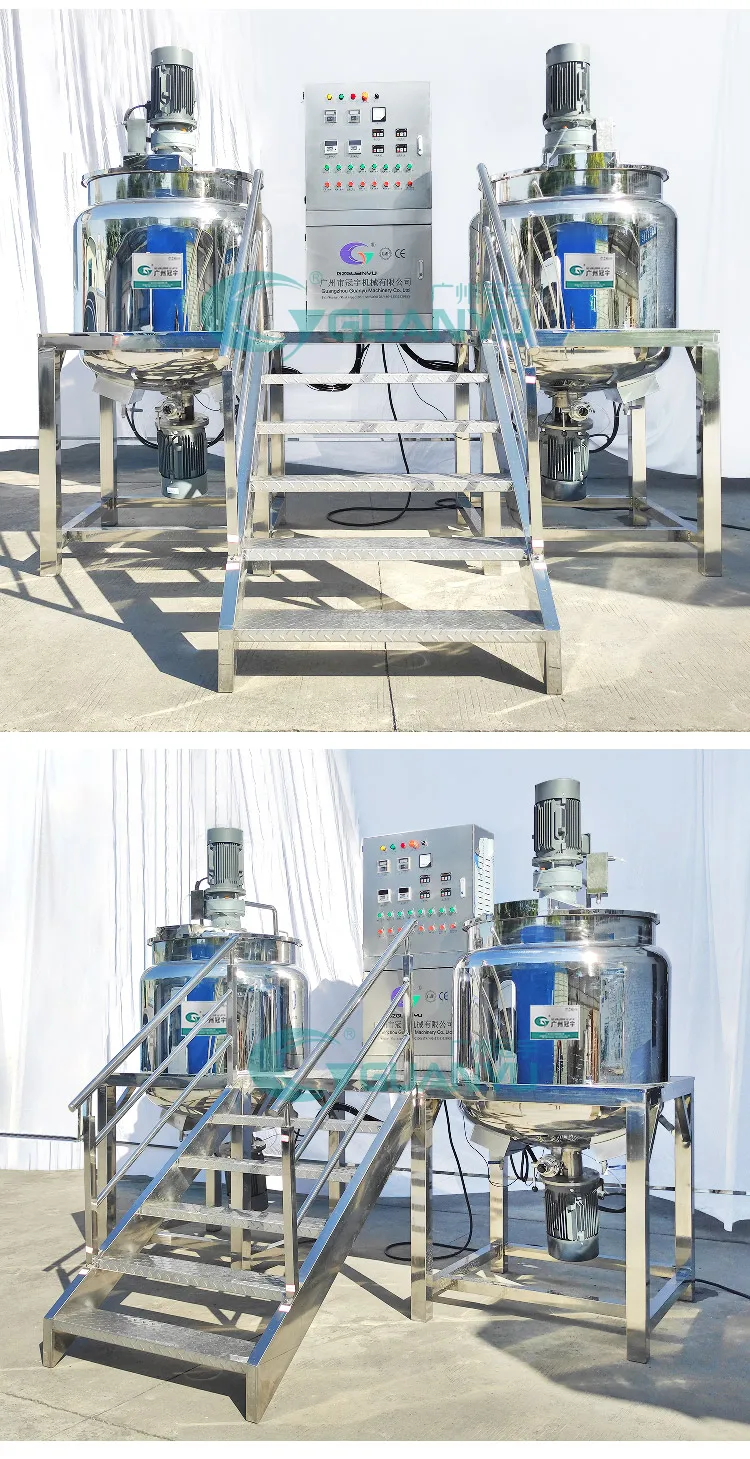

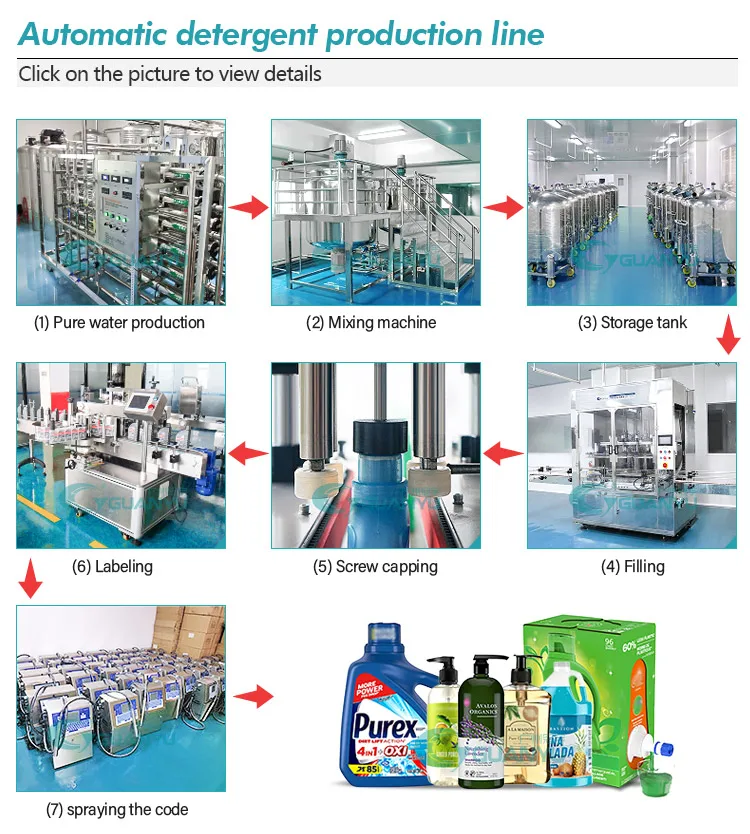

Aplicativo | Creme /loção de cosméticos / gel / xampu / sabão líquido /detergente / maionese / ketchup /etc. |

Tipo de capa | Aberto/não aberto |

Tipo de descarga | Descarga inferior |

◭A mistura de raspagem de parede geral adota o conversor de frequência para ajuste de velocidade , para que produtos de alta qualidade processos diferentes de acordo com os requisitos do cliente.

◭O homogeneizador diversificado de alta velocidade pode misturar matérias-primas sólidas e líquidas e pode dissolver rapidamente muitos materiais indidissolúveis, como AES , AESA , LSA , etc.. Durante o processo de produção de detergente líquido, de modo a economizar energia e reduzir o período de produção.

◭O corpo da panela é soldado por placa de aço inoxidável de três camadas importadas. O corpo do tanque e os tubos adotam polimento de luxo , que estão totalmente em conformidade com os requisitos de GMP.

◭Dorando a exigência do cliente , O tanque pode aquecer e resfriar materiais. O caminho do aquecimento, incluindo aquecimento a vapor e aquecimento elétrico. Fácil de descarregar , descarga direta inferior ou por bomba de transferência.

Nosso serviço1.Tempo de garantia:um ano, A partir da data em que o produto é qualificado comissionamento. Qualquer dano, exceto a operação errada durante o período de garantia, é reparado livremente. Mas as despesas de viagem e hotéis devem contar com o comprador.2. Serviços de comissionamento:a instalação e o comissionamento do produto no lado da demanda, Nossos engenheiros não sairão lá até obter seu contrato.3.Teringing Services: Nossos engenheiros treinarão sua equipe para operá -lo durante o período de instalação e comissionamento, e eles não sairão de lá até que sua equipe possa operá-lo de maneira adequada e normal.4.Serviços de manutenção: Qualquer mau funcionamento aconteceu, Depois de nos perguntar, Nós responderemos você dentro 48 