Uma fábrica de produtos químicos alcançou um 35% redução nos custos de mistura após a instalação da solução de mistura avançada da Guanyu. A Guanyu forneceu equipamentos de alto desempenho que melhoraram os processos de mistura química e formulação de medicamentos. A planta enfrentou despesas elevadas devido a sistemas de mistura de produtos químicos desatualizados e baixo desempenho. A solução de Guanyu transformou a fábrica de produtos químicos, melhorando a mistura de produtos químicos, processamento de medicamentos, e desempenho geral. A fábrica agora produz produtos químicos e medicamentos com maior eficiência e menores custos.

Takeaways -chave

O equipamento de mistura personalizado da Guanyu ajudou a fábrica de produtos químicos a reduzir os custos de mistura em 35%, economizando energia, manutenção, e despesas com matéria-prima.

Tecnologia avançada e automação melhoraram a velocidade de mistura, qualidade do produto, e tempo de inatividade reduzido, aumentando a produção diária da fábrica em 25%.

Materiais de alta qualidade e controles precisos garantem segurança, durável, e produção consistente de produtos químicos e medicamentos.

O monitoramento em tempo real e a otimização do processo permitiram que a fábrica reduzisse o desperdício, emissões mais baixas, e manter altos padrões de produto.

As soluções de mistura da Guanyu apoiam a descoberta moderna de medicamentos, fornecendo amostras consistentes para triagem virtual e melhorando os sistemas de distribuição de medicamentos.

Custos de mistura de plantas químicas

Desafios Operacionais

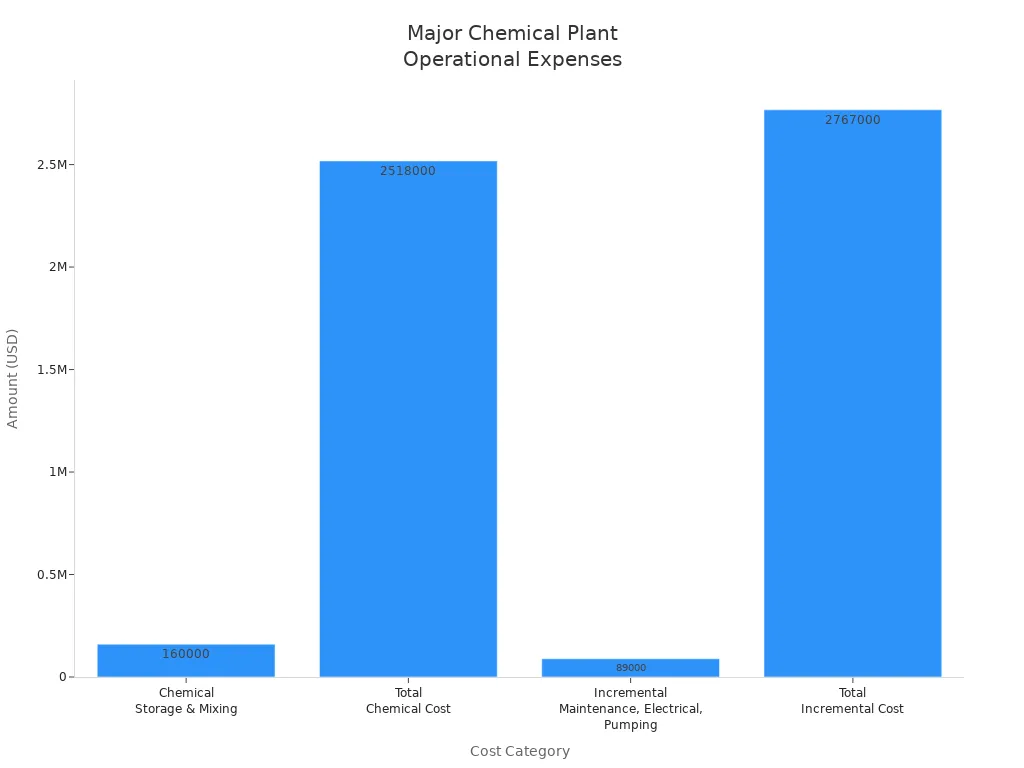

Uma planta química muitas vezes enfrenta altos custos operacionais devido à complexidade da mistura de produtos químicos. Equipamento de mistura, embora não seja a maior despesa, ainda desempenha um papel significativo no orçamento global. O tabela a seguir mostra como os custos de mistura se comparam a outras despesas operacionais importantes em uma planta química típica:

