1000L Vacuum homogeneizando jaqueta dupla aço inoxidável

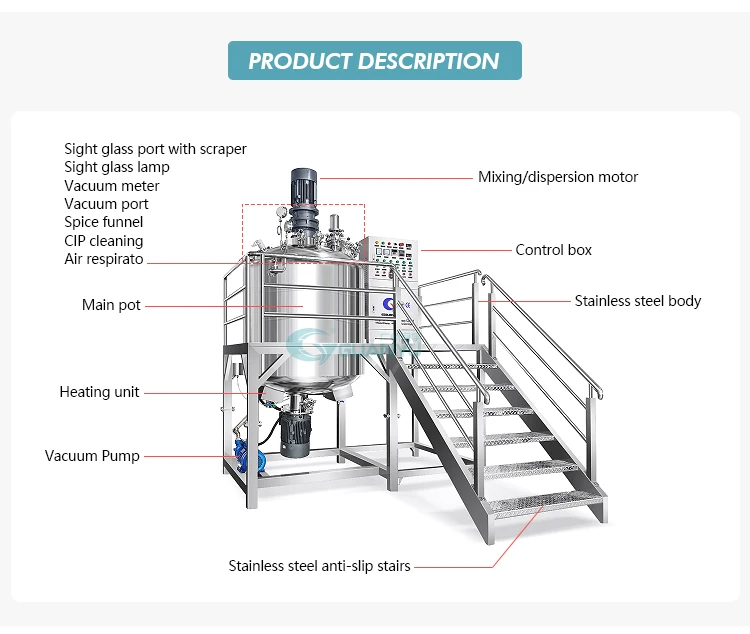

Descrição dos produtos

Modelo | Volume(eu) | Poder de mistura(KW) | Mistura de velocidade de rotação(r/min) | Poder homogeneizador(KW) | Velocidade de rotação homogeneizada(r/min) | Método de aquecimento |

Gym-200 | 200 | 1.5 | 0~ 63 | 4.0 | 0~ 3200 | Aquecimento a vapor ou aquecimento elétrico |

GYM-500 | 500 | 3.0 | 0~ 63 | 7.5 | 0~ 3200 | |

Ginásio-1000 | 1000 | 4.0 | 0~ 63 | 11 | 0~ 3200 | |

GYM-1500 | 1500 | 5.5 | 0~ 63 | 11-15 | 0~ 3200 | |

GYM-2000 | 2000 | 7.5 | 0~ 63 | 15-18.5 | 0~ 3200 | |

Gym-3000 | 3000 | 7.5-11 | 0~ 63 | 18.5-22 | 0~ 3200 | |

GYM-5000 | 5000 | 11-15 | 0~ 63 | 18.5-22 | 0~ 3200 |

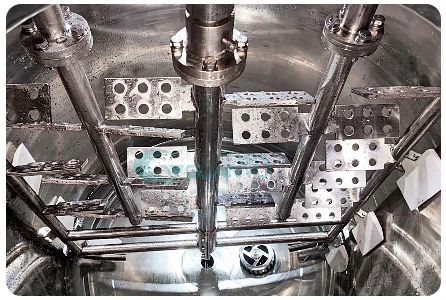

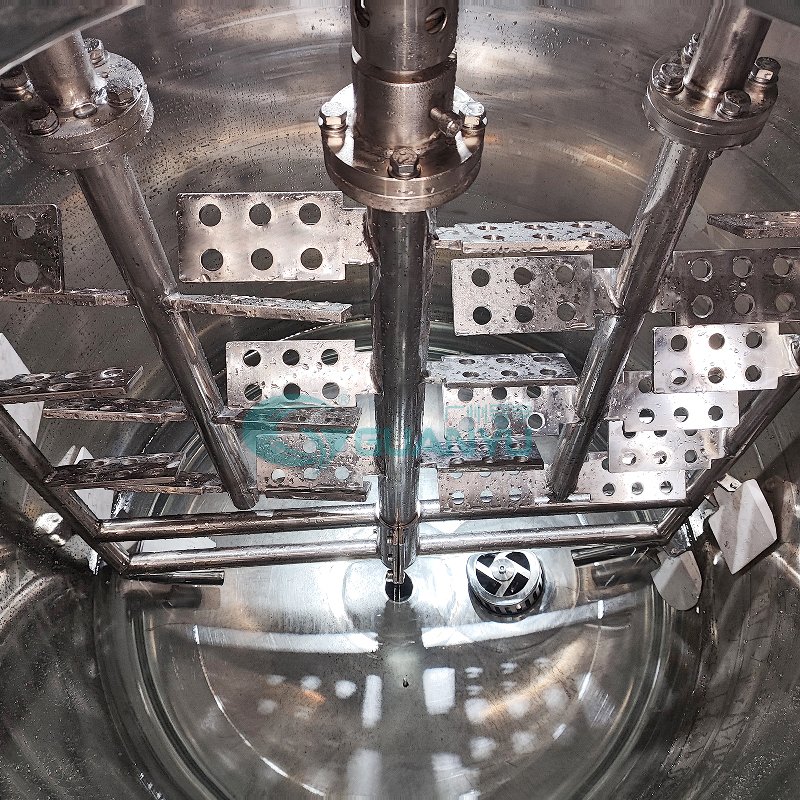

Mistura de remo

A regulação da velocidade de frequência variável é 0-62r/min, para que diferentes materiais possam ser misturados uniformemente. A forma da pá de mistura será projetada de acordo com seus materiais

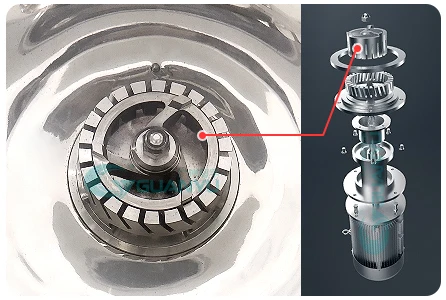

Homogeneizador

Regulação da velocidade de conversão de frequência 0-3200R/min, Materiais de cisalhamento de alta velocidade na cabeça de cisalhamento homogêneo, para que os materiais estejam completamente quebrados e misturados!

Bombas a vácuo

Sob o ambiente a vácuo, O pote de emulsificação pode descarregar espuma quando os materiais são misturados, melhorando assim a qualidade dos materiais a serem tratados. O processo de desarração a vácuo pode garantir a esterilidade dos materiais

Acessórios

Material SS316, grossura 6 mm,Equipado com filtro de sucção, Válvula de drenagem, porta a vácuo, Lâmpada de vidro de mira, Porta de vidro de visão com raspador, funil de especiarias, Limpeza de CIP, Respirador de ar

Console

A caixa de controle inclui configurações como cisalhamento homogêneo, mistura de regulação da velocidade de conversão de frequência,

tempo de trabalho, Extração de vácuo, aquecimento entre camadas, etc..

(O controle do PLC é opcional)

tempo de trabalho, Extração de vácuo, aquecimento entre camadas, etc..

(O controle do PLC é opcional)

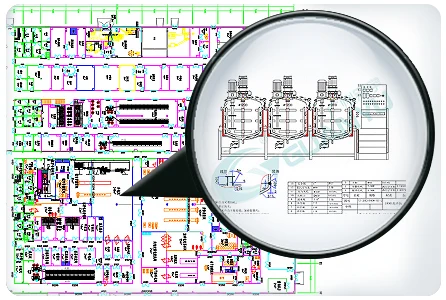

Serviço

Use componentes de marca de renome internacional para garantir a qualidade do equipamento e uma vida útil mais longa

Avaliações

Ainda não há comentários.