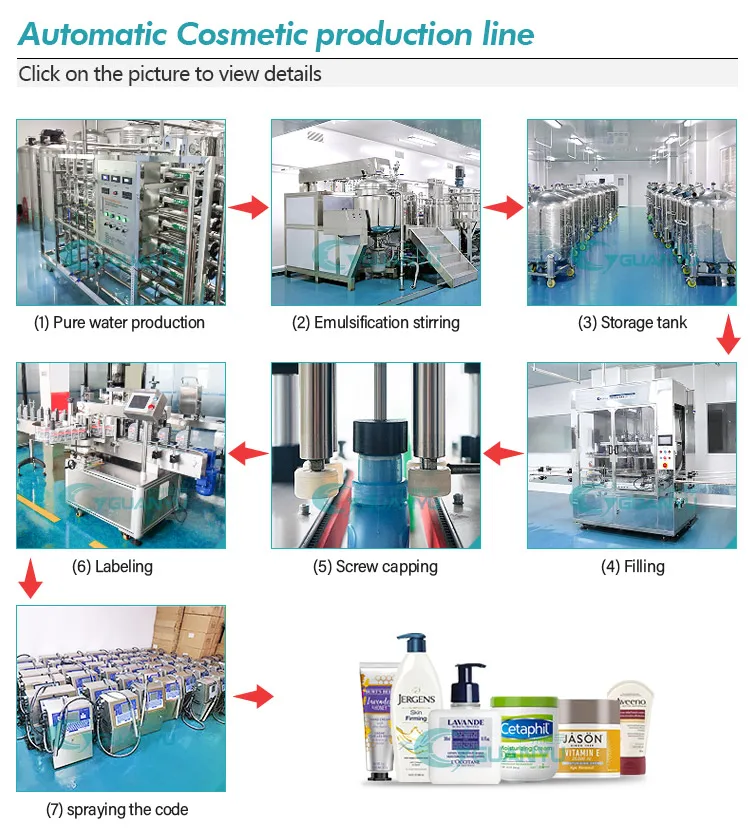

Vacuum Homogenizing Emulsifier Machine Cleanser Lotion Cream Cosmetic Making Machine Liquid Shampoo Soap Blending Equipment

Specification

Specification | Working Volume(L) | Heating Method(optional) | Dimension(L*W*H)(m) | Weight(kg) |