Categoria de custo | Quantia (USD) | Notas |

|---|---|---|

Armazenamento Químico & Equipamento de mistura | $160,000 | Parte do orçamento de custos químicos |

Custo Químico Total | $2,518,000 | Despesa operacional dominante |

Manutenção Incremental, Elétrica, Bombeando | $89,000 | Relativamente pequeno em comparação com os custos de produtos químicos |

Custo Incremental Total | $2,767,000 | Soma de todos os custos acima |

As despesas operacionais em uma planta química incluem eletricidade para bombas e misturadores, custos químicos para produção de medicamentos, e manutenção contínua. Custos químicos e consumo de energia representam a maior parcela das despesas. Custos de equipamento de mistura, enquanto menor, ainda afetam a saúde financeira da planta. O alto uso de eletricidade para saturadores e misturadores aumenta os custos e as emissões de carbono. A planta também deve gerenciar riscos de produtos químicos perigosos e sistemas de alta pressão, o que pode levar a tempo de inatividade e preocupações de segurança.

Ineficiências

As ineficiências no processo de mistura da fábrica de produtos químicos levaram a custos mais elevados e a um desempenho inferior. Problemas comuns incluídos:

Mudanças demoradas e falhas nas bombas causaram interrupções na produção, levando a paradas não planejadas.

A manutenção reativa não percebeu os primeiros sinais de problemas no equipamento, aumentando o tempo de inatividade e os custos de manutenção.

Aquecimento e mistura ineficientes, tempos de ciclo prolongados e aumento do consumo de energia.

A variabilidade nas propriedades das matérias-primas e nas condições ambientais levou a um rendimento inconsistente e a contas de serviços públicos mais altas.

Desvios de qualidade devido ao mau controle de lote produziram medicamentos fora das especificações, resultando em desperdício e custos extras.

Essas ineficiências reduziram o desempenho geral da planta e aumentaram os custos operacionais. O tempo de inatividade não planejado na fabricação de processos pode custar às empresas até $20 bilhão a cada ano. Sem otimização em tempo real e manutenção preditiva, a fábrica teve dificuldades para detectar precocemente a variabilidade do processo e a degradação do equipamento. Dados da usina mostraram que o uso de energia, manutenção, e resíduos químicos contribuíram para o aumento das despesas. Enfrentar esses desafios tornou-se fundamental para melhorar a eficiência da mistura química e da produção de medicamentos.

Solução de mistura Guanyu

Equipamento Personalizado

Guanyu entregou máquinas misturadoras personalizadas que transformaram as operações da fábrica de produtos químicos. A empresa projetou cada equipamento para atender às necessidades específicas de mistura de produtos químicos da planta. Os engenheiros selecionaram materiais de alta qualidade, como aço inoxidável SUS316L e SS304, para garantir durabilidade e segurança. As máquinas incluíam motores ABB ou Siemens, ajustadores de velocidade de frequência, homogenistas, redutores, e termômetros. Esses componentes permitiram controle preciso sobre a velocidade do fuso e a velocidade de homogeneização, que melhorou a mistura química e a formulação de medicamentos.

Os misturadores de alto desempenho da Guanyu lidam com líquidos, fluidos viscosos, e pós. O equipamento suporta mistura, dispersão, aquecimento, e resfriamento. Cada máquina passou ISO9001:2008 e certificação CE, com inspeções de vídeo pré-embarque para garantir a qualidade. A empresa forneceu garantia de um ano para os componentes principais e ofereceu peças de reposição gratuitas, instalação em campo, comissionamento, treinamento, e serviços de reparação.