horas, exceto os motivos especiais.5. Lifelong Services: Fornecemos serviços ao longo da vida para todos os produtos que esgotamos, e forneça as peças de reposição com descontoPrice.6.Certificate Services:Podemos fornecer certificados relacionados aos clientes livremente de acordo com a solicitação de clientes.7.Inspeção Serviços: você pode pedir à empresa de inspeção de terceira parte ou ao seu inspetor para inspecionar os produtos antes da remessa.8.O arquivo: a especificação manual, Relatório do material usado no equipamento e outros documentos relacionados às informações de autenticação GMP serão fornecidos por nós.

RFQ

1 .Q Você aceita um pedido especial? UM: Sim ,nós fazemos ; Podemos fabricar todos os tipos de equipamentos químicos de acordo com seus desenhos técnicos; 2.Q: Você pode nos dar uma citação agora? UM: Por favor, dê -nos os detalhes do técnico para que projetaremos e citamos para você o mais rápido possível;3.Q: Você tem um em estoque? UM:Desculpe. Nós não. Todos os produtos são fabricados de acordo com a necessidade do cliente;4.Q: Você pode fazer um design para nós? UM:Sim, podemos o que fornecemos não é apenas produto, mas também solução e design;5.Q:Seu engenheiro pode vir ao nosso lugar para guias de instalação? UM:Sim, nós podemos fornecer um vídeo e um documento para instalação;Se você ainda tiver problemas, enviaremos nosso engenheiro para o guia de instalação para o engenheiro; Para suas perguntas, por favor, avise -nos: 1. Quais são seus produtos? Creme,Pagado dentário, hidratante,Creme noturno, Creme de desaparecimento,SunCream etc.. 2. Qual é a capacidade que você deseja para esta máquina emulsificante a vácuo? 100eu,200L300L,500eu,1000eu, etc.. 3. Método de aquecimento necessário: aquecimento elétrico ou aquecimento a vapor? 4. Tensão necessária e frequência de fonte de alimentação? por exemplo:380V 50Hz 3fase? 5. 5. Requisito de certificado (CE, Ul, CSA, ou sem necessidade)

Avaliações

Ainda não há comentários.