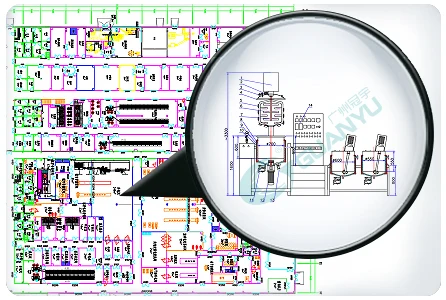

Specification VMH | Working Volume(L) | Heating method(Optional) | Dimension(L x W x H)(m) | Weight(kg) |

150 | 150 | Electric heating or Steam heating | 2.6 x 2.4 x 2 | 650 |

250 | 250 | 2.8 x 2.5 x 2.2 | 850 | |

350 | 350 | 3 x 2.8 x 2.3 | 1100 | |

500 | 500 | 3.3 x 3 x 2.5 | 1500 | |

1000 | 1000 | 4.2 x 3.5 x 3.8 | 2500 |

1,The triple mixing adopts the imported frequency inverter for speed adjustment,which can meet different technological demands.

Mixing paddle

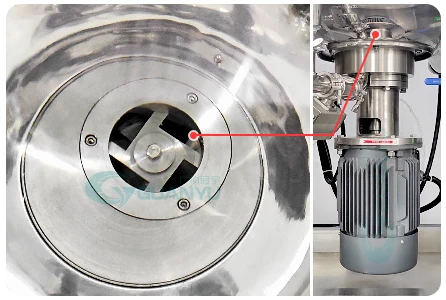

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

External circulation pipeline

Vacuum Pumps

Accessories

Oil-water pot

Console

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, chemical equipments over 20 years.Q2: Where is your factory location? How can I visit there?

A2: Our factory is located in Guangzhou, China, welcome to visit us at any time. You can take the plane to Guangzhou and then we will pick you up there.

Q3: How does your factory do regarding quality control?

A3: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q4: What’s the guarantee and the after service if we purchase from you?

A4: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q5: Are your machines difficult to operate? How do you teach us to use the machine?

A5: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines’ functions and to teach you how to use them.

Q6: Can you make the machine according to customers’ request?

A6: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer’s requirements or situation.

Reviews

There are no reviews yet.