Vacuum Emulsifier Homogenizer Cosmetic Cream Mixer Machine Vessel Ointment Vacuum Toothpaste Paste Emulsifier Making Machine

Products Description

Vacuum Emulsifying Mixer Cream Making Machine Vacuum Homogenizing Tank Composed of pretreating boilers, vacuum emulsifying andblending boiler, vacuum pump, hydraulic liftsystem, dumping system,electric control system and work platform etc. Suitable for production of ointment and cream products in cosmetic and pharmaceutical plants. The emulsifying effect is moreprominent for materials of high base viscosity and high solid content.

Heating method: | Material: | Certificate: | Type: |

Steam or electricity | SUS304 and SS316 | CE | Tilting Type with Lower Homogenizer |

Production Capacity | Usage: | Control Method: | Power |

50L-2T, customized | Produce cream, gel, lotion, shampoo etc | Manual or by touch screen | 380V 3Phase 50Hz(customization) |

Mixing paddle

Frequency conversion speed regulation 0-62r/min, the shape of the blades will be designed according to your materials.

Homogenizer

Frequency conversion speed regulation 0-3000r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Hermetic vacuum

Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product.

Oil-water pot

Pre-treatment System Water phase and oil phase pot to pre-heat and disperse the raw materials, then transfer them to main pot to begin production.

Console

The control panel displays and controls

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

( Optional PLC control )

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

( Optional PLC control )

Electric box

Use internationally renowned brand

components to ensure the quality of the

equipment and longer service life

components to ensure the quality of the

equipment and longer service life

Service

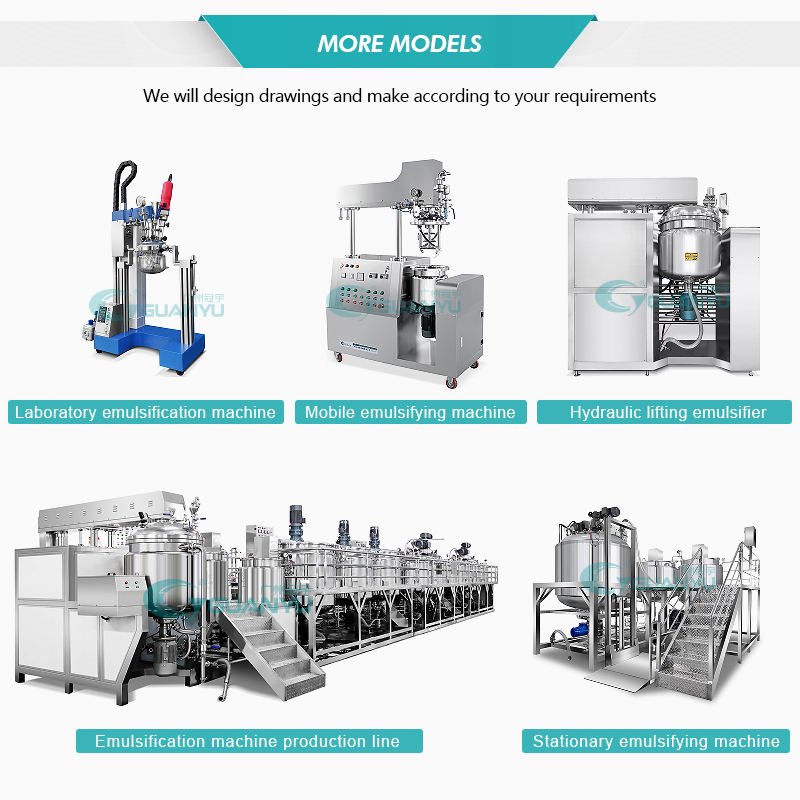

We will design drawings according to your

requirements and provide one-stop solutions.

requirements and provide one-stop solutions.

Product configuration

About Us

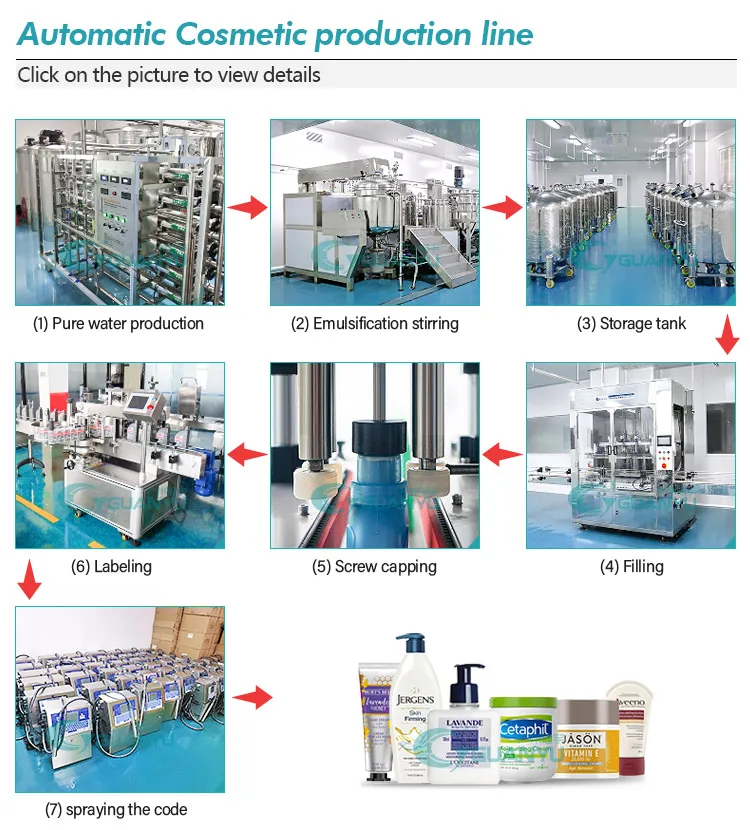

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.