GYE-50 | 50 | Electric heating or steam heating | 2.6*2.4*2 | 650 |

GYE-100 | 100 | 2.8*2.5*2.2 | 850 | |

GYE-200 | 200 | 3*2.8*2.3 | 1100 | |

GYE-500 | 500 | 3.3*3*2.5 | 1500 | |

GYE-1000 | 1000 | 4.2*3.5*3.8 | 2500 |

item | value |

Mixer Type | Homogenizer |

Barrel Volume (L) | 500 |

Material Processed | Chemicals, Food, Cosmetic |

Max. Loading Volume (L) | 500L |

Range of Spindle Speed(r.p.m) | 0r.p.m – 3200r.p.m |

Weight (KG) | 1500KG |

Material | SUS304, SUS316 |

Condition | New |

Product Type | Cosmetic Chemical Food |

Application | Viscous Fluid |

Additional Capabilities | Heating |

Place of Origin | China |

Guangdong | |

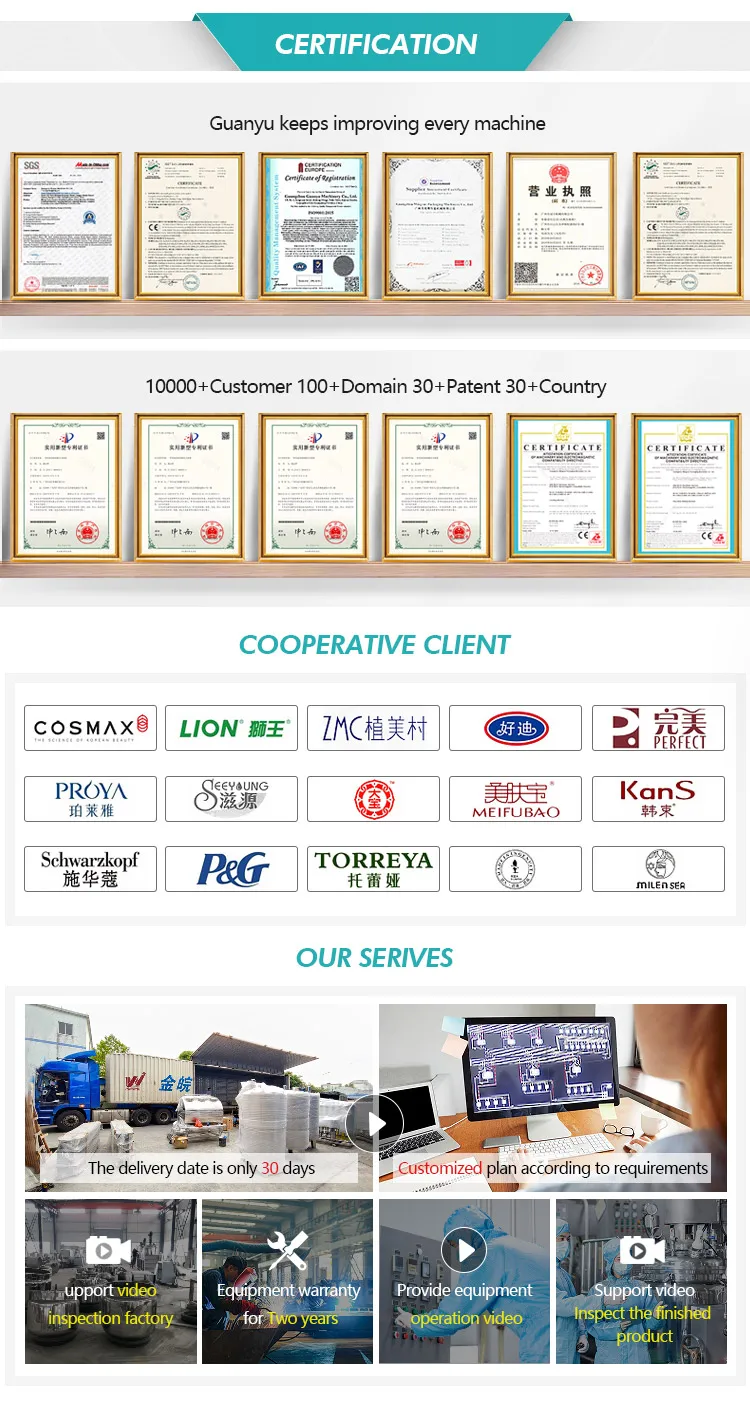

Brand Name | Guanyu |

Power (kW) | 11kW |

Warranty | 1 Year |

Key Selling Points | High Productivity |

Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Cosmetic Factory, Chemical Industry |

Showroom Location | Thailand |

Marketing Type | Ordinary Product |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Warranty of core components | 1 Year |

