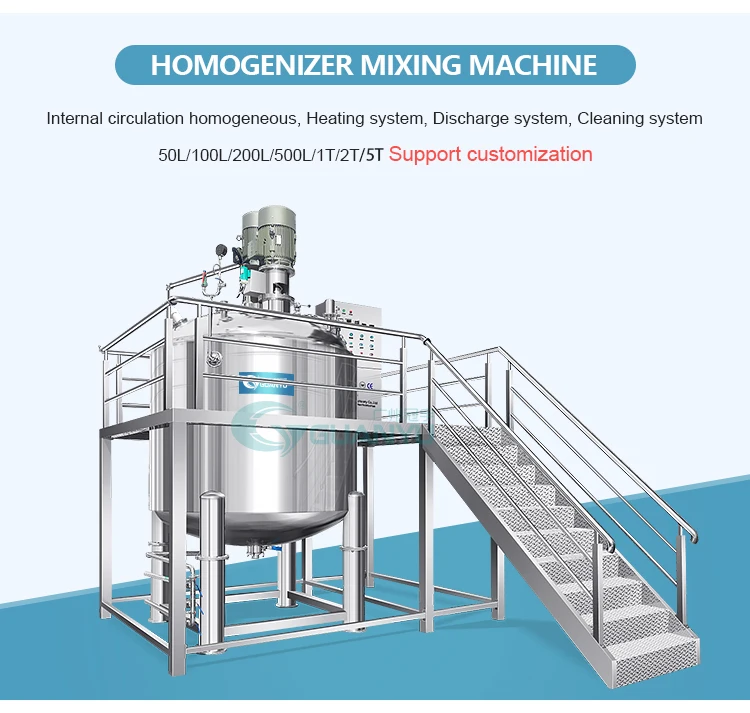

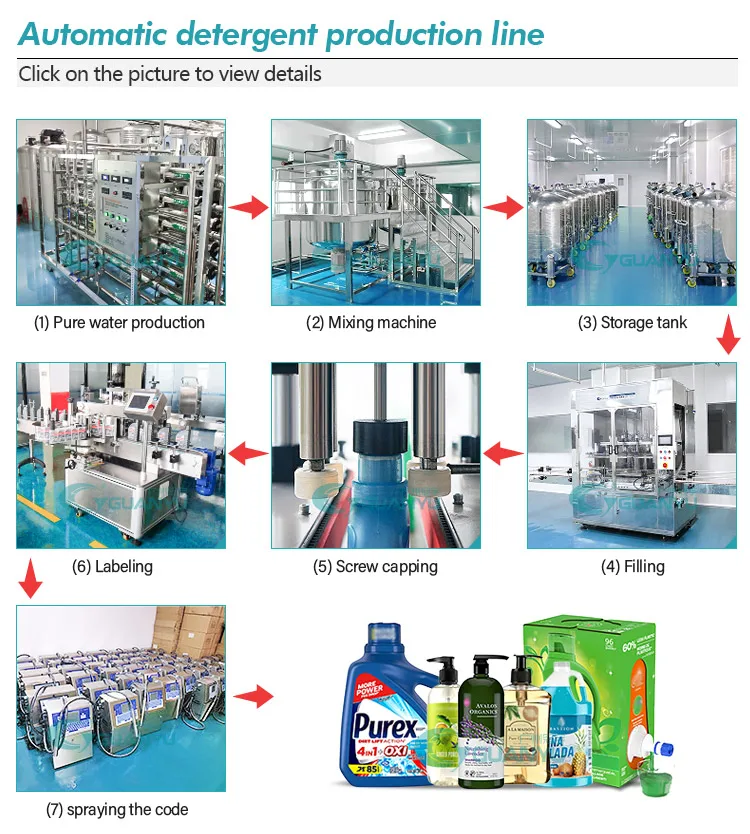

5000L Liquid Mixing Tank Reactor Emulsifier Mixer Homogenizing Emulsifiying Machine Cosmetic Making Gel Production Line