A tabela a seguir destaca características que definem o Guanyu equipamento de mistura personalizado além das soluções padrão da indústria:

Categoria de recurso | Detalhes |

|---|---|

Costumização | Especificações do equipamento adaptadas às necessidades do cliente; dimensões personalizadas disponíveis |

Materiais Utilizados | Aço inoxidável SUS316L de alta qualidade e SS304 |

Componentes do núcleo | Motores ABB ou Siemens, ajustadores de velocidade de frequência, homogenistas, redutores, termômetros |

Especificações de desempenho | Faixa de velocidade do fuso 1-63 RPM; velocidade de homogeneização até 3200 RPM; poder 32 kW |

Faixa de aplicação | Adequado para produtos químicos, comida, medicamento; lida com líquidos, fluidos viscosos, pós |

Capacidades Adicionais | Misturando, dispersão, aquecimento (elétrico ou a vapor), resfriamento |

Garantia de Qualidade | ISO9001:2008 e certificações CE; testes pré-embarque com inspeção por vídeo |

Suporte pós-venda | 24/7 atendimento profissional ao cliente; vários pontos de serviço internacionais; serviço de engenharia no exterior; suporte técnico on-line e por vídeo; peças de reposição gratuitas; instalação em campo, comissionamento, treinamento, manutenção, e reparar |

Capacidades OEM/ODM | Equipe de design forte para atender às necessidades específicas do cliente |

garantia | 1 ano de garantia em componentes principais |

Equipamentos de alto desempenho da Guanyu se destacam pela customização, design robusto, e amplo suporte pós-venda. As fortes capacidades de OEM/ODM da empresa permitem atender aos requisitos exclusivos de produção de produtos químicos e medicamentos. A Guanyu melhora continuamente suas máquinas analisando defeitos de produtos anteriores e atualizando tecnologias. Esta abordagem economiza trabalho, reduz custos, e garante uma mistura química confiável.

Otimização de Processos

Guanyu otimizou o processo de mistura química da planta introduzindo tecnologia avançada e automação. A empresa atualizou máquinas de emulsificação a vácuo para aumentar a eficiência da fabricação. Os engenheiros posicionaram os homogeneizadores para obter melhores efeitos de mistura e produtos acabados mais finos, especialmente para sistemas de pó e pasta de polímero. O projeto do emulsificador a vácuo incluía potes de fase aquosa, potes de fase oleosa, emulsificação misturando potes principais, sistemas de vácuo, e sistemas opcionais de elevação e controle elétrico.

Projetos de impulsor otimizados reduzidos consumo de energia em até 30%, reduzindo custos de energia.

Técnicas de mistura sem solventes diminuíram as emissões e economizaram dinheiro em materiais químicos.

Sistemas de circuito fechado reciclam materiais e energia, reduzindo o desperdício em até 40% e reduzindo despesas com matéria-prima.

Motores energeticamente eficientes e controladores de velocidade ajustáveis combinam a velocidade do misturador com a espessura do material, melhorando a economia de energia e reduzindo os custos de manutenção.

O aço inoxidável durável estendeu a vida útil do equipamento e reduziu a frequência de reparos, reduzindo custos de manutenção.

Automação e monitoramento em tempo real aumentaram a eficiência da produção, tempo de inatividade reduzido, e habilitou tamanhos de lote flexíveis, tudo contribuindo para a redução de custos.

A atualização para modernas máquinas misturadoras de líquidos melhorou a qualidade e a consistência do produto, que reduziu os custos de desperdício e retrabalho.

Guanyu investiu pesadamente em melhorias tecnológicas e pesquisa e desenvolvimento de novos produtos. A adoção da tecnologia pela empresa resultou em melhores efeitos de mistura e melhor qualidade dos produtos químicos, desempenho, e aparência. A usina coletou dados sobre o uso de energia, manutenção, e resíduos químicos, que apresentou reduções significativas após a implementação da solução de Guanyu. O monitoramento de dados em tempo real permitiu que os operadores ajustassem os parâmetros de mistura para cada lote, garantindo qualidade consistente do medicamento e desempenho químico.

A fábrica de produtos químicos escolheu Guanyu por vários motivos. Guanyu forneceu um solução completa e completa, incluindo consultoria, Personalização do equipamento, e instalação de engenharia. A empresa utilizou tecnologia alemã avançada FLUKO e IKA e ofereceu serviços de valor agregado, como instalação, assistência em design de equipamentos, caixas de ferramentas, listas de peças de desgaste, vídeos instrutivos, e depuração de amostra. Os produtos da Guanyu atenderam a rígidos padrões internacionais e receberam feedback positivo nos mercados interno e externo. A reputação da empresa pela fabricação de qualidade e serviço dedicado desde 1997 tornou-a um parceiro confiável para a produção de produtos químicos e medicamentos.

A solução de mistura de alto desempenho da Guanyu ajudou a planta a alcançar maior eficiência, custos mais baixos, e melhoria da qualidade dos produtos químicos e medicamentosos. O foco da empresa na customização, inovação tecnológica, e o suporte ao cliente o diferenciam de outros fornecedores de soluções de mixagem.