Core Components | Motor, Pressure vessel, Pump, PLC, Other |

Product name | Homogeneous Emulsifier |

Discharge | Discharge Valve |

Type | Fixed |

Material | Stainless steel 304/316L |

Surface treatment | Mirror polished |

Polish grade | 300MESH |

Layer | Single Layer/Double Layer |

Standard | GMP Standard |

Application scope | Cosmetic Chemical Food |

Capacity | 50~5000L |

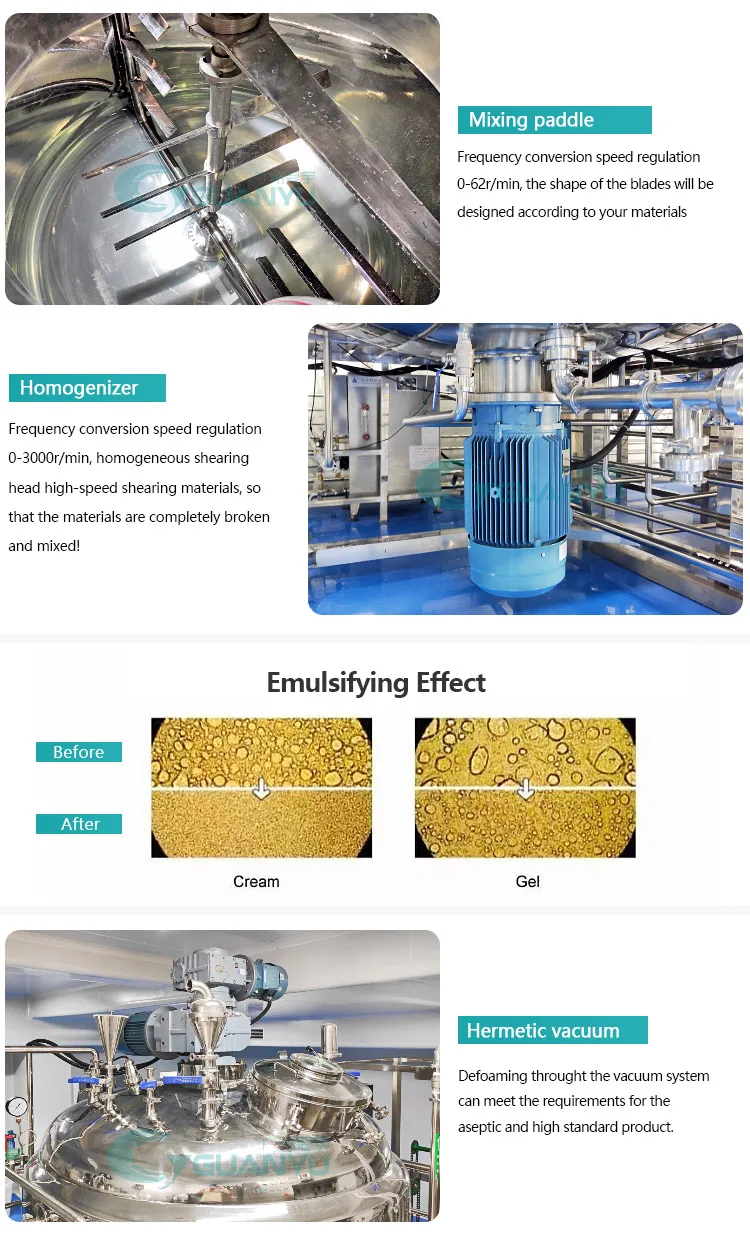

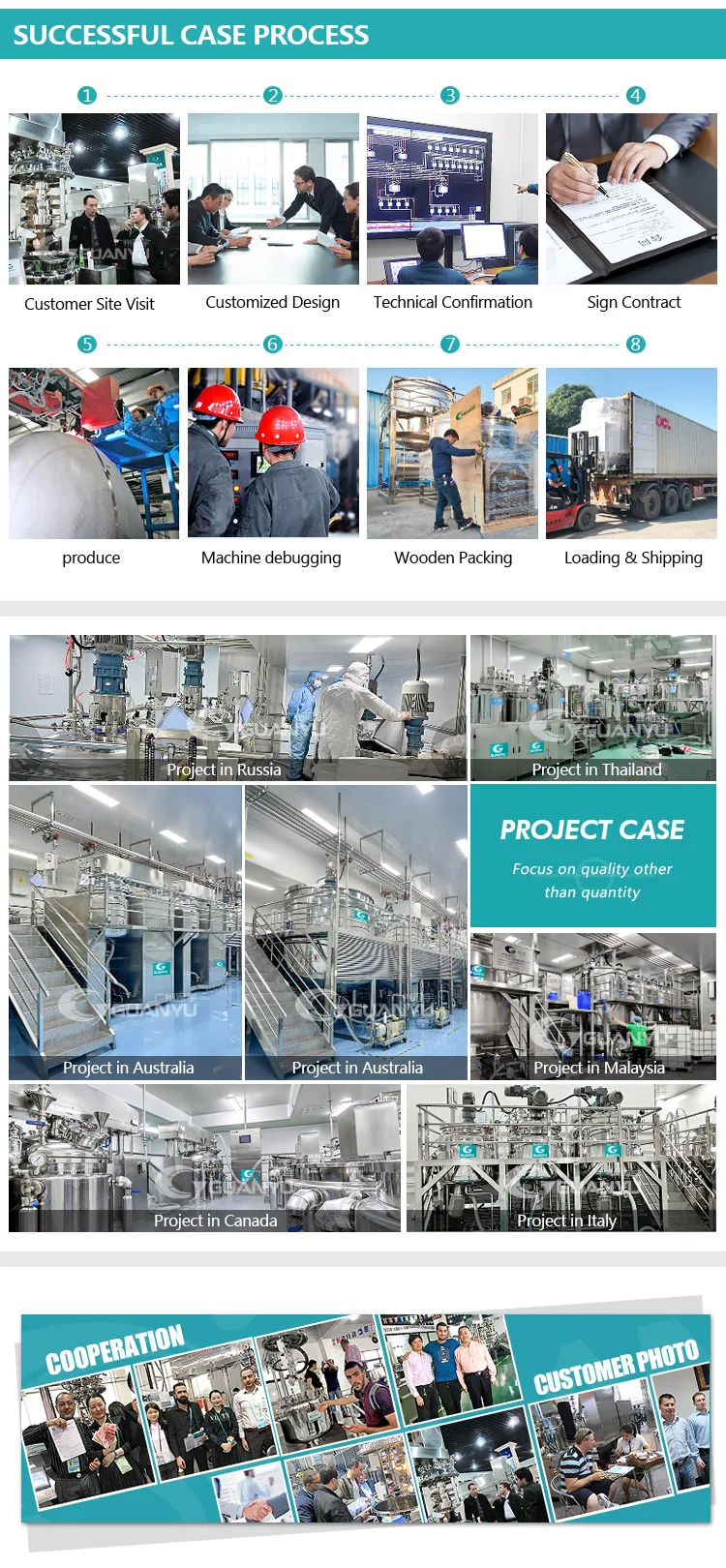

PERFORMANCES AND FEATURES◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindis soluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

FAQ

1.Are you a factory?

A: Yes we are a factory with more than 23 years manufacturing experience.One is in Jiangsu Province, Another is in Guangzhou next to our office.2.I’m new in our industry,but I’m planing to set up a factory what can I do?A:We will design the most suitable proposal based on your actual situation such as the daily production, raw material formula,factory layout etc. Also we would like to introduce some excellent suppliers of raw materials,bottles. labels. etc if needed.After Sales engineer will be send to fields installation training and commissioning.3.How long is your warranty?After warranty what if we encounter problem about the machine?A: Our warranty is one year. After warranty we still offer you lifetime after-sales service,anytime you need we are there to help. If the problem is easily to solve we will shoot a solution video for you. If video doesn’t work out we will send engineer to your factory.4.How can you control the quality before delivery?A: First,our component/spare parts providers test their products before they offer components to us. Besides, our quality control team will test machines performance or running speed before shipment. We would like to invite you come to our factory to verify machines yourself.If your schedule is busy, we will take a video to record the testing procedure and send the video to you.5.Are your machines difficult to operate? How do you teach us using the machine?A: Our machines are fool-style operation design very easy to operate. Besides before delivery we will shoot instruction video to introduce machines functions and to teach you how to use them. If needed engineers are available to come to your factory to help install machines test machines and teach your staff to use the machines.6.Can I come to your factory to observe machine running?A: Yes, customers are warmly welcome to visit our factory.7.Can you make the machine according to buyer’s request?A: Yes, OEM is acceptable. Most of our machines are customized design based on customer’s requirements or situation.

Reviews

There are no reviews yet.