Nossas vantagens:

◭ Nossa própria fábrica: Nossa fábrica tem 7000 metros quadrados, mais do que 100 trabalhadores, e 6 Linhas de produção de máquinas, incluindo fabricação de máquinas, polimento, e teste.

◭ Máquinas personalizadas: Nossos principais produtos incluem máquinas emulsificantes de vácuo fixas, homogeneizadores móveis, Todos os tipos de chaleiras agitadoras de reação.

◭ Produtos aplicáveis: Eles são adequados para fazer creme, loção, produtos líquidos, incluindo creme para o rosto, pomadas, ketchup, maionese, Jam, sabonete, shampoo etc..

◭ Certificações: CE, GMP, UL e certificados de tecnologia patenteados.

Todas as máquinas são personalizadas para você!

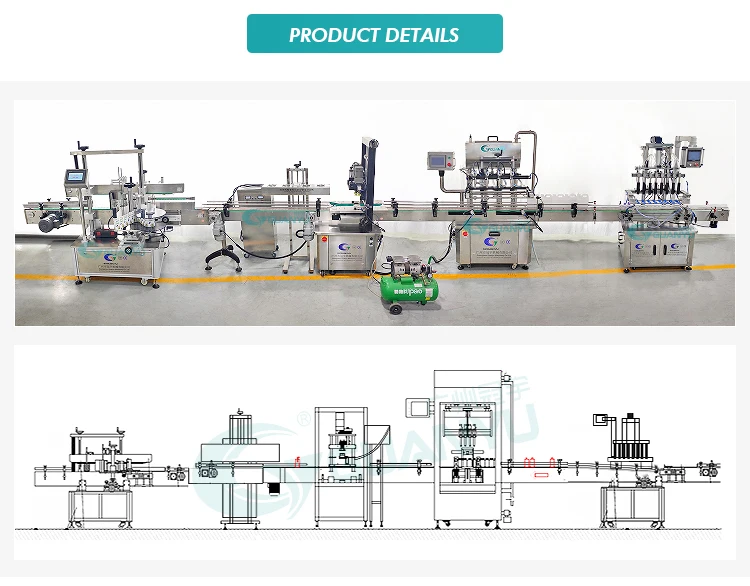

Servir | Todos os equipamentos da linha de produção podem ser customizados de acordo com as necessidades do cliente |

Velocidade máxima de enchimento | preenchendo 200ml, 2000~ 3000 PCs/hora, A velocidade será diferente quando a forma de garrafa e o tamanho do pescoço e o material de enchimento formando e outras propriedades físicas |

Tamanho aplicável do diâmetro da garrafa | 30-300(Mm) |

Tamanho de altura da garrafa aplicável | 30-400(Mm) |

Dose de preenchimento | 500 ~ 5000 ml (Personalizável) |

Precisão de preenchimento | ± 1% |

Tensão | 110V ~ 680V, pode ser personalizado |

Coloque a garrafa | Decodificador de garrafas com liberação automática de garrafas |

Pressão de trabalho | 0.4 – 0.6MPA |

Controle do programa | Interface de homem-máquina da tela de toque PLC+ |

Velocidade de limite | 2000-3000 garrafas/hora |

Caminho da capa inferior | Placa manual ou vibratória |

Selado | Selo de folha de alumínio pode ser adicionado se necessário |

Rotulagem | Face única/dupla face |

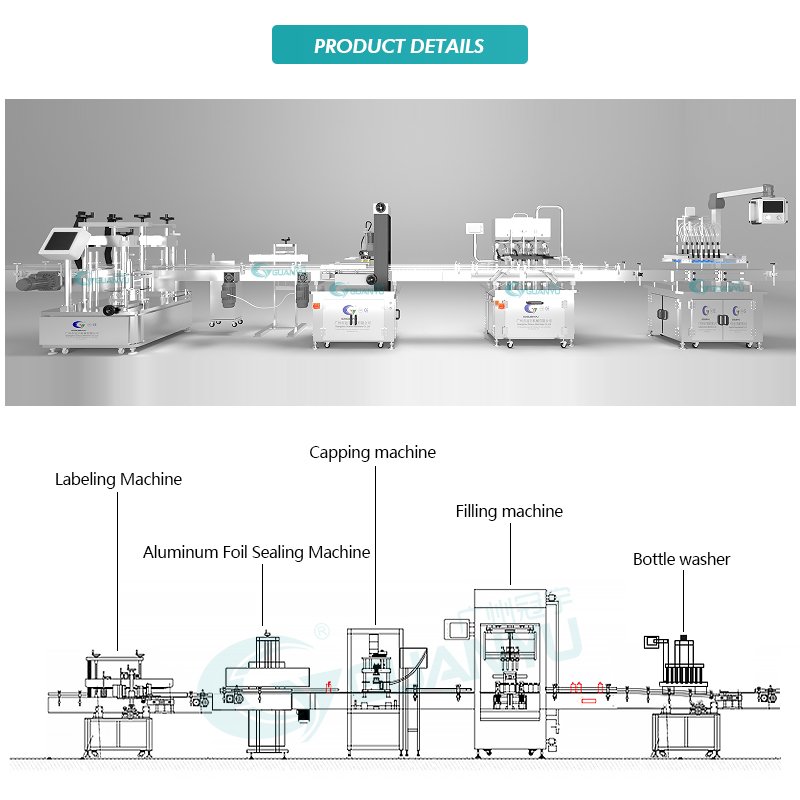

Principais características (Máquina de remoção de poeira de íons negativos):

1. Usando filtragem dupla precisa, a geração de íons eletrostáticos garante que nenhuma partícula de poeira permaneça na garrafa.

