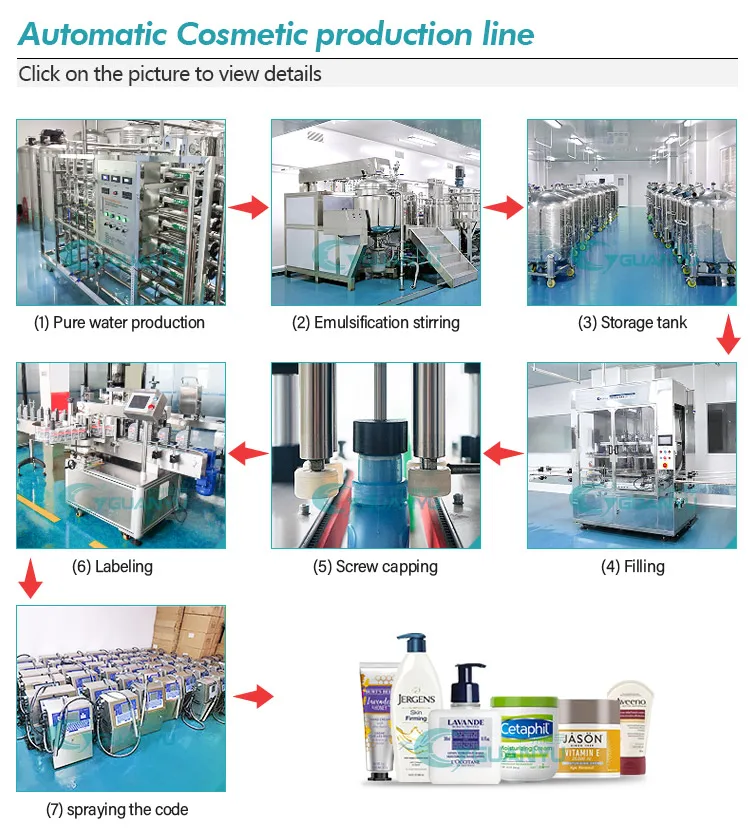

Guanyu 100L Cosmetic Lotion Cream Mixer Blender Homogenizer Ointment Vacuum Emulsifying Emulsifier Cosmetic Cream Making Machine

Products Description

Model | Volume(L) | Blending Power(KW) | Blending Speed(r/min) | Homogenizing Power(KW) | Homogenizing Rotation Speed(r/min) | Heating Method |

GYM-200 | 200 | 1.5 | 0-63 | 4.0 | 0-3200 | Steam Heating Or Electric Heating |

GYM-500 | 500 | 3.0 | 0-63 | 7.5 | 0-3200 | |

GYM-1000 | 1000 | 4.0 | 0-63 | 11 | 0-3200 | |

GYM-1500 | 1500 | 5.5 | 0-63 | 11-15 | 0-3200 | |

GYM-2000 | 2000 | 7.5 | 0-63 | 15-18.5 | 0-3200 | |

GYM-3000 | 3000 | 7.5-11 | 0-63 | 18.5-22 | 0-3200 | |

GYM-5000 | 5000 | 11-15 | 0-63 | 18.5-22 | 0-3200 |

PERFORMANCES AND FEATURES

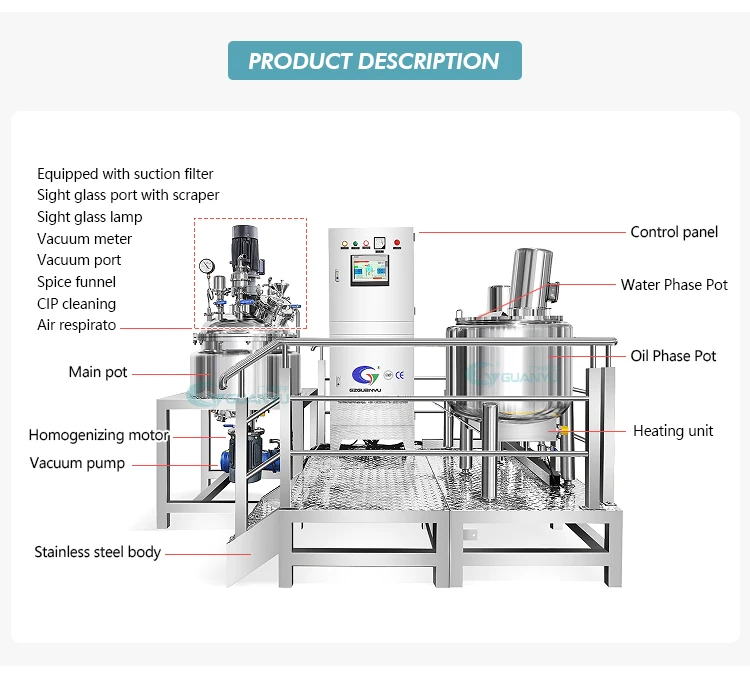

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindis soluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

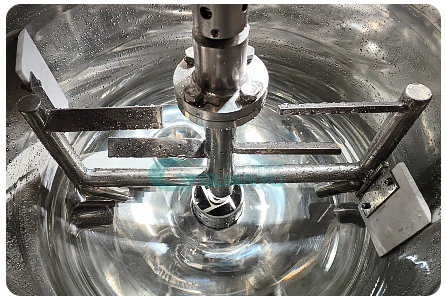

Mixing paddle

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

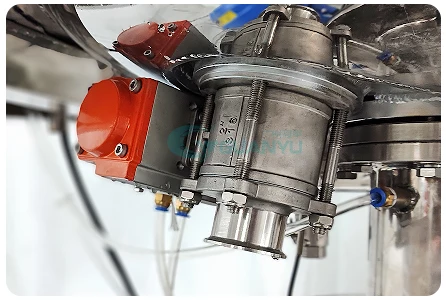

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Accessories

Material SS316, thickness 6 mm,Equipped with suction filter, drain valve, vacuum port, sight glass lamp, sight glass port with scraper, spice funnel, CIP cleaning, Air respirator

Pneumatic valve

Both the feeding port and the discharging port can be equipped with pneumatic valves, and the feeding and discharging can be automatically controlled through

the PLC panel.

the PLC panel.

PLC Console

PLC touch screen control panel, real-time display and control: inlet and outlet valve switch, equipment emperature, stirring/homogenizing speed working time, etc.

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

Reviews

There are no reviews yet.