Descrição dos produtos

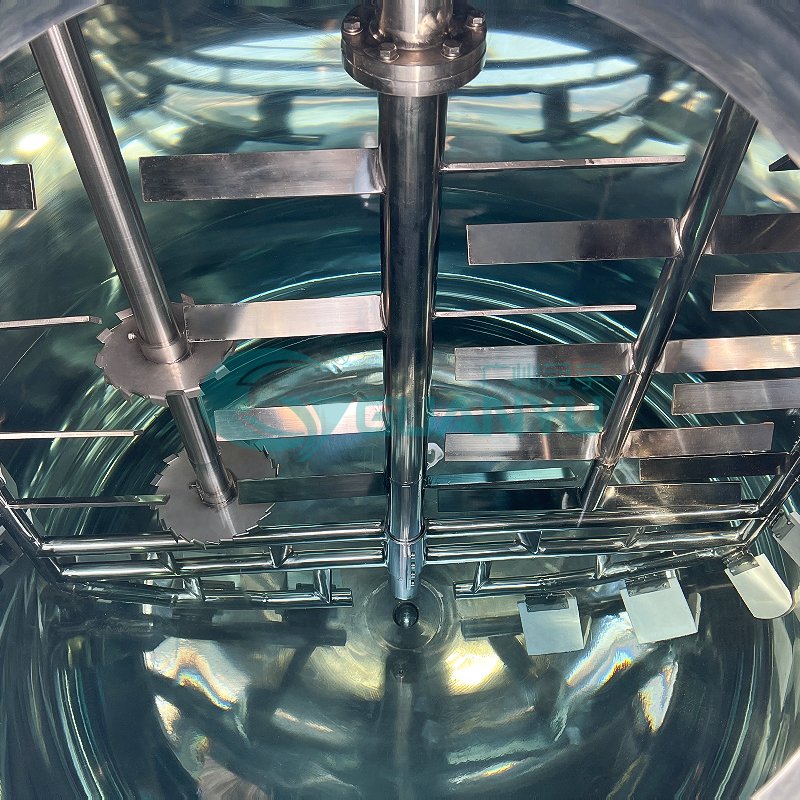

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products ofdifferent processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindissoluble materials such as AES , AESA , LSA , etc.. during the liquid detergent production process so as to save energy consumpion and shorten production period.

◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

Modelo | Volume(eu) | Blending power(kw) | Blending rotation speed(r/min) | Homogenizing power(kw) | Homogenizing rotation speed(r/min) | Método de aquecimento |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Steam heating Or Electric heating |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

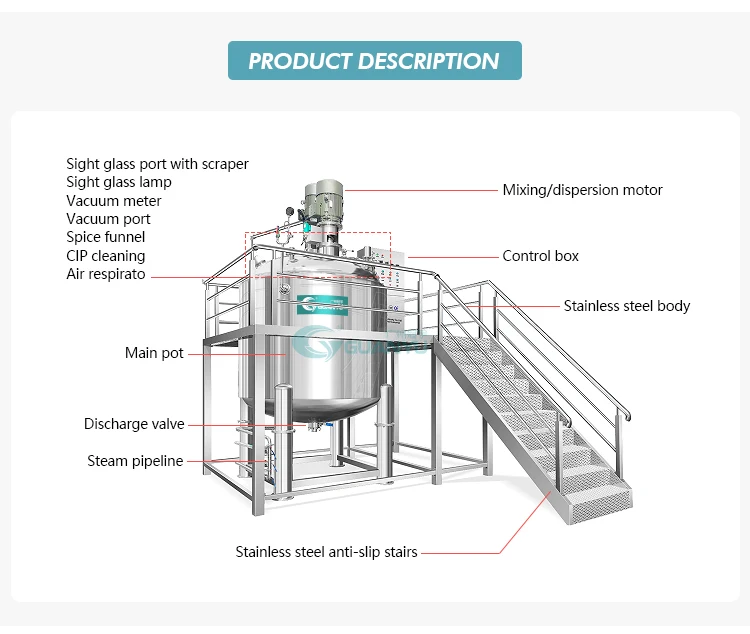

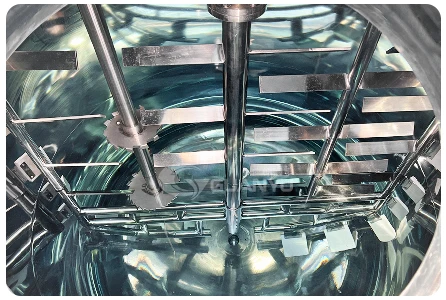

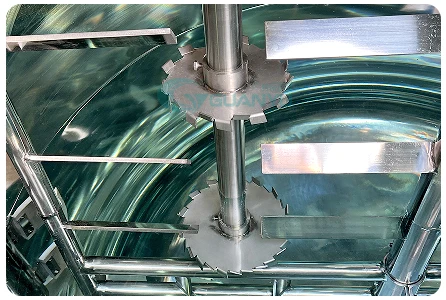

Mixing paddle

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

Dispersed

The upper and lower serrations of the dispersion disc can shear, impact, smash and disperse materials such as paint, dry powder and solid-liquid at high speed, so as to achieve rapid mixing, dissolution, dispersion and refinement

Sealing design

Sealed aseptic design, equipped with feed filter, drain valve, mirror light, mirror mouth, essence hopper, CIP cleaning, air

respirator, using Siemens, ABB and other motors

respirator, using Siemens, ABB and other motors

Heating

Electric heating or steam heating can be selected, and the material is heated through the interlayer to achieve the ideal

stirring and emulsification state.

stirring and emulsification state.

Console

The control box includes settings such as homogeneous shearing, frequency conversion speed regulation mixing,

working timing, vacuum extraction, interlayer heating, etc..

(PLC control is optional)

working timing, vacuum extraction, interlayer heating, etc..

(PLC control is optional)

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

Avaliações

Ainda não há comentários.