2. Armazene automaticamente partículas de poeira para garantir o ar da sala limpa e a saúde do operador.

3. Você pode definir o tempo de limpeza de acordo com suas necessidades;

4. Usar duplo (soprar / inspirar) enxaguatório bucal para remover a poeira da garrafa;

5. Use um filtro de precisão (0.2um) para garantir a limpeza da fonte de ar;

6. É adequado para operações de linha de montagem, e pode ser combinado com várias linhas de montagem, com alta eficiência

7. Esta máquina pode ser usada em fábricas de bebidas, fábricas de alimentos, fábricas químicas, fábricas de cosméticos, fábricas farmacêuticas e outras empresas.

Recursos principais (Máquina de enchimento):

1. O equipamento tem forte compatibilidade, e pode ajustar rapidamente e substituir garrafas de diferentes formas e especificações sem substituir peças, que podem atender aos requisitos de produção de várias variedades e especificações

2. Controle do PLC ,Operação da garrafa de toque ,operação simples e conveniente.

3. O uso de componentes elétricos da marca internacional da Famouse, desempenho e estabilidade.

4. O usuário pode ajustar o intervalo de enchimento, Os materiais não são suficientes na tremonha, o computador dará o sinal da bomba de alimentação para

adicionar material por sensor de nível. Quando o material está cheio, A bomba vai parar automaticamente.

5. O corpo da máquina é feito por 304 aço inoxidável, fácil de limpar, A máquina é total conformidade com os requisitos de GMP.

6. Bomba peristáltica ou sistema de enchimento de bomba de pistão, medição de precisão, manipulação conveniente.

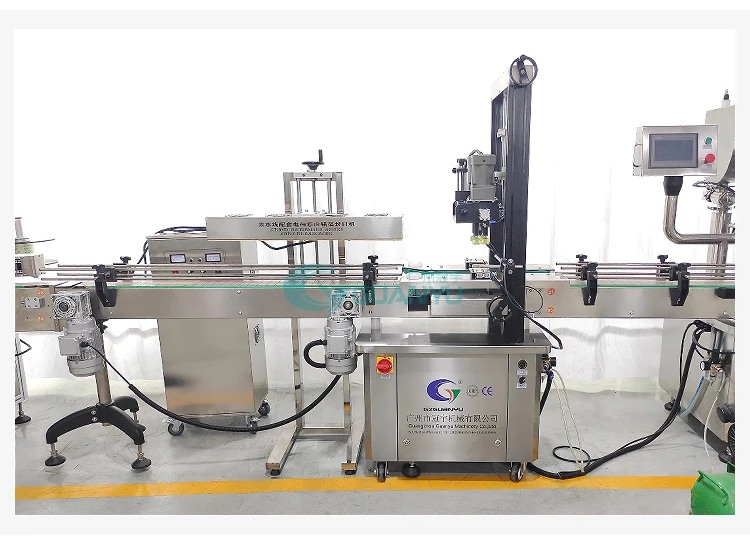

Recursos principais (Máquina de tampa):

1. O elevador de tampas e o alimentador vibratório podem ser selecionados de acordo com o formato da tampa e o tipo de tampa

2. Velocidade de limite rápida, ajustável de 0-45 garrafas/min

3. Garrafas e tampas de diferentes tamanhos podem compartilhar uma máquina ajustando ou trocando alguns acessórios

4. O corpo do tanque do equipamento não gira quando a tampa é rosqueada, o que evita o deslocamento, espalhamento e possíveis danos aos produtos contidos no tanque.

5. que solicitou tampa diferente em materiais diferentes e especificações diferentes.

6. que usam faca de nivelamento tipo 3 rolos ,é fácil regular a pressão.

7. que solicitou tampa de metal ,tampa do tipo parafuso , Pilfer-ProperCap, Cap de compressão, etc ...

Principais características (Rotuladora):

1. Melhore a eficiência da produção, 20-60 peças/min

2. Toda a máquina é feita de aço inoxidável S304 e liga de alumínio de alta qualidade, que atende aos requisitos de produção do GMP

3. Controlado pela interface homem-máquina PLC, dados podem ser salvos, e os dados podem ser chamados diretamente ao trocar a garrafa

4. Esta máquina possui o mecanismo de guiamento de garrafas, divisão de garrafas, rotulagem, nivelamento de rodas, contando e assim por diante.

