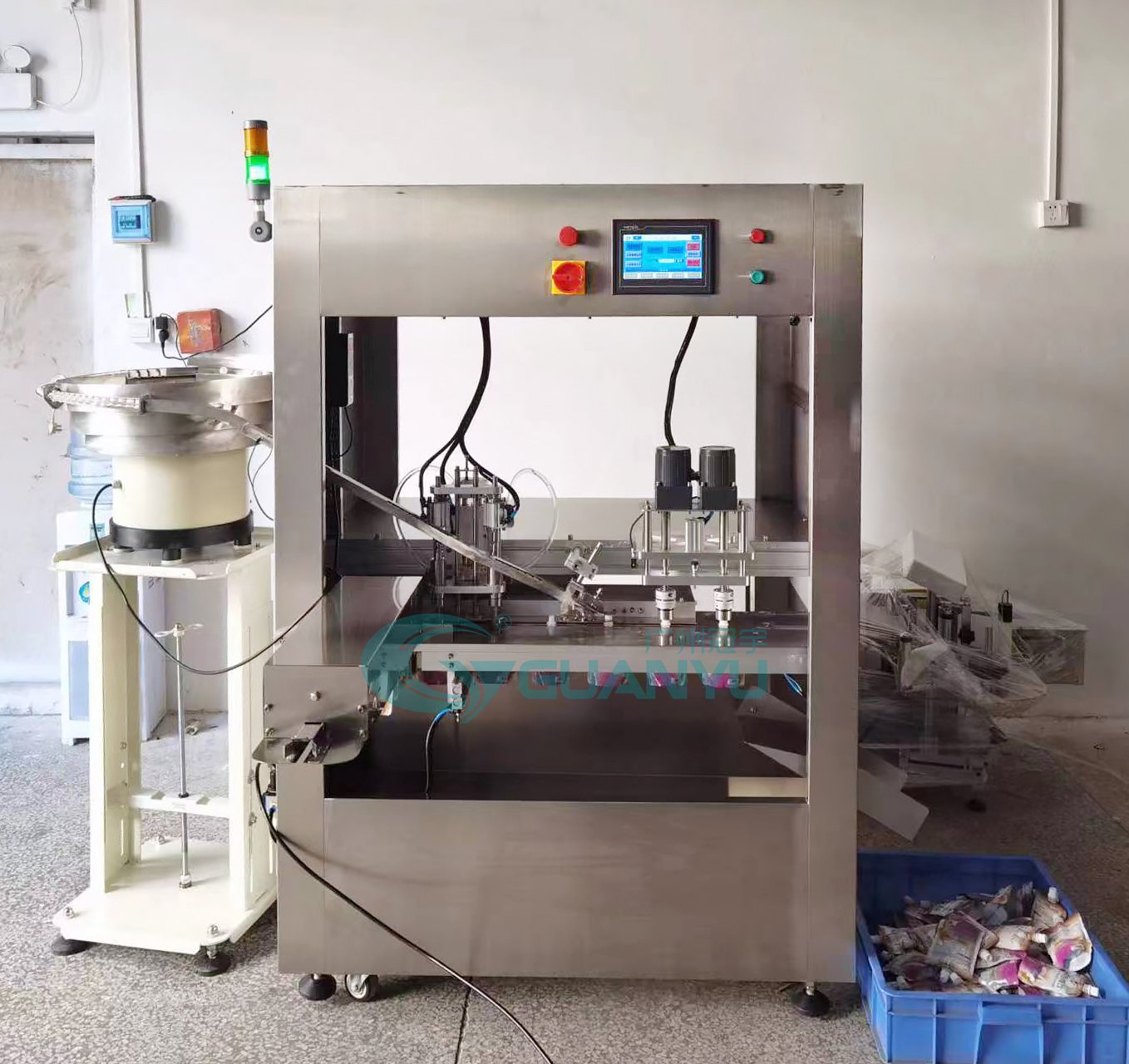

Máquina de preenchimento e tampa de bico de cabeça dupla

O Máquina de enchimento e tamponamento de bolsas com bico de cabeça dupla foi projetado para executar múltiplas tarefas simultaneamente, reduzindo significativamente o tempo necessário para operações de embalagem. Abaixo estão as principais funções da máquina:

