Stainless Steel Reactor Chemical Reaction Mixer Mixing Kettle Liquid Fertilizer Making Machine High Shear Mixing Tank

Product configuration

Model | Volume(L) | Blending power(kw) | Blending rotation speed(r/min) | Homogenizing power(kw) | Homogenizing rotation speed(r/min) | Heating method |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Steam heating Or Electric heating |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products ofdifferent processes according to customer requirements.

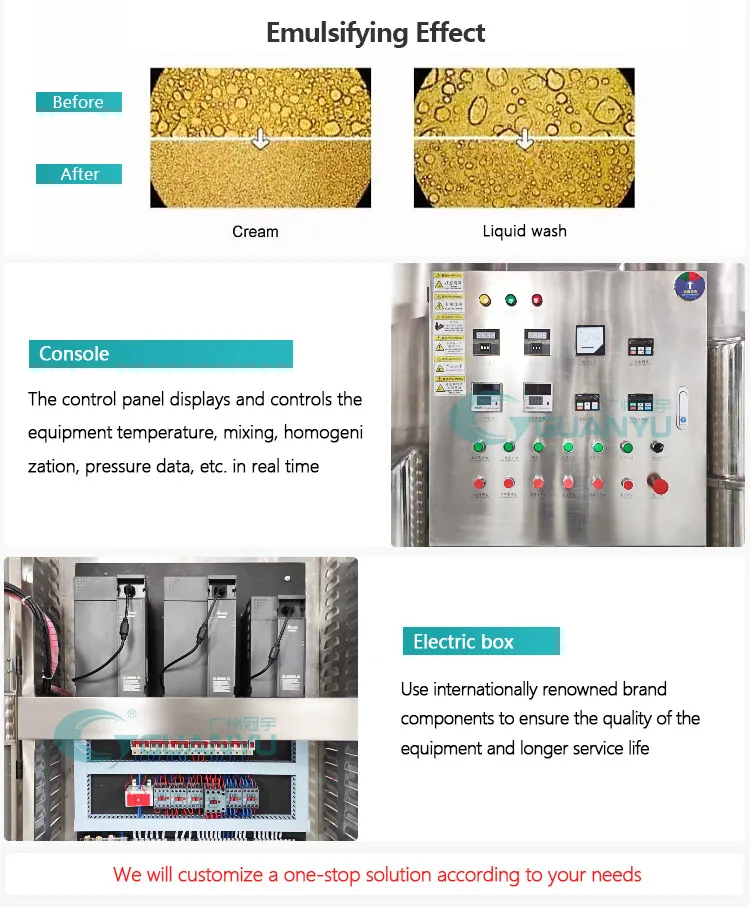

reactor stirred tank◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production p reactor stirred tankrocess so as to save energy consumpion and shorten production period.

reactor stirred tank◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements. reactor stirred tank