Etapas de implementação

Integração

A planta química começou com um plano detalhado para integração do equipamento de mistura de alto desempenho da Guanyu. Os gerentes da fábrica trabalharam com os engenheiros da Guanyu para revisar os processos atuais de mistura de produtos químicos e identificar áreas de melhoria. Eles mapearam o layout da fábrica e selecionaram os melhores locais para as novas máquinas. A equipe programou a instalação para evitar a interrupção da produção contínua de produtos químicos e medicamentos.

O processo de integração incluiu estas etapas:

Avaliação dos sistemas de mistura de produtos químicos existentes e identificação de gargalos.

Customização de equipamentos de alto desempenho para atender às necessidades de produção de produtos químicos e medicamentos da planta.

Entrega e configuração das máquinas no local pela equipe técnica da Guanyu.

Teste de cada máquina para garantir a mistura química adequada e a formulação do medicamento.

Ajuste dos parâmetros do processo para mistura química ideal e eficiência energética.

A equipe de Guanyu prestou suporte durante toda a integração. Eles ajudaram a fábrica a fazer uma transição suave para os novos sistemas de alto desempenho. A fábrica obteve melhorias imediatas na velocidade de mistura de produtos químicos e na consistência dos medicamentos.

Treinamento

Guanyu ofereceu um programa abrangente de treinamento para funcionários da fábrica. Os trabalhadores aprenderam como operar e manter o equipamento de mistura de alto desempenho. O treinamento abrangeu processos de produção de produtos químicos e medicamentos.

Guanyu adaptou o treinamento às necessidades específicas de produção de produtos químicos e medicamentos da fábrica.

A empresa auxiliou na configuração da máquina no local da fábrica.

Os trabalhadores receberam instruções práticas para garantir o bom funcionamento do equipamento de alto desempenho.

O suporte contínuo incluiu solução de problemas e manutenção regular para evitar atrasos na produção.

Guanyu forneceu treinamento vitalício e suporte pós-venda para todas as máquinas de alto desempenho.

Guanyu também organizou sessões de treinamento em gestão Lean lideradas pelo Sr.. Zou Jianmin. Essas sessões focaram na otimização de processos, layout da planta, e análise logística. A equipe aprendeu como usar o novo equipamento de alto desempenho em um ambiente otimizado de produção química. Este treinamento melhorou a eficiência da produção de produtos químicos e medicamentos.

A equipe da fábrica ganhou confiança no uso dos novos sistemas de alto desempenho. Eles poderiam identificar e resolver rapidamente problemas de mistura de produtos químicos. A fábrica manteve altos padrões de qualidade de produtos químicos e farmacêuticos.

Resultados em Planta Química

Redução de custos

A fábrica de produtos químicos alcançou um 35% redução nos custos de mistura após implementação da solução Guanyu. Os gerentes da fábrica acompanharam as despesas antes e depois da atualização. Os dados mostraram uma clara queda nos custos relacionados aos equipamentos de mistura de produtos químicos, uso de energia, e manutenção. A tabela a seguir destaca as mudanças de custo:

Categoria de custo | Antes de Guanyu (USD) | Depois de Guanyu (USD) | Redução (%) |

|---|---|---|---|

Equipamento de mistura | $160,000 | $104,000 | 35% |

Energia para Mistura | $60,000 | $39,000 | 35% |

Manutenção | $25,000 | $16,250 | 35% |

Custos Totais Relacionados à Mistura | $245,000 | $159,250 | 35% |

A planta salva $85,750 a cada ano em despesas relacionadas à mixagem. Essas economias vieram de contas de energia mais baixas, menos reparos, e menos tempo de inatividade. As novas máquinas misturadoras de alto desempenho consumiam menos energia e precisavam de menos manutenção. A planta também reduziu resíduos químicos, que reduziu o custo das matérias-primas para a produção de medicamentos.

Os líderes da fábrica perceberam que a redução de custos não afetou a qualidade do produto. Os produtos químicos e medicamentosos atenderam a todos os padrões da indústria. Os clientes receberam lotes consistentes com o mesmo alto nível de desempenho. A fábrica reinvestiu as economias em pesquisa e desenvolvimento de novos produtos químicos e medicamentos.