1. Preenchimento Automático

Uma das características marcantes desta máquina é a sua sistema de enchimento de cabeça dupla. Isso permite que a máquina encha duas bolsas de bico ao mesmo tempo, dobrando a produção em comparação com máquinas de cabeçote único. O processo de enchimento é preciso, graças aos sistemas de dosagem avançados que garantem que cada embalagem seja preenchida com a quantidade exata de produto. Essa precisão ajuda a reduzir o desperdício de produtos e garante que cada embalagem atenda aos padrões exigidos.

2. Limite automático

Após o processo de enchimento, a máquina faz uma transição perfeita para o estágio de nivelamento. As bolsas de bico são tampadas automaticamente, garantindo uma vedação apertada e segura que evita vazamentos. O mecanismo de tampamento foi projetado para lidar com vários tamanhos e formatos de tampas, tornando a máquina adaptável a diferentes requisitos de embalagem. Esta automação reduz a necessidade de intervenção manual, aumentando assim a produtividade e reduzindo os custos trabalhistas.

3. Precisão e Controle

A máquina está equipada com um interface homem-máquina (HMI), normalmente na forma de uma tela sensível ao toque, permitindo que os operadores definam e ajustem facilmente parâmetros como volume de enchimento, velocidade de limite, e mais. O sistema geralmente é controlado por um controlador lógico programável (CLP), o que garante que todas as operações sejam sincronizadas e funcionem sem problemas. Este nível de controle permite que os fabricantes ajustem a máquina para diferentes produtos, garantindo consistência e qualidade em lotes.

4. Fluxo de trabalho eficiente

O design da máquina suporta um fluxo de trabalho contínuo, onde as bolsas se movem perfeitamente de uma etapa do processo para a próxima. Isso reduz gargalos e tempo de inatividade, aumentando ainda mais a eficiência da linha de produção.

O Máquina de enchimento e tamponamento de bolsas com bico de cabeça dupla foi projetado para executar múltiplas tarefas simultaneamente, reduzindo significativamente o tempo necessário para operações de embalagem. Abaixo estão as principais funções da máquina:

1. Preenchimento Automático

Uma das características marcantes desta máquina é a sua sistema de enchimento de cabeça dupla. Isso permite que a máquina encha duas bolsas de bico ao mesmo tempo, dobrando a produção em comparação com máquinas de cabeçote único. O processo de enchimento é preciso, graças aos sistemas de dosagem avançados que garantem que cada embalagem seja preenchida com a quantidade exata de produto. Essa precisão ajuda a reduzir o desperdício de produtos e garante que cada embalagem atenda aos padrões exigidos.

2. Limite automático

Após o processo de enchimento, a máquina faz uma transição perfeita para o estágio de nivelamento. As bolsas de bico são tampadas automaticamente, garantindo uma vedação apertada e segura que evita vazamentos. O mecanismo de tampamento foi projetado para lidar com vários tamanhos e formatos de tampas, tornando a máquina adaptável a diferentes requisitos de embalagem. Esta automação reduz a necessidade de intervenção manual, aumentando assim a produtividade e reduzindo os custos trabalhistas.

3. Precisão e Controle

A máquina está equipada com um interface homem-máquina (HMI), normalmente na forma de uma tela sensível ao toque, permitindo que os operadores definam e ajustem facilmente parâmetros como volume de enchimento, velocidade de limite, e mais. O sistema geralmente é controlado por um controlador lógico programável (CLP), o que garante que todas as operações sejam sincronizadas e funcionem sem problemas. Este nível de controle permite que os fabricantes ajustem a máquina para diferentes produtos, garantindo consistência e qualidade em lotes.

4. Fluxo de trabalho eficiente

O design da máquina suporta um fluxo de trabalho contínuo, onde as bolsas se movem perfeitamente de uma etapa do processo para a próxima. Isso reduz gargalos e tempo de inatividade, aumentando ainda mais a eficiência da linha de produção. https://youtu.be/LvyM3Bd83m8

Avaliações

Ainda não há comentários.