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump. reactor stirred tank

Product configuration

Related Products

About Us

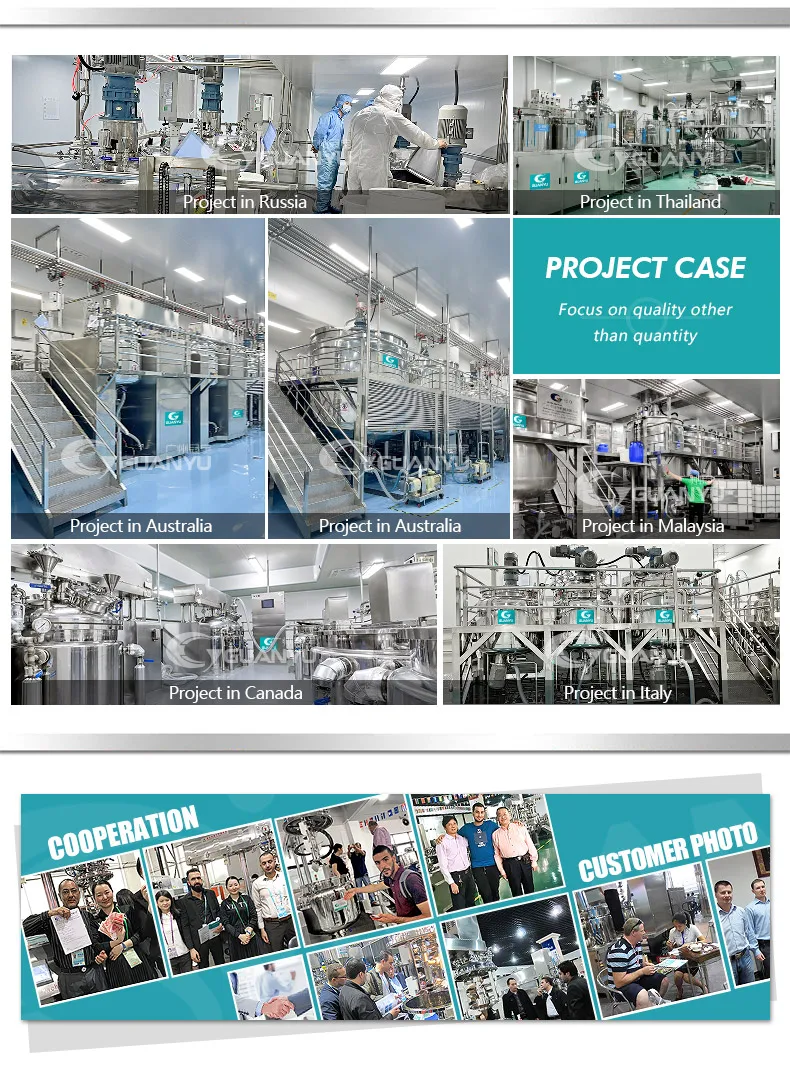

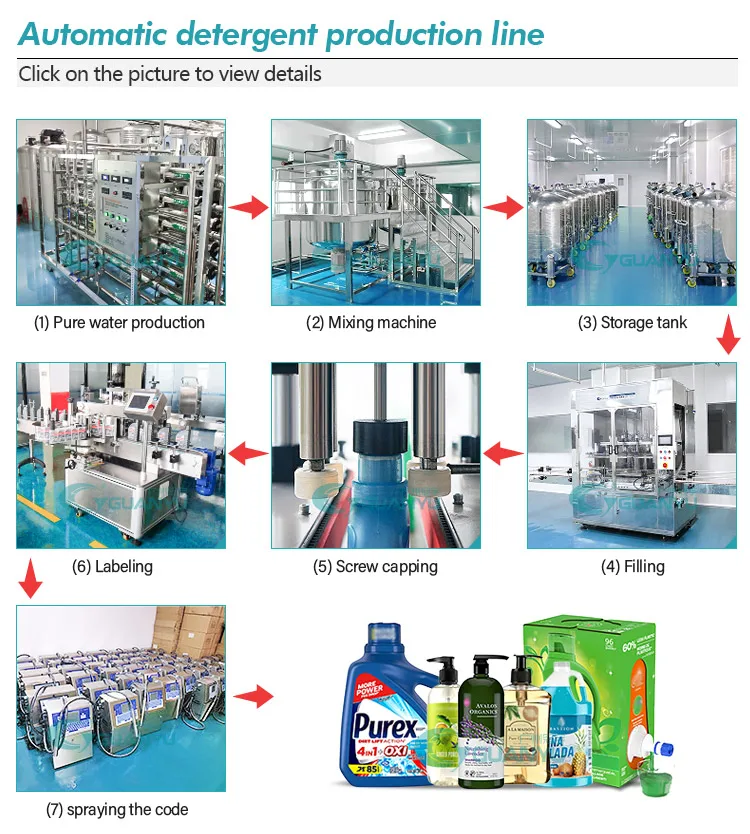

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.