Guangzhou Guanyu Machinery Co.,Ltd

Custom Making Machine Supplier

Guangzhou Guanyu

Cosmetics / Daily chemical / Pharmaceutical / Food Equipment one-stop solution

Guanyu Machinery Company

Established in 1987

Provide a variety of products of production equipment one-stop solution

With the advanced technology production and inspection equipment and the specialized processes, we have been a professional equipment manufacturer & pharma machine manufacturer and provided kinds of the equipment based on the market requirement.

800+

Technical staff

35+

Years of Experience

10+

Senior Engineer

2+

years warranty and lifelong maintains

Production Solution

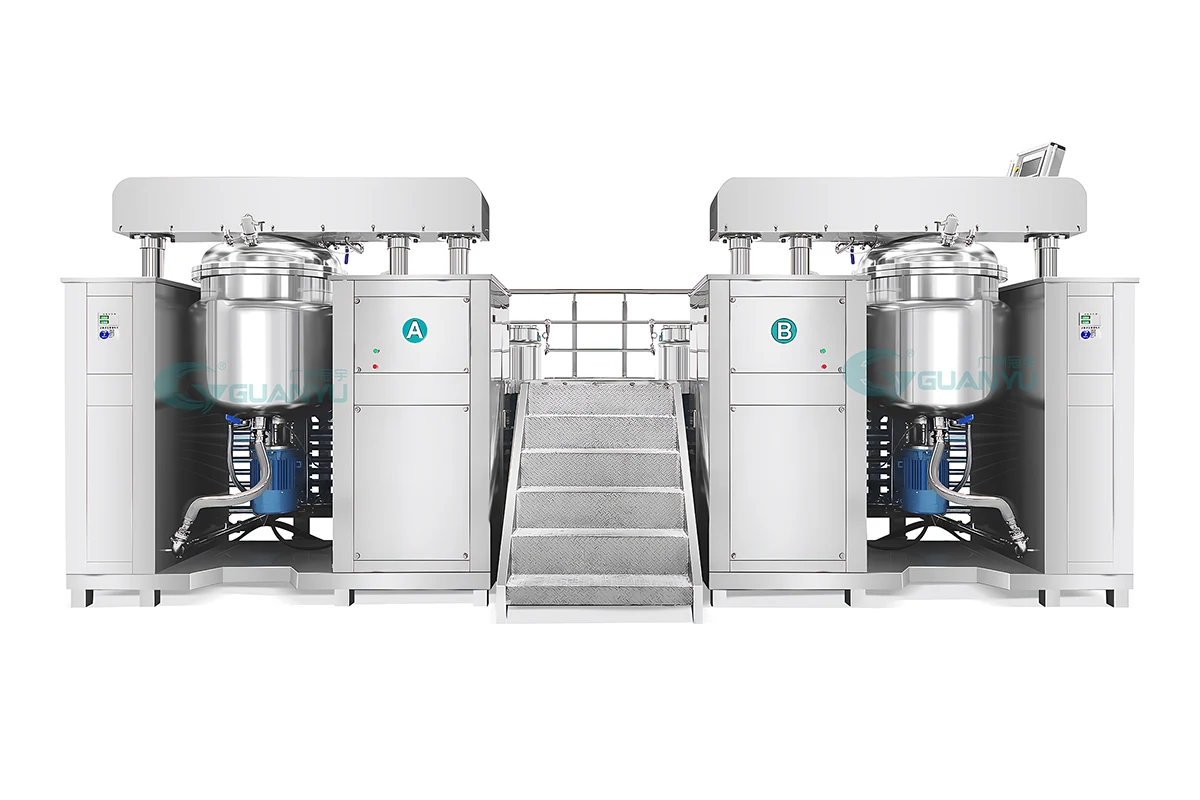

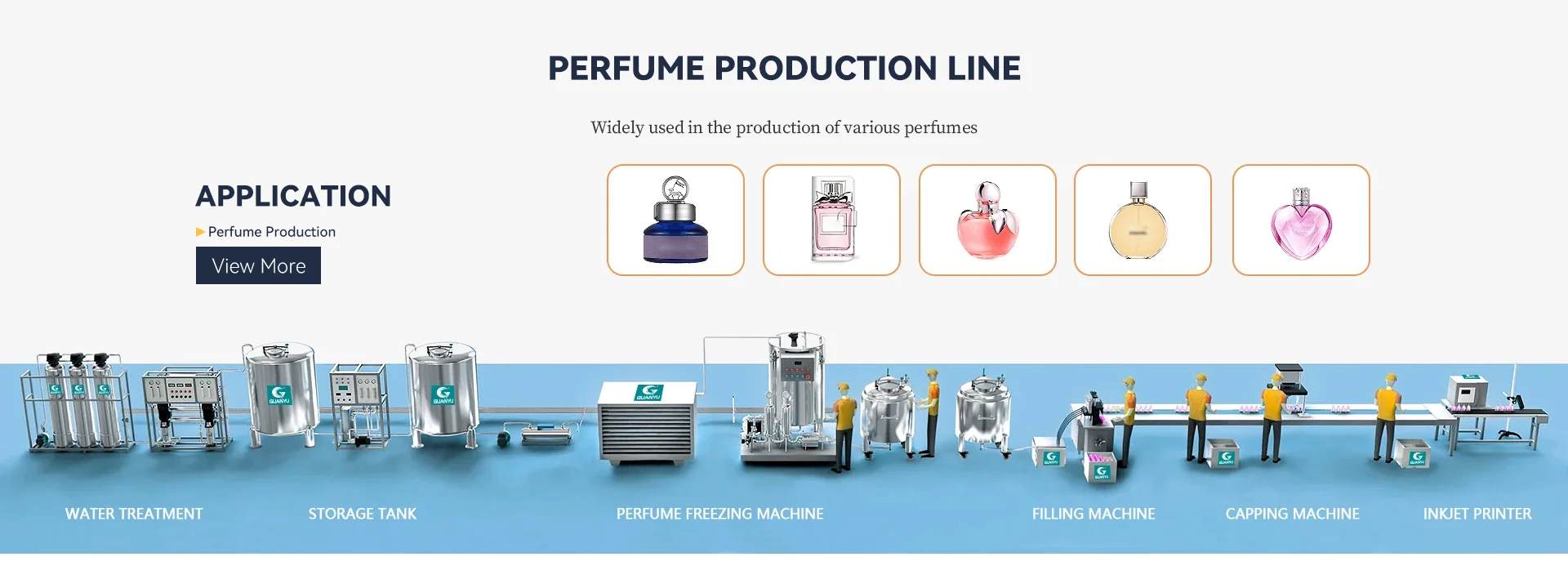

Our company provide one-stop solutions for the production of cosmetics, food, pharmaceuticals, chemicals, and new energy industries. Main products: various reactors, including emulsifier, emulsification tank, mixing tank, mixing pot, mixer, vacuum emulsifier, homogenizer, and supporting bottle washer, dryer, filling machine, and capping machine , labeling machine, inkjet printer, sealing and cutting machine (shrinking machine), cartoning machine and other complete packaging equipment

Why Choose Guanyu

Rich experience in mechanical manufacturing

More than 35+ years of machinery manufacturing experience, strict quality control and thoughtful customer service.

We Follow Best Practices

From raw material production to product packaging, design solutions for each customer

- We can customize the machines according to customers demands;

- we can help customer to handle the whole process of producing daily cosmetic, from raw material, packages, decoration machines etc;

- We have 10 engineers, they can fly to foreign countries to fix and install machines

- We can choose the shipping method according to your needs, and the equipment is guaranteed for 2 years, Lifetime warranty

One-Stop Solution

Quality Services

Installation Qualification

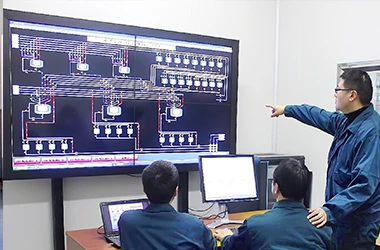

Our commitment to efficient machinery installation takes precedence in our service offerings. The Installation Qualification process is meticulously designed to ensure a rapid and smooth implementation, reducing downtime and getting your operations up and running promptly.

Operation Qualification

Prioritizing operational efficiency, our Operation Qualification measures guarantee not just the confirmation of operations but operational excellence. We focus on ensuring that every machine functions according to specifications promptly, meeting time-sensitive demands with precision.

Performance Qualification

Performance Qualification is not solely about confirming performance; it's about delivering optimal performance within specified timelines. Our PQ standards are geared towards ensuring machinery not only meets but exceeds performance expectations. With a dedicated focus on timely deliveries, we ensure your operations run seamlessly without unnecessary delays.

Design Qualification

At the forefront of our service is Design Qualification, emphasizing swift and precise blueprinting for timely solutions. Every aspect of machinery design is tailored to your needs with a keen focus on efficiency, ensuring the timely creation of design plans and drawings that align seamlessly with your unique requirements.

Customer Evaluation

-Very satisfied with this purchase,the machine is very efficient and energy-saving

-Great service and the machine is perfect.Hope the next crder will be as perfect as the machine.

-The quality of the machine is very good,there is a chance to continue cooperation

Flexible Collaboration

We redefine the manufacturing experience by placing your needs at the forefront. Our emphasis on customization goes beyond standard offerings—our services are designed to create production line equipment that aligns precisely with your requirements. We invite you to actively participate in the entire design process, allowing your insights and preferences to shape the development of the production line.

About Product

Application Fields

About Experience

Cooperation Case

About Founders

CUSTOMIZATION PROCESS

management leadership

Our Team

CEO Executive

Alice Howard

This product demonstrates outstanding machine quality and is accompanied by highly professional sales personnel.

Engineer

Ema Romero

I received it in a wooden box. It looks good. I haven’t started using it yet.

Business manager

Nathan Marshall

We have cooperated with each other many times, and the storage tanks are all purchased here, which is good.

Corporate Culture & Development history

Innovative Excellence

Forged in a legacy of innovation, our company thrives on a culture of excellence, driving sustained growth through unwavering commitment to quality and customer satisfaction.

2010

Guangzhou Guanyu Machinery Co., Ltd. was established, located in Baiyun District, Guangzhou.

2014

ISO9001 quality management system certification.

2016

The company was identified as a high-tech enterprise in Guangdong Province.

2016

The company was identified as a high-tech enterprise in Guangdong Province.

2017

The company further expanded its scale and moved to Panyu District, Guangzhou.

2019

The company was identified as a national high-tech enterprise.

2020

The company launches the first gantry machining center and begins sales.

2021

The company launched the first five-axis linkage machining center and began sales.

Request a Quote

Learn More From

Frequently Asked Questions

Yes we are a factory with more than 35+years manufacturing experience. One is in Jiangsu Province, Another is in Guangzhou next to our office.

We will design the most suitable proposal based on your actual situation, such as the daily production, raw material formula, factory layout, etc. Also we would like to intro-duce some excellent suppliers of raw materials, bottles, labels, etc if needed. After sales, engineer will be send to fields installation, training and commissioning.

Our warranty is 2 year. After warranty we still offer you lifetime after-sales service, anytime you need we are there to help. If the problem is easily to solve, we will shoot asolution video for you. If video doesn’t work out, we will send engineer to your factory.

First, our component/spare parts providers test their products before they offer com-ponents to us. Besides, our quality control team will test machines performance or running speed before shipment. We would like to invite you come to our factory to verify machines yourself. If your schedule is busy, we will take a video to record the testing procedure and send the video to you.

Our machines are fool-style operation design, very easy to operate. Besides, before delivery we will shoot instruction video to introduce machines’ functions And a paper instruction manual

to teach you how to use them. If needed engineers are available to come to your factory to help install machines, test machines and teach your staff to use the machines.

Yes, customers are warmly welcome to visit our factory.

Yes, OEM and ODM is acceptable. Most of our machines are customized design based on cus-tomer’s requirements or situation.