5. Ampla gama de aplicações, posição de rotulagem, altura e ângulo podem ser ajustados.

6. Pode ser conectado à correia transportadora para ser utilizada na linha de produção

UM:Sim, somos uma fábrica com mais do que 23 Experiência de fabricação de anos. Um está na província de Jiangsu,Outro está em Guangzhou ao lado do nosso escritório.Q:Eu sou novo em nossa indústria,Mas estou planejando para configurar uma fábrica,O que posso fazer?

UM:Vamos projetar a proposta mais adequada com base em suas situações reais como a produção diária,fórmula de matéria-prima, layout de fábrica,etc. também gostaríamos de introduzir alguns excelentes fornecedores de matérias-primas,garrafas, rótulos,etc se necessário.,engenheiro será enviado para instalação de campos,treinamento e comissionamento.

Q:Quanto tempo dura sua garantia?Após a garantia,e se encontrarmos problemas com a máquina?

UM:Nossa garantia é um ano. Após a garantia, ainda oferecemos serviço pós-venda vitalício,sempre que precisar estamos lá para ajudar. Se o problema for facilmente resolver o vídeo de Asolution para você. Se o vídeo não funcionar, enviaremos engenheiro para sua fábrica.

Q:Como você pode controlar a qualidade antes da entrega?

UM:Primeiro,Nossos provedores de peças de componentes/sobressalentes testam seus produtos antes que eles ofereçam compensadores para nós.,nossa equipe de controle de qualidade testará o desempenho das máquinas ou a velocidade de funcionamento antes do envio. Gostaríamos de convidá-lo a vir à nossa fábrica para verificar você mesmo as máquinas. Se sua agenda estiver ocupada. faremos um vídeo para gravar o procedimento de teste e enviaremos o vídeo para você.

Q:Suas máquinas são difíceis de operar? Como você nos ensina a usar a máquina?

UM:Nossas máquinas têm um design de operação de estilo tolo,muito fácil de operar. Além do mais,Antes da entrega, gravaremos o vídeo de instrução para introduzir o MachinesFunctions e ensiná -lo a usá -las. Se os engenheiros necessários estiverem disponíveis para vir à sua fábrica para ajudar a instalar máquinas Machinestest e ensinar sua equipe a usar as máquinas.

Q:Posso ir à sua fábrica para observar o funcionamento da máquina?

UM:Sim, os clientes são muito bem vindos para visitar nossa fábrica.

Q:Você pode fazer a máquina de acordo com o pedido do comprador?

UM:Sim,OEM é aceitável. A maioria de nossas máquinas é um design personalizado com base nos requisitos ou situação do cliente.

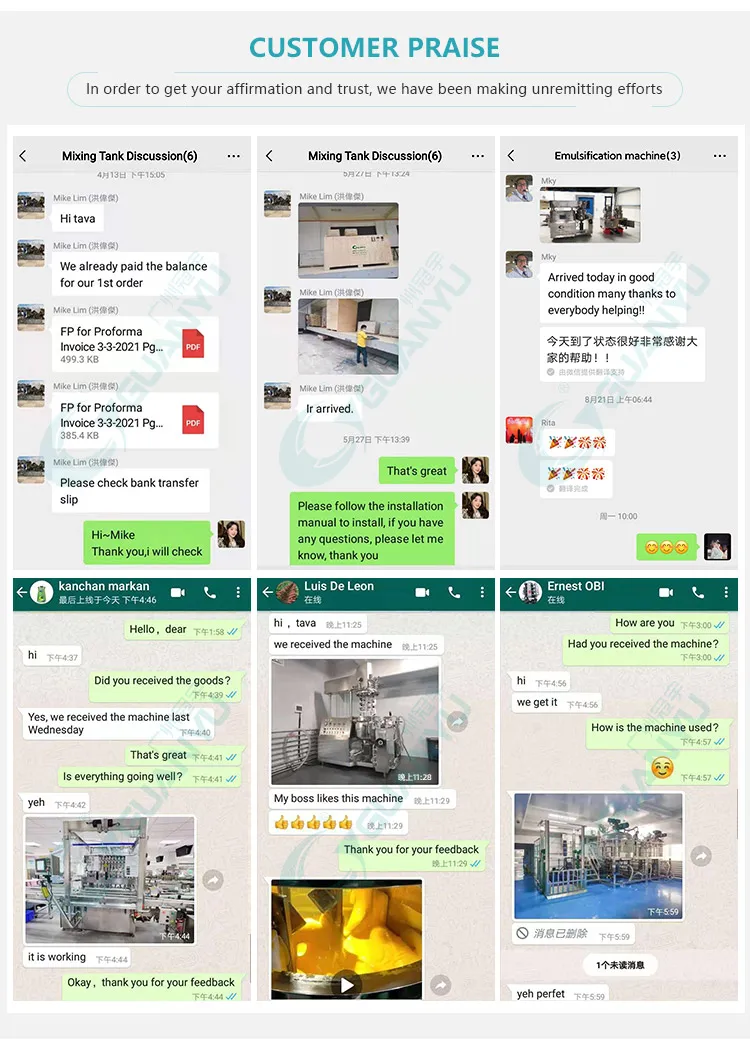

Avaliações

Ainda não há comentários.