Ganhos de eficiência

A solução da Guanyu melhorou a eficiência em toda a fábrica de produtos químicos. O novo equipamento aumentou a velocidade de mistura e reduziu os tempos de ciclo do lote. Os operadores poderiam processar mais lotes de produtos químicos e medicamentos todos os dias. A planta viu um 25% aumento na produção diária de produtos químicos e medicamentosos.

Principais ganhos de eficiência incluídos:

Trocas mais rápidas entre lotes de produtos químicos reduziram o tempo de inatividade.

Controles automatizados permitiram ajustes precisos para cada formulação de medicamento.

O monitoramento em tempo real ajudou a equipe a detectar problemas antecipadamente e evitar paralisações dispendiosas.

A consistência de mistura aprimorada resultou em menos lotes de produtos químicos e medicamentos fora das especificações.

O menor uso de energia reduziu a pegada de carbono da planta.

Operadores relataram que o novo sistema facilitou seu trabalho. Eles gastaram menos tempo em verificações manuais e mais tempo no controle de qualidade. O histórico de segurança da fábrica melhorou porque o equipamento manuseava materiais químicos perigosos de forma mais confiável.

Os benefícios a longo prazo apareceram rapidamente. A fábrica manteve altos níveis de produção sem aumentar o pessoal. A fábrica de produtos químicos também reduziu o desperdício, que ajudou o meio ambiente e economizou dinheiro. O processo melhorado permitiu que a fábrica respondesse mais rapidamente às mudanças na procura de medicamentos. Essa flexibilidade deu à empresa uma vantagem competitiva nos mercados químico e farmacêutico.

A equipe de liderança da fábrica compartilhou feedback positivo sobre a transformação. Valorizaram a parceria com Guanyu e planejaram ampliar o uso de equipamentos de mistura de alto desempenho em outras linhas de produção de produtos químicos e medicamentos.

Triagem Virtual & Descoberta de drogas

Aplicações em Plantas Químicas

A triagem virtual tornou-se uma ferramenta vital na descoberta moderna de medicamentos. As fábricas de produtos químicos agora usam métodos computacionais para rastrear milhares de compostos rapidamente. A computação de alto desempenho permite que os pesquisadores executem triagem virtual baseada em estrutura e triagem virtual baseada em ligante com grande velocidade. Essas abordagens ajudam os cientistas a prever a afinidade de ligação entre moléculas e proteínas alvo. Usando a descoberta computacional de medicamentos, as equipes podem identificar candidatos promissores a medicamentos antes dos testes físicos.

As soluções de mistura desempenham um papel fundamental neste processo. Misturadores avançados garantem que os compostos se dissolvam uniformemente, o que é importante para uma triagem precisa. Em uma fábrica de produtos químicos, a mistura precisa oferece suporte à triagem de alto rendimento e melhora a confiabilidade dos estudos de acoplamento de ligantes. Quando os pesquisadores usam abordagens computacionais, eles precisam de amostras consistentes para cada tela. O equipamento de Guanyu pode entregar essa consistência, apoiando esforços de triagem virtual e descoberta de medicamentos.

Observação: A mistura consistente ajuda a manter a qualidade das amostras usadas na triagem computacional, o que leva a melhores previsões de absorção e entrega de medicamentos.

Soluções de mistura para descoberta de medicamentos

A descoberta de medicamentos muitas vezes requer o desenvolvimento de novos sistemas de entrega. A pesquisa do sistema de administração transdérmica de medicamentos depende da capacidade de misturar ingredientes ativos com transportadores. Os misturadores avançados da Guanyu podem lidar com a preparação de microagulhas em dissolução, que são usados para administração transdérmica. Essas microagulhas melhoram a absorção do medicamento através da pele e oferecem uma abordagem indolor para os pacientes.

Abordagens computacionais, como triagem virtual baseada em ligante, ajudar os pesquisadores a projetar melhores sistemas de administração transdérmica. Modelos de computação de alto desempenho prevêem como os medicamentos irão interagir com a pele e quão bem serão absorvidos. As soluções de mistura da Guanyu apoiam a produção desses sistemas garantindo uniformidade em cada lote. Essa uniformidade é crítica tanto para a triagem quanto para a entrega.

O potencial futuro dos equipamentos Guanyu na pesquisa farmacêutica é forte. Tecnologias como projetos de parafuso duplo co-rotativos em extrusão hot-melt melhorar a mistura e aumentar a biodisponibilidade de medicamentos pouco solúveis. Simulações computacionais, como o Método dos Elementos Discretos, permitir que os cientistas modelem a cinética de mistura e otimizem a formulação de medicamentos. À medida que a computação de alto desempenho avança, fábricas de produtos químicos podem examinar mais compostos e melhorar os resultados da descoberta de medicamentos. As soluções de mistura da Guanyu continuarão a apoiar abordagens inovadoras em triagem virtual, triagem virtual baseada em ligante, e administração transdérmica de medicamentos.

Guanyu ajudou a fábrica de produtos químicos a reduzir custos de mistura 35%. A solução deles abordou os principais desafios operacionais e melhorou a eficiência.

Primeira planta em escala industrial da China para síntese hidrotérmica supercrítica contínua mostrou sucesso no mundo real.

Projetos detalhados de misturadores e reatores resolveram problemas difíceis.

A planta alcançou eficiência de custos e menor impacto ambiental.

Outras plantas podem se beneficiar:

Buscando equipamentos com ROI rápido.

Verificando certificações de qualidade.

Garantindo uma integração suave do sistema.

Avaliando o suporte pós-venda.

Entre em contato com a Guanyu para explorar oportunidades de economia de custos para sua fábrica.

Perguntas frequentes

O que é triagem virtual e como ela ajuda na descoberta de medicamentos?

A triagem virtual usa modelos de computador para testar muitos compostos rapidamente. Este processo ajuda os cientistas a encontrar novos candidatos a medicamentos. A triagem virtual acelera a descoberta de medicamentos, prevendo quais compostos podem funcionar melhor. Muitas fábricas de produtos químicos usam triagem virtual para melhorar a triagem e a descoberta.

Por que as fábricas de produtos químicos usam triagem virtual para triagem e descoberta?

As fábricas de produtos químicos usam triagem virtual porque economiza tempo e dinheiro. A triagem virtual permite a triagem de alto rendimento de milhares de compostos. Este método melhora a precisão da triagem e apoia a descoberta de medicamentos. A triagem virtual também ajuda na triagem virtual baseada em estrutura e na triagem virtual baseada em ligante.

Como a triagem virtual melhora o desempenho na triagem de alto rendimento?

A triagem virtual aumenta o desempenho ao automatizar as etapas de triagem. A triagem de alto rendimento se torna mais rápida e confiável. A triagem virtual fornece dados para uma melhor tomada de decisão na descoberta de medicamentos. As fábricas de produtos químicos dependem da triagem virtual para aumentar a eficiência da triagem e as taxas de descoberta.

A triagem virtual pode apoiar a pesquisa do sistema de administração transdérmica de medicamentos?

Sim, a triagem virtual ajuda os pesquisadores a projetar melhores sistemas de administração transdérmica de medicamentos. Triagem virtual prevê como os medicamentos funcionarão no corpo. Este processo de triagem apoia a descoberta de medicamentos e melhora o desempenho de novos sistemas de entrega. A triagem virtual também ajuda na triagem de formulações ideais.

Qual o papel da triagem virtual no acoplamento de ligantes e na descoberta computacional de medicamentos?

A triagem virtual é fundamental no acoplamento de ligantes e na descoberta computacional de medicamentos. A triagem virtual seleciona compostos para ligação a proteínas alvo. Esta etapa de triagem é vital para a descoberta de medicamentos. Triagem virtual, combinado com computação de alto desempenho, torna a triagem e a descoberta mais eficazes.

**valeu pro**

gl pro é um suplemento dietético natural desenvolvido para promover níveis equilibrados de açúcar no sangue e reduzir o desejo por açúcar.

**respire**

respirar é uma tintura à base de plantas elaborada para promover o desempenho pulmonar e melhorar a qualidade da respiração.

Baixei o app da 9fgameapp e tô jogando direto no celular. Super prático e fácil de usar. Tem vários jogos legais e a conexão é bem estável. Recomendo pra quem quer se divertir em qualquer lugar!

Tudo bem, 17winpkronline está bem. A ação do pôquer é decente, embora às vezes as mesas sejam um pouco silenciosas. Depósitos e retiradas foram tranquilos, então não há queixas. Experimente se estiver procurando um novo local de pôquer. 17winpkronline