Fábrica de fabricação de fábrica A vácuo emulsificante tanque de misturador para cosméticos compõem o processo de machine de mistura homogênea

Descrição dos produtos

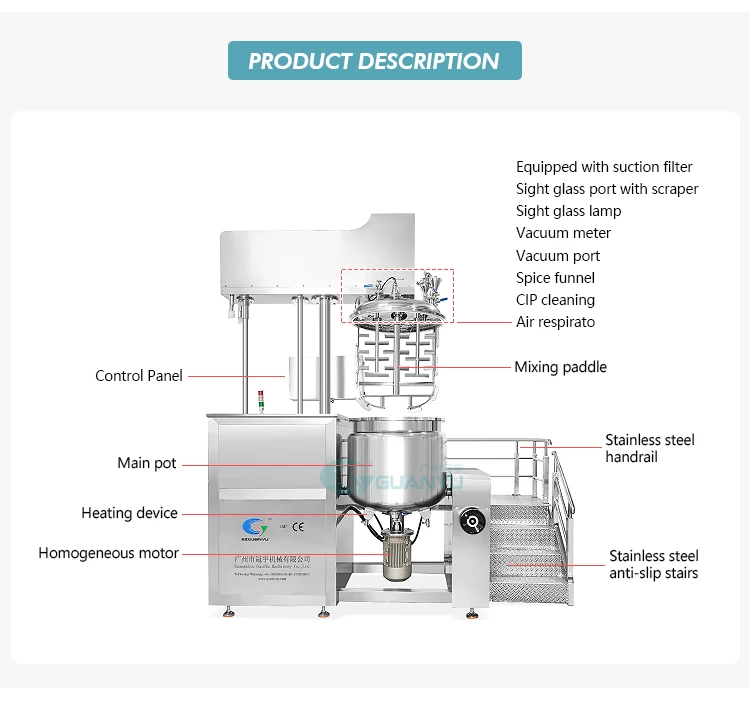

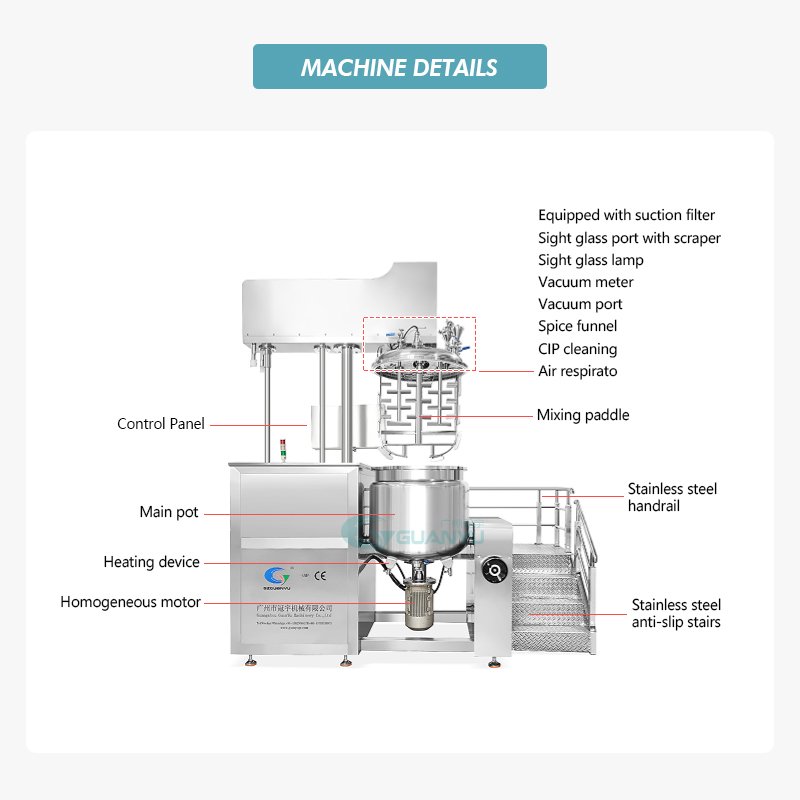

Mistura de remo

A regulação da velocidade de frequência variável é 0-62r/min, para que diferentes materiais possam ser misturados uniformemente. A forma da pá de mistura será projetada de acordo com seus materiais

Homogeneizador

Regulação da velocidade de conversão de frequência 0-3200R/min, Materiais de cisalhamento de alta velocidade na cabeça de cisalhamento homogêneo, para que os materiais estejam completamente quebrados e misturados!

Acessórios

Material SS316, grossura 6 mm,Equipado com filtro de sucção, Válvula de drenagem, porta a vácuo, Lâmpada de vidro de mira, Porta de vidro de visão com raspador, funil de especiarias, Limpeza de CIP, Respirador de ar

Pote de água-água

O tanque de fase aquática e o tanque de fase oleosa do sistema de pré-tratamento pré-aquecem e dispersam as matérias-primas, Em seguida, transfira -os para o tanque principal, e comece a mistura homogênea para emulsificar os materiais

Console

A caixa de controle inclui configurações como cisalhamento homogêneo, mistura de regulação da velocidade de conversão de frequência,

tempo de trabalho, Extração de vácuo, aquecimento entre camadas, etc..

tempo de trabalho, Extração de vácuo, aquecimento entre camadas, etc..

Console

Vamos projetar desenhos de acordo com seus requisitos e fornecer soluções de um balcão.

1. Por que nos escolher?

1.1- Nós terminamos 30 Experiência de anos em fabricação de máquinas .

1.2- Nossa fábrica está localizada em Guangzhou e outra está na província de Jiangsu,mais do que 200 trabalhadores em nossa fábrica .

1.3- Vendemos máquinas de boa qualidade em todo o mundo com bom serviço e obtivemos alta reputação de nosso cliente. Bem -vindo para visitar nossa fábrica!

1.1- Nós terminamos 30 Experiência de anos em fabricação de máquinas .

1.2- Nossa fábrica está localizada em Guangzhou e outra está na província de Jiangsu,mais do que 200 trabalhadores em nossa fábrica .

1.3- Vendemos máquinas de boa qualidade em todo o mundo com bom serviço e obtivemos alta reputação de nosso cliente. Bem -vindo para visitar nossa fábrica!

2.Você pode personalizar a máquina ?

Como fabricante profissional de máquinas para mais de 30 anos,Temos técnica de OEM qualificada.3. Que tal serviço pós -venda?

Engenheiro irá para a fábrica do comprador para instalar, máquinas de teste, e treinar funcionários do comprador como operar, maintain machines.

When machine has problem, Vamos resolver perguntas básicas por telefone, e-mail, Whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. Se o problema puder ser facilmente resolvido , Enviaremos uma solução por vídeo ou fotos. Se o problema fora do seu controle, we will arrange engineer to your factory.

Como fabricante profissional de máquinas para mais de 30 anos,Temos técnica de OEM qualificada.3. Que tal serviço pós -venda?

Engenheiro irá para a fábrica do comprador para instalar, máquinas de teste, e treinar funcionários do comprador como operar, maintain machines.

When machine has problem, Vamos resolver perguntas básicas por telefone, e-mail, Whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. Se o problema puder ser facilmente resolvido , Enviaremos uma solução por vídeo ou fotos. Se o problema fora do seu controle, we will arrange engineer to your factory.

4.How about warranty and spare parts?

Nós fornecemos 1 garantia de ano e peças de reposição suficientes para a máquina,e a maioria das peças pode ser encontrada no mercado local também,Além disso, você pode comprar de nós se todas as peças que passaram por 1 ano de garantia.

5. Como você pode controlar a qualidade e a entrega?

Todas as nossas máquinas serão testadas antes da embalagem. O ensino de vídeo e as fotos de embalagem serão enviadas a você para verificar,Prometemos que nossa embalagem de madeira é forte o suficiente e a segurança para uma entrega longa .

6. E quanto ao tempo de entrega?

Na máquina de estoque:1-7dias

Geralmente 7-60 Dias úteis(dependeu dos produtos).

Avaliações

Ainda